Die cover structure for welding die

A mold cover and cover body technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of ineffective removal of smoke, unsatisfactory use effect, etc., to achieve convenient fixing and detachment, and good cushioning Action, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

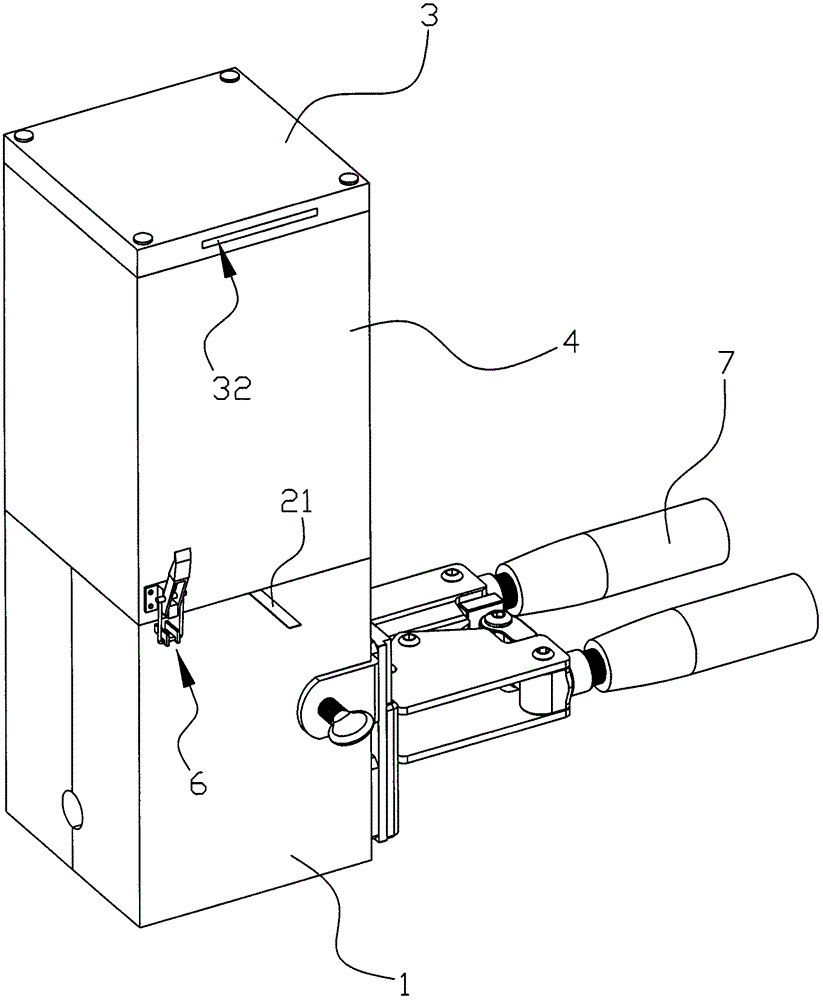

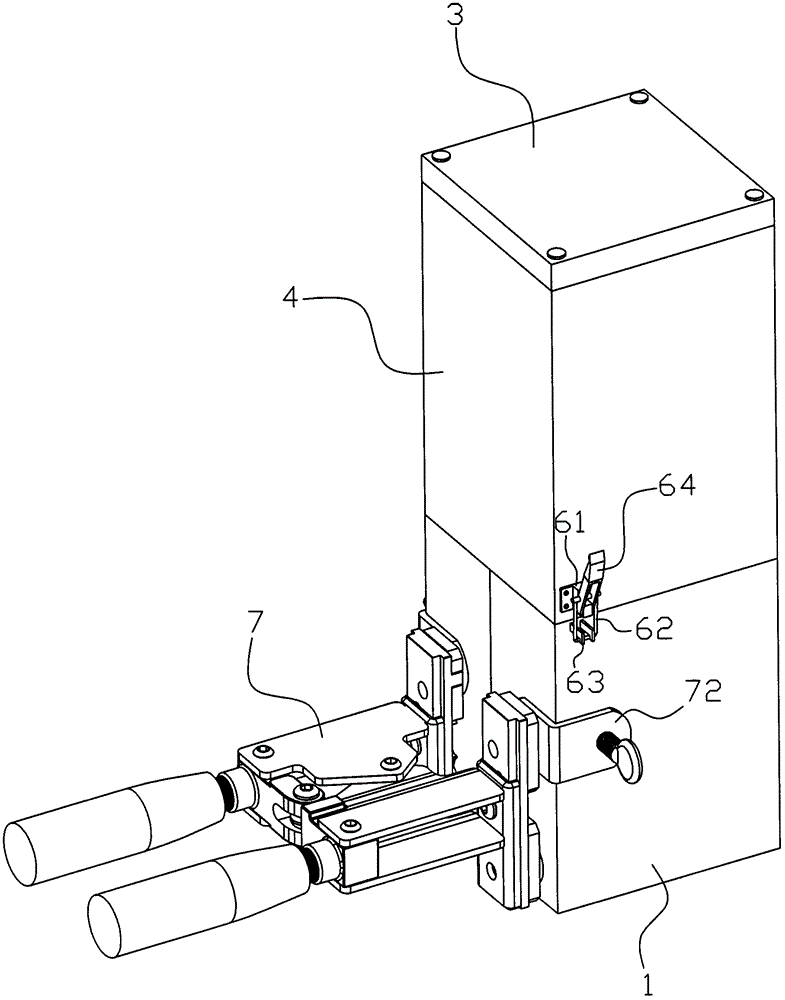

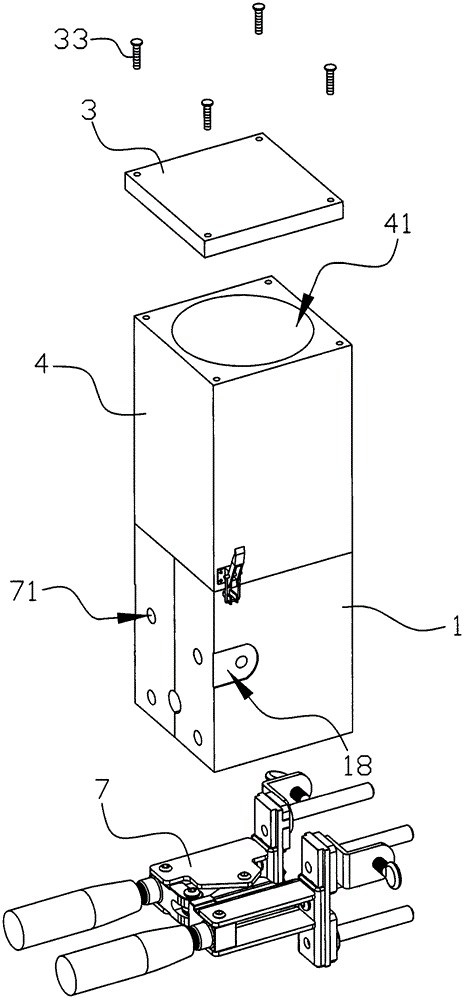

[0036] Such as Figure 1 to Figure 11 As shown, the mold cover structure of the welding mold of the present embodiment includes a mold cover shell, and a vent cavity 41 is arranged in the mold cover shell, and the vent cavity 41 communicates with the outside world through the air outlet 32. The mold cover shell The ventilation cavity 41 in the body includes a filter area and an air outlet 32 that can filter and cool down from bottom to top. 32 communicate with each other, and the air outlet 32 is located on the side of the mold cover housing top.

[0037] There are N filter areas, and N is a natural number greater than or equal to 2; when N is a natural number 2, the filter area includes a metal wire filter area 46 and an organic polymer filamentary filter area 47, and the metal wire filter area 46 is connected with an organic filter area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com