Automatic photoetching plate feeding and taking device of chip photoetching machine

A technology of retrieving device and photolithographic plate, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to meet the requirements of photolithography, wear or tear of the plate film, easy wear and tear, etc., and achieve good photolithography effect, to ensure proper functioning, to avoid wear or tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples.

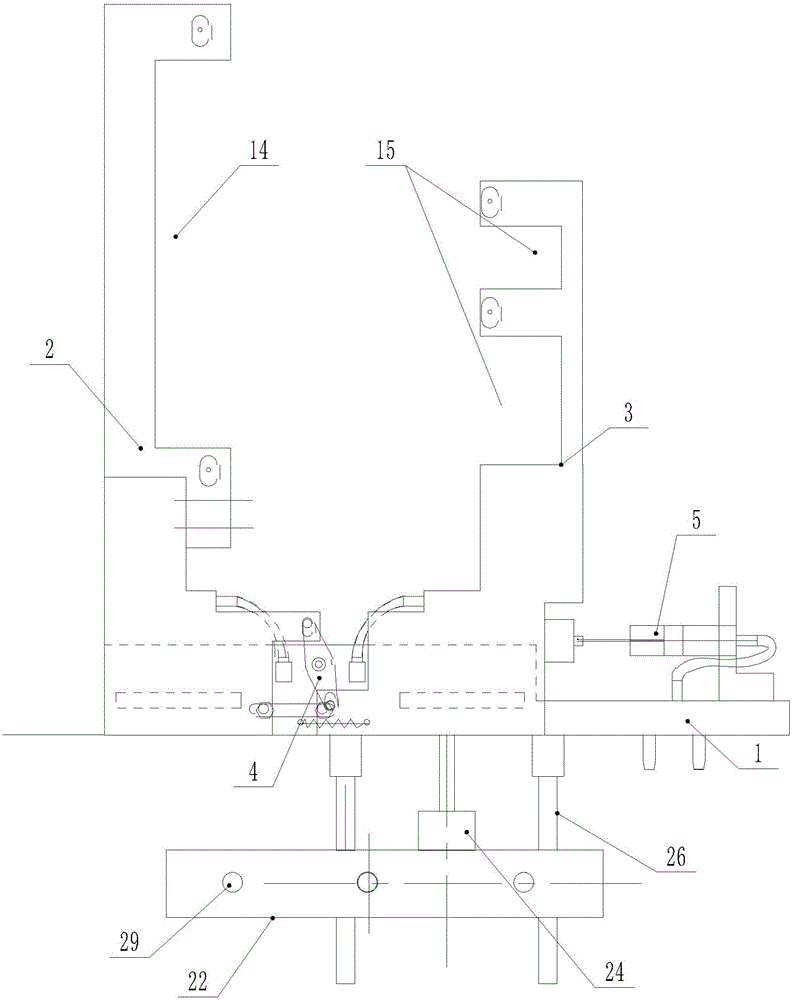

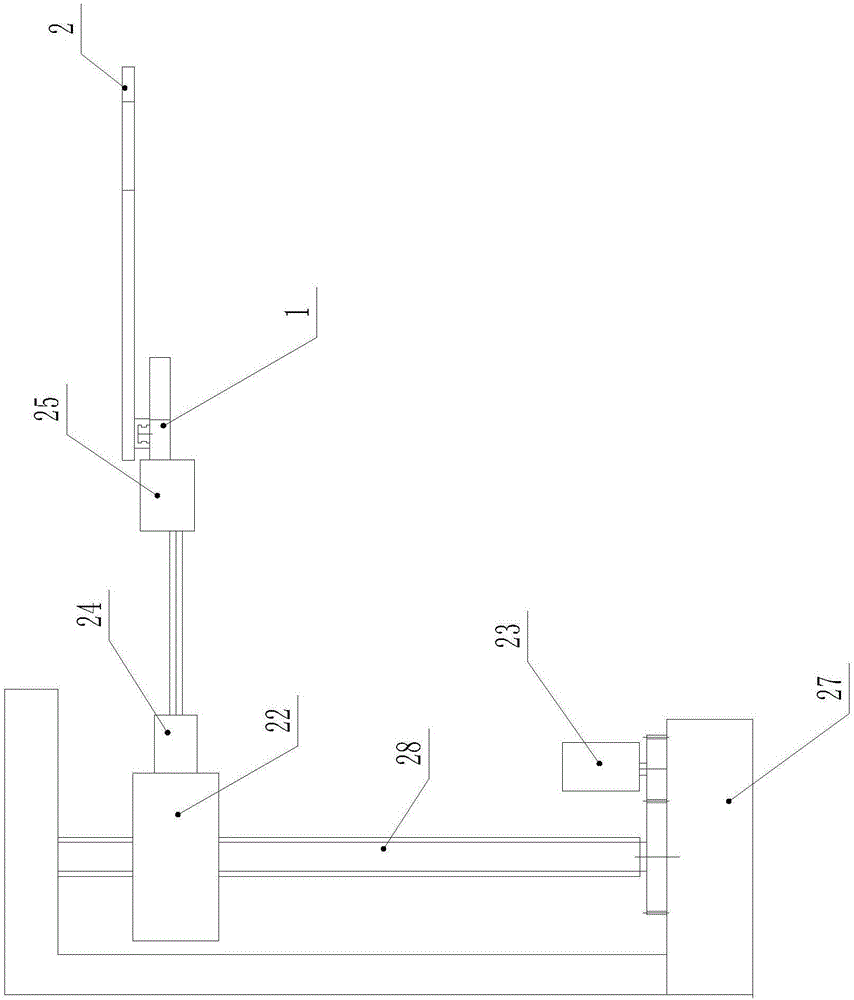

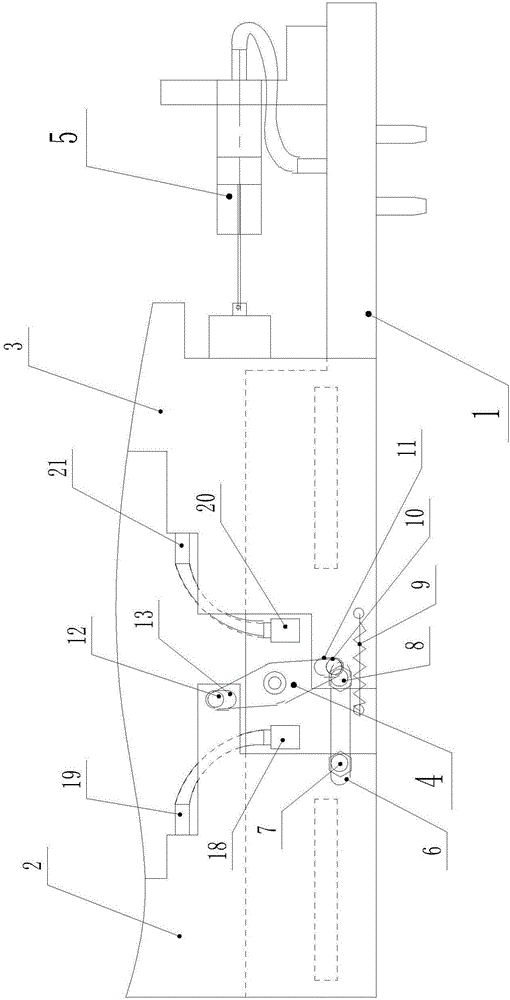

[0025] Such as Figure 1 to Figure 4 As shown, a photolithography plate 16 automatic feeding and retrieving device of a chip photolithography machine includes a machine base 27, and a lifting seat 22 driven by a lifting power device is installed vertically on the machine base 27. Specifically, the The lifting power device includes a lifting motor 23 and a screw 28 nut mechanism. Two columns 29 are fixed on the base 27, and the lifting seat 22 is slidably fitted on the column 29, thereby constraining the lifting seat 22 to only slide vertically. And can not deflect horizontally, and described lifting motor 23 is installed on the support 27, and the leading screw 28 vertical rotation of described leading screw 28 nut mechanisms is installed on the support 27, and the nut of described leading screw 28 nut mechanisms is fixed on On the lifting seat 22, the lifting motor 23 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com