Electrical sterilization device for machinery

A disinfection device and electrical technology, applied in the direction of disinfection, water supply equipment, sanitary equipment for toilets, etc., can solve the problems of operator injury, shorten the service life of the disinfection device, and damage the mechanical parts of the disinfection device, so as to improve the effect and improve The effect of the automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

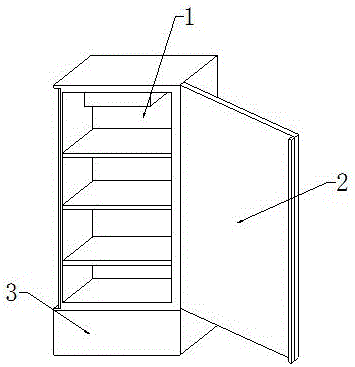

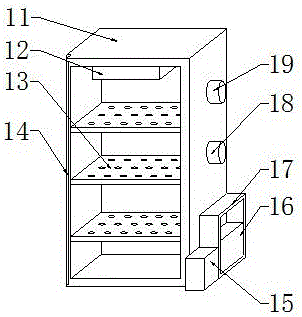

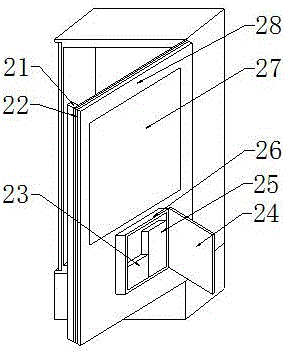

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: an electrical disinfection device for machinery, comprising a disinfection cabinet assembly 1, a cabinet door assembly 2 and an auxiliary tool assembly 3, the upper end of the auxiliary tool assembly 3 is equipped with a disinfection cabinet assembly 1, and the front end of the disinfection cabinet assembly 1 A cabinet door assembly 2 is installed.

[0025] The disinfection cabinet assembly 1 comprises a cabinet body 11, an infrared heating lamp 12, a placement plate 13, an iron block 14, a timing switch 15, a battery one 16, a casing one 17, an air outlet 18 and a nitrogen inlet 19, and the placement plate 13 is provided with three, Three placement boards 13 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com