Microwave-absorbing composite material with discontinuous impedance gradient structure

A technology of composite materials and impedance gradual change, which is applied in the direction of layered products, chemical instruments and methods, coatings, etc., can solve the problems such as the effect is not obvious, and achieve the effect of good wave absorption ability, light weight, and strong electromagnetic wave loss ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

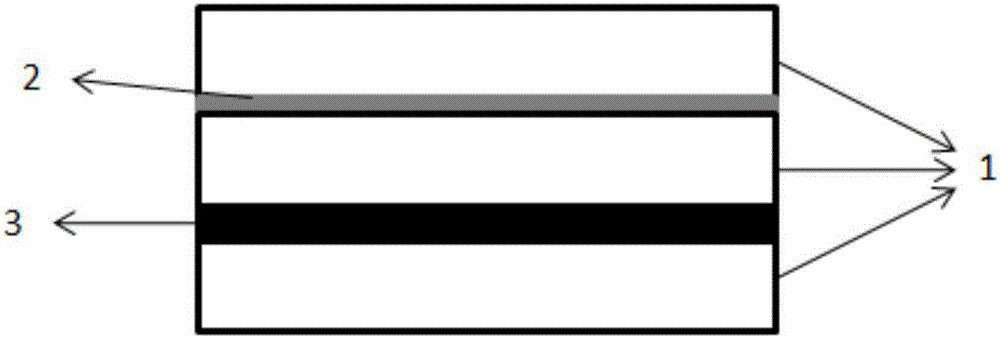

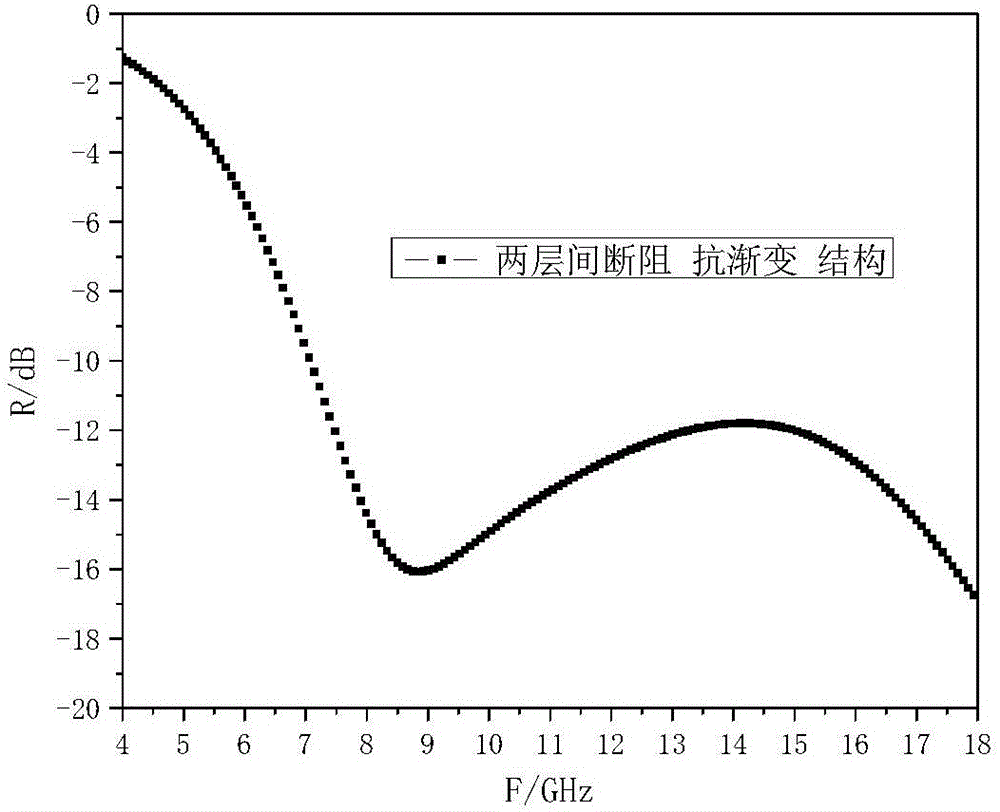

[0024] Use 4mm length, T700 type chopped carbon fiber as absorbent, two layers of electric loss layer chopped carbon fiber concentration ratio is 3:50, thickness ratio is 1:2, resin matrix is epoxy resin, reinforced fiber cloth is QW220F, spraying The process distributes the chopped carbon fibers evenly on each layer of fiberglass cloth. The number of layers of fiber cloth used is 18, and the molding method is adopted, and the thickness of the formed composite material is 3.8mm. Schematic diagram of the structure of the absorbing composite material figure 1 , the absorbing performance curve is as follows figure 2 .

example 2

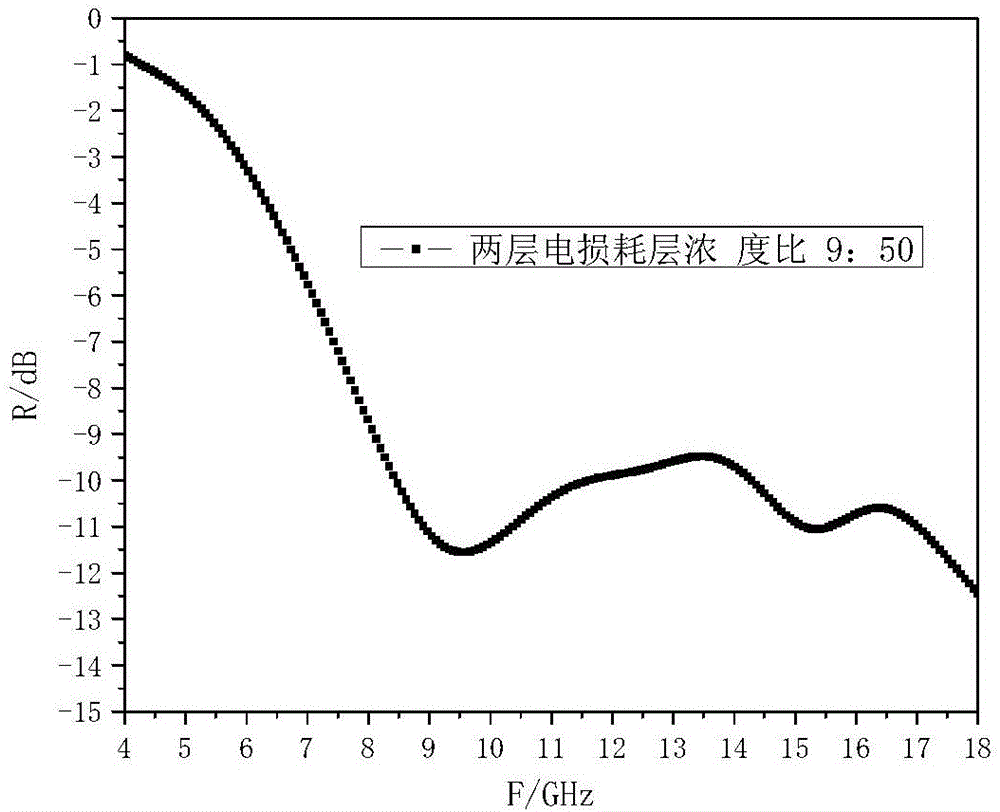

[0026] Use 4mm length, T700 type chopped carbon fiber as absorbent, two layers of electric loss layer chopped carbon fiber concentration ratio is 9:50, thickness ratio is 1:2, resin matrix is epoxy resin, reinforced fiber cloth is QW220F, spraying The process distributes the chopped carbon fibers evenly on each layer of fiberglass cloth. The number of fiber cloth layers used is 20, and the compression molding method is adopted, and the thickness of the formed composite material is 4.0 mm. Schematic diagram of the structure of the absorbing composite material figure 1 , the absorbing performance curve is as follows image 3 .

example 3

[0028] Use 4mm length, T700 type chopped carbon fiber as absorbent, two layers of electric loss layer chopped carbon fiber concentration ratio is 3:60, thickness ratio is 1:2, resin matrix is epoxy resin, reinforced fiber cloth is QW220F, spraying The process distributes the chopped carbon fibers evenly on each layer of fiberglass cloth. The number of fiber cloth layers used is 21, and the compression molding method is adopted, and the thickness of the formed composite material is 4.1mm. Schematic diagram of the structure of the absorbing composite material figure 1 , the absorbing performance curve is as follows Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com