Method for sterilization control over detergent box of washing machine and washing machine

A technology of detergent box and control method, which is applied to the control device of washing machine, other washing machines, washing devices, etc., which can solve the problems of clothing pollution, peculiar smell of liquid storage box, and intrusion, and achieve increased comfort, simple structure, and guaranteed clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

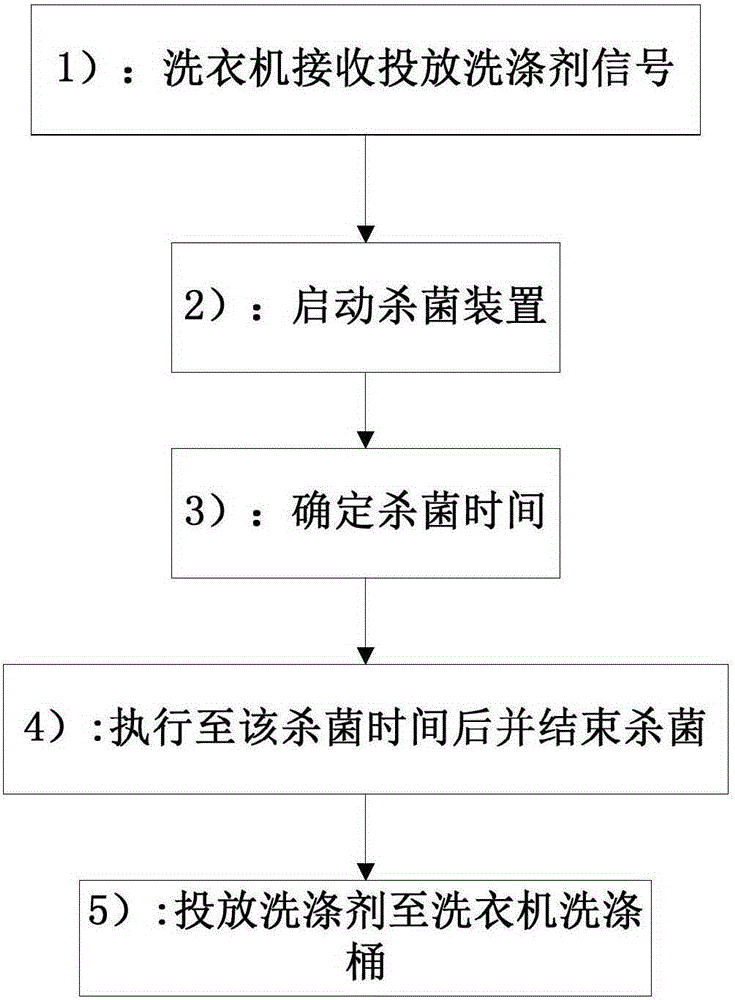

Embodiment 1

[0039] In this embodiment, the sterilizing device adopts an ultraviolet sterilizing lamp to kill bacteria growing in the detergent box through ultraviolet irradiation. In this embodiment, the ultraviolet germicidal lamp is set as a short-wave germicidal ultraviolet light, which has weak penetrating ability and cannot penetrate the plastic material used to make the detergent box, so it will not cause harm to users and ensure the safety of the washing machine.

[0040] In this embodiment, since the interior space of the detergent box is small, direct irradiation at 254 nm can completely cover the interior space, avoiding the air pollution caused by ozone diffusion caused by the strong sterilizing effect of too short ultraviolet rays and the aging of washing machine components.

[0041] In this embodiment, the ultraviolet germicidal lamp adopts a smaller LED lamp, and at least one ultraviolet germicidal lamp is set on the top of the detergent box or at a higher position on the sid...

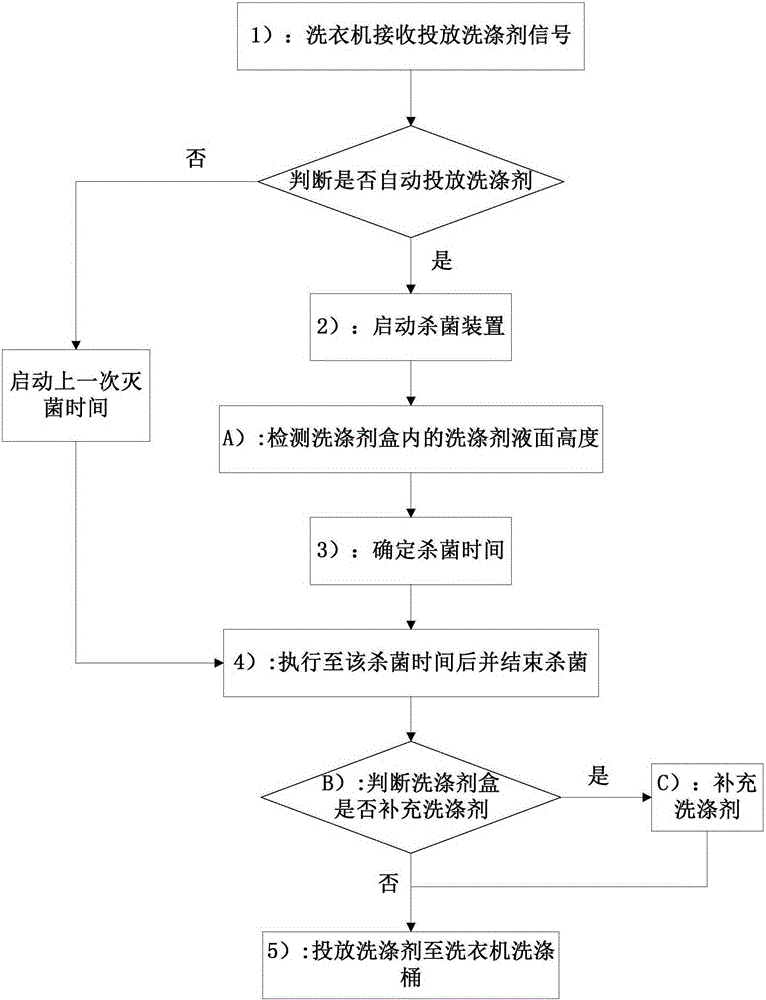

Embodiment 2

[0050] Such as figure 2 As shown, in the present embodiment, the detergent box is provided with a judging unit for judging the liquid level of the detergent, and

[0051] Before step 1), or between step 1) and step 2), or between step 2) and step 3), step A) is added to detect the liquid level of detergent in the detergent box. By detecting the liquid level of detergent in the detergent box, the specific situation in the detergent box can be understood, and the efficiency of sterilization can be further improved and the effect of sterilization can be ensured.

[0052] The judging unit of the washing machine in this embodiment can detect the liquid level of the detergent by installing a detection device on the detergent box, and then calculate the sterilization time of the detergent box sterilization device of the washing machine through the main controller. The detection device may be composed of a liquid level sensor or a detection device.

[0053] The judging unit of the ...

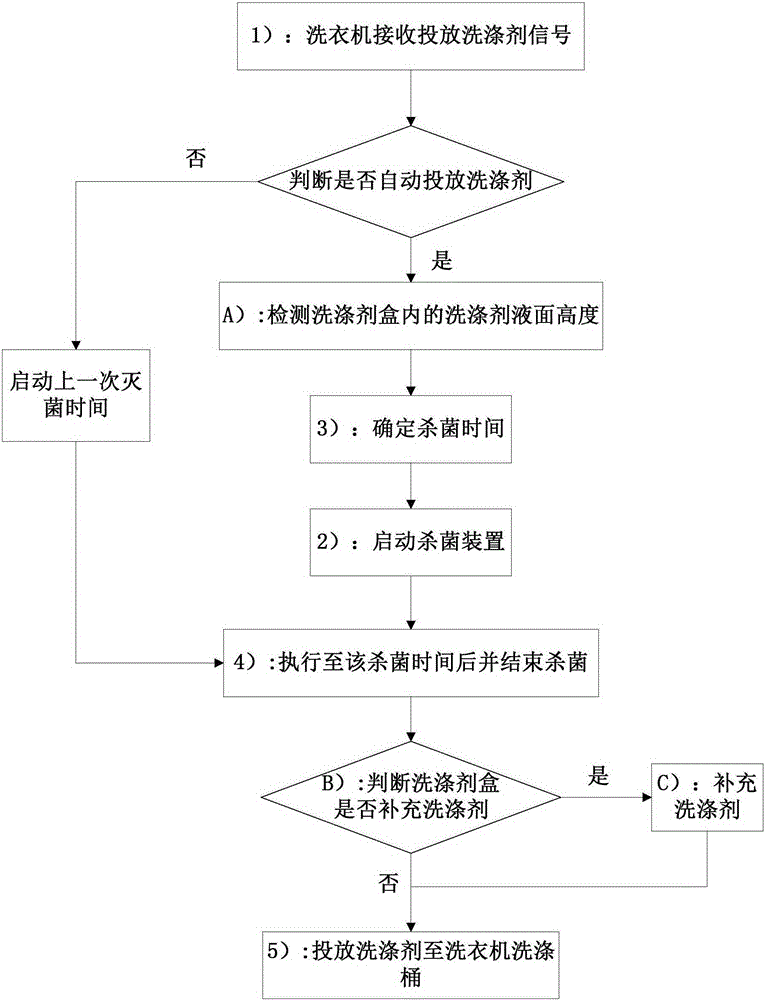

Embodiment 3

[0056] In this embodiment, because the detergent in the detergent box is less, the area of the detergent box exposed to air is more, and the inner surface of the detergent box will be more likely to breed bacteria.

[0057] Therefore, in step 3) of the washing machine detergent box sterilization control method in this embodiment, the sterilization time is mainly determined according to the liquid level of detergent in the detergent box.

[0058] In this embodiment, when the liquid level of the detergent in the detergent box is detected as L, the sterilizing working time is calculated as T. The size of the area of the washing box in contact with the air can be judged by the liquid level of the detergent, so as to determine the sterilization time.

[0059] Preferably, when the liquid level L is getting smaller and smaller, the sterilization time T is getting longer. Adopting the method in this embodiment can ensure that the detergent box is fully sterilized. Since the deterge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com