Automobile heat exchanger main fin soldering flux coating production line

A technology for heat exchangers and production lines, applied in tin feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the qualified rate of heat exchanger cores, difficult to spray uniform flux of flux, complex shapes, etc., to save labor , full coverage, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

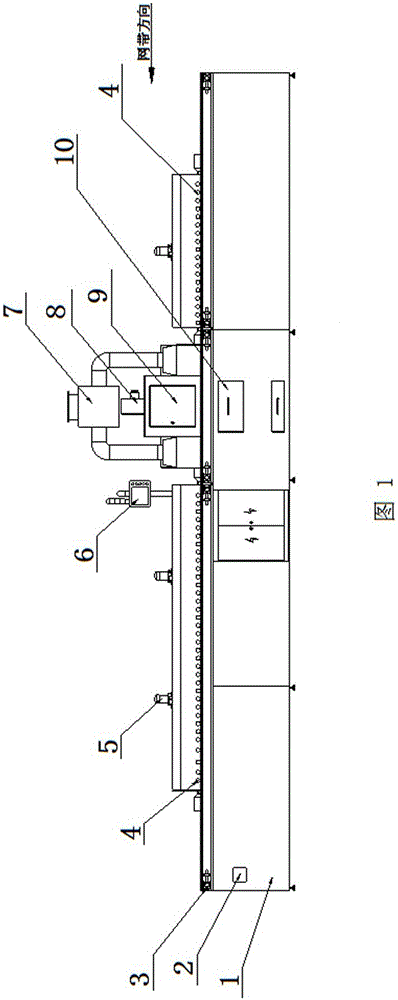

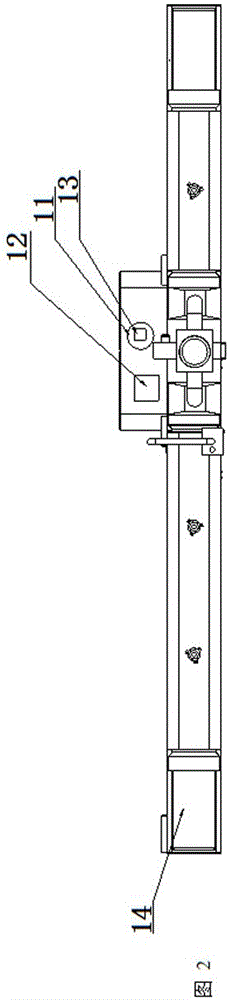

[0020] refer to Figure 1-2 , the specific embodiment adopts the following technical scheme: the production line of flux coating production line for the main sheet of automobile heat exchanger, including underframe 1, mesh belt motor 2, mesh belt tensioning seat 3, heating tube 4, drying motor 5, touch screen control Box 6, mist removal device 7, linear slide table 8, spraying box 9, flux recovery box 10, flux barrel 11, diaphragm pump 12, stirring motor 13 and mesh belt 14, mesh belt motor 2 is fixed on the chassis 1 , the mesh belt motor 2 is connected with the mesh belt 14, the mesh belt 14 two ends are provided with the mesh belt tension seat 3, the mesh belt 14 top is provided with the spray box 9, the spray box 9 top is provided with the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com