Automatic proofing and steaming integrated machine

An all-in-one, steaming technology, used in conveyor objects, baking, dough fermenters, etc., can solve the problems of low productivity, large floor space, high energy consumption, reduce steam loss and save floor space , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

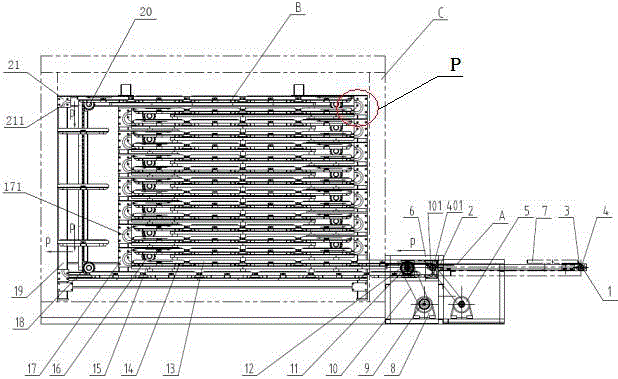

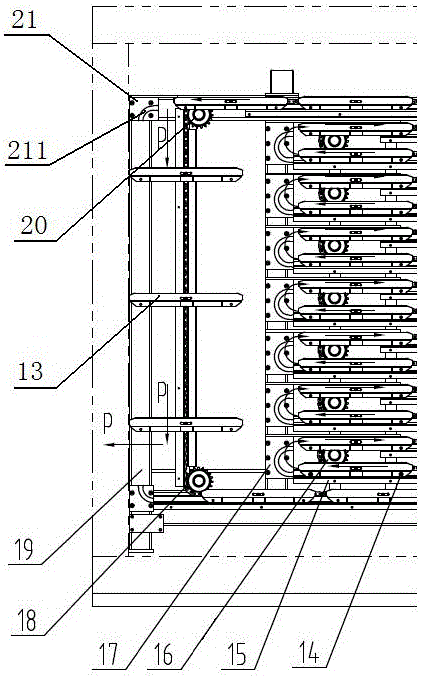

[0013] see Figure 1-Figure 3 , an automatic waking and steaming all-in-one machine according to the present invention, comprising a steaming tray input device A, a steaming tray moving device B and a waking and steaming room C, the steaming tray moving device B is installed in the waking and steaming room C, and the entrance of the There is a steaming tray input device A, which is characterized in that the steaming tray moving device B drives only the steaming tray of processed food to run along a multi-layer S-shaped track, and finally the exit from the rear end of the steaming room C will be equipped with Steam tray output for steamed processed food.

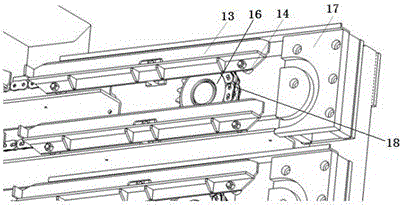

[0014] The steaming tray input device A includes a tray-in sprocket 1, a tray-in chain 2, a tray-in paddle 3, a tray-in drive motor 5 and an input frame 6, and a tray-in tray is installed at the front and back of the input frame 6. The sprocket 1 and the tray-in chain 2 are wound between the two tray-in sprockets 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com