Cutting device for material cut-off

A cutting device and material technology, applied in the direction of making medicines into special physical or ingestible devices, metal processing, etc., can solve the problems of high labor intensity, low efficiency, large resistance, etc., and achieve low manufacturing costs and smooth production lines , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

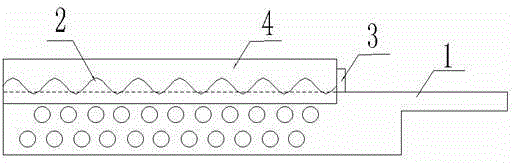

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The cutting device for material cutting is composed of a cutter body 1 and a heating device.

[0014] Such as figure 1 As shown, the structure of the cutting device for material cutting is as follows: the heating device is composed of a heating wire 2, a temperature control switch 3 and a casing 4, and the heating wire can effectively prevent the knife from sticking. There are several or more hollow holes distributed on the cutter face of the cutter body 1 . The knife holes are distributed in two parallel rows on the knife face. The diameter of the knife hole is 8mm, the interval is 10mm, and there are 22 holes in total, which can effectively reduce the friction when cutting. The area of the knife hole is at least 1 / 3 of the area of the knife face.

[0015] The use state of the cutting device for material cutting: when the knife cuts into the medicine block, sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com