Damping and damper selection method for reducing wheel tread failure in rail transit

A technology for wheel tread and rail transportation, which is used in railway car body parts, bogies, axle box installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

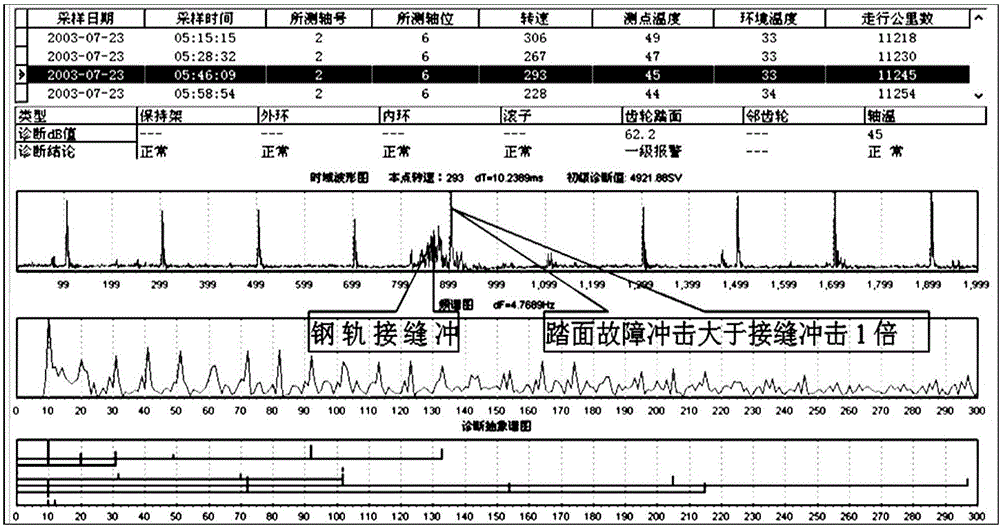

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

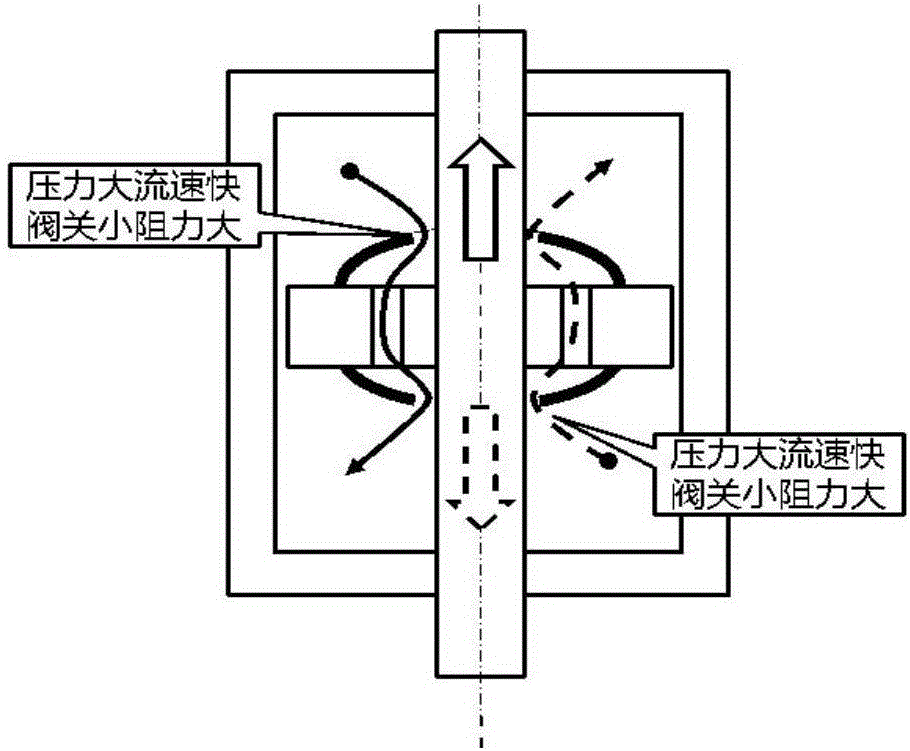

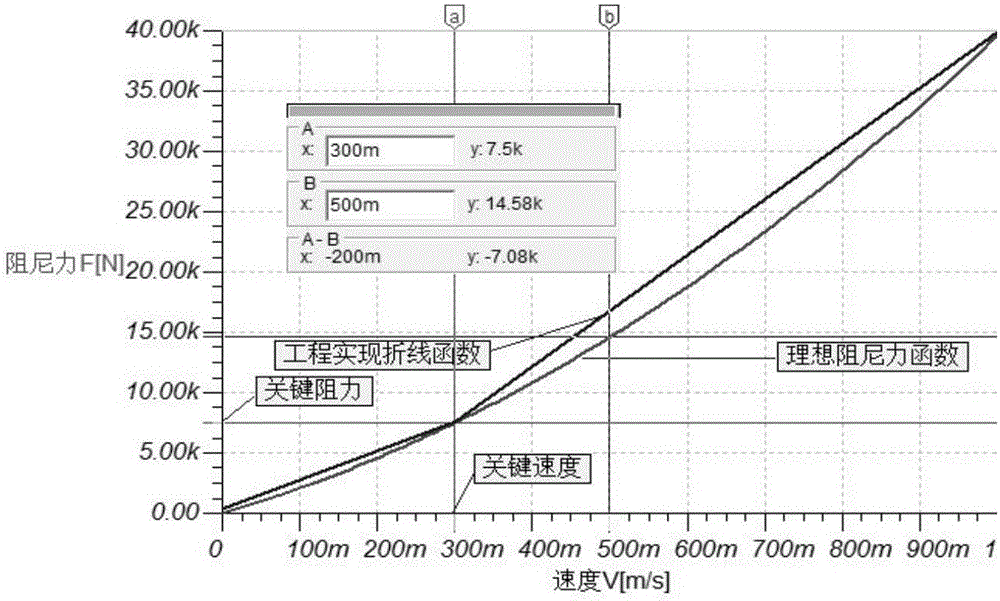

[0056] A damping and damper selection method for reducing rail traffic wheel tread faults is characterized in that the absolute value of the damping force F is selected to a positive nonlinear damper with a constant or increasing coefficient of change rate of the absolute value of the vibration velocity V; When the vibration damping object is damped when the polarity of the vibration velocity V is positive or negative, the polarity of the damping force F is always opposite to the polarity of the vibration velocity V, replacing the existing positive polarity of the vibration velocity V Satisfy the rate of change of the absolute value of the damping force F to the absolute value of the vibration velocity V is constant, but when the vibration velocity V is negative, the rate of change of the absolute value of the damping force F to the absolute v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com