A critically unlocked vertical shock-isolation bearing and method

A vertical vibration isolation and unlocking technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber-spring combination, etc., can solve problems such as reducing vertical stiffness, achieve good vertical support, good isolation shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

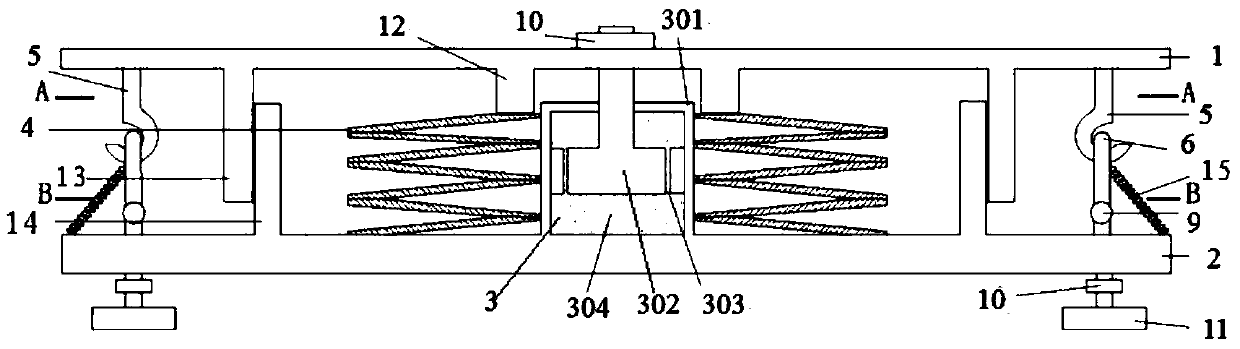

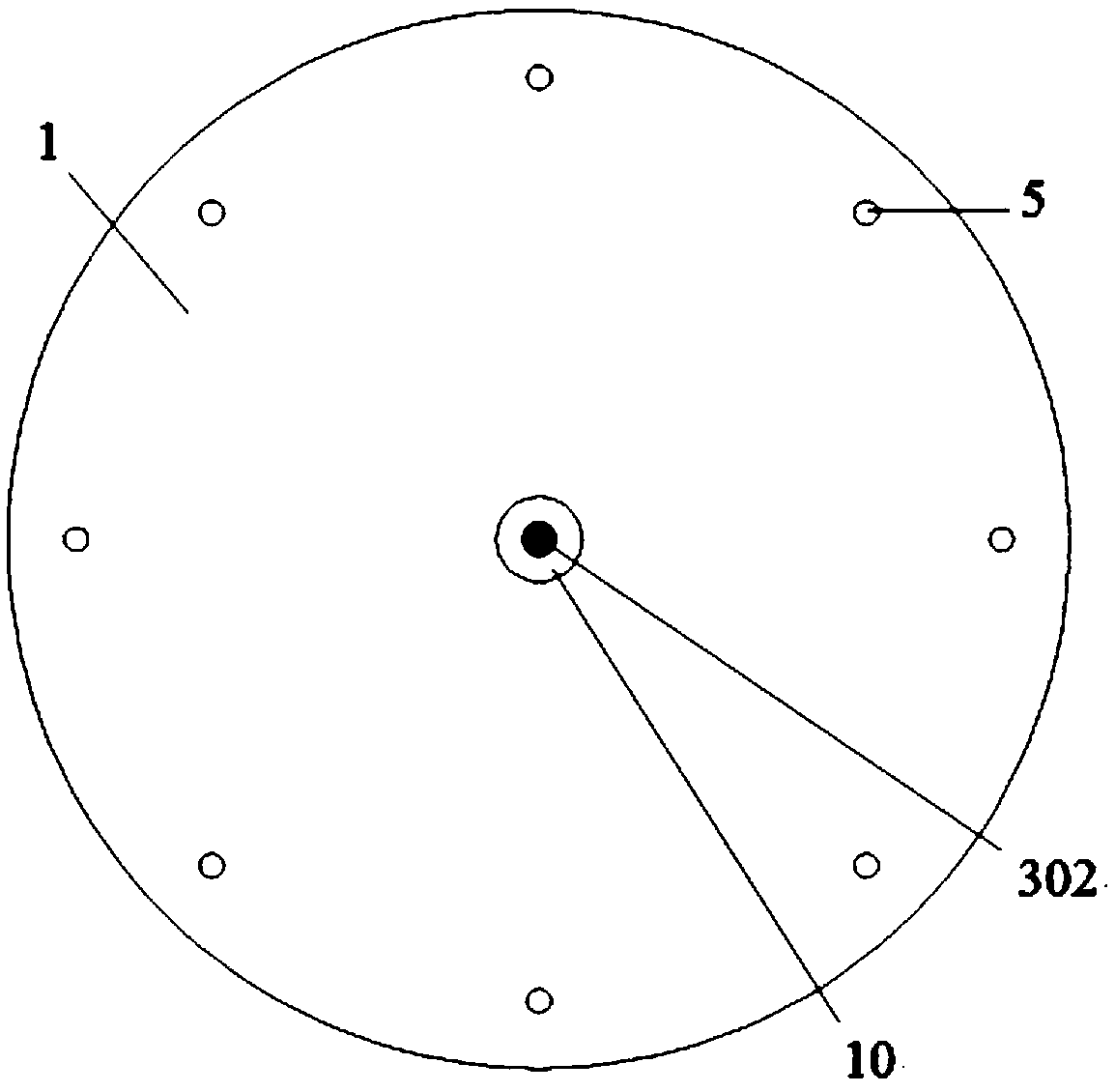

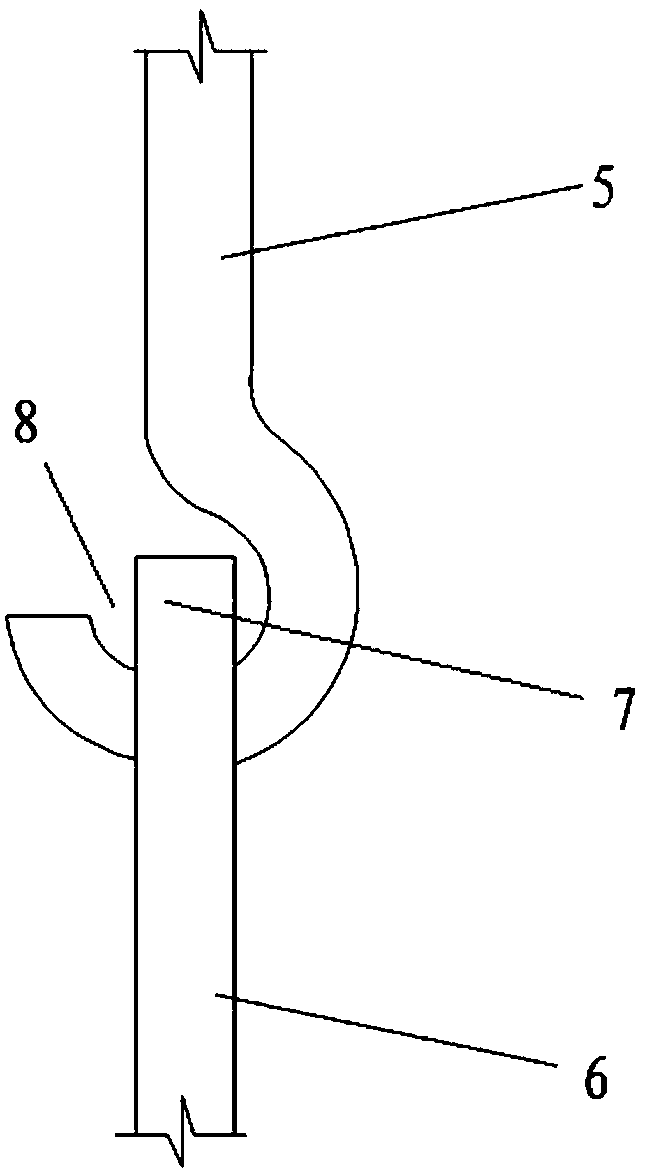

[0036] See figure 1 and figure 2 , the critically unlocked vertical shock-isolation bearing of the first embodiment includes an upper support plate 1, a lower support plate 2, and a damper 3 and a first elastic member located between the upper support plate 1 and the lower support plate 2 4. The upper support plate 1 protrudes a first locking part toward the lower support plate 2, and the lower support plate 2 protrudes a second locking part toward the upper support plate 1, and the first locking part and The second locking part is provided with a locking tongue 7 and a locking hole 8 which cooperate with each other, and the first locking part and the second locking part can be rotated relative to each other, so that the locking tongue 7 can be inserted into or out of the locking hole 8. Lock hole 8; when the lock tongue 7 is inserted into the lock hole 8, the upper support plate 1 and the lower support plate 2 are relatively locked, and the first elastic member 4 is locked...

Embodiment 2

[0083] The difference from Embodiment 1 is that in Embodiment 2, one of the first locking component and the second locking component is a buckle, and the other is a hook; the locking hole 8 is The hole surrounded by the main body of the buckle, the lock tongue 7 is the hook of the hook.

[0084] Wherein, the difference between the buckle and the hook is that the lock hole 8 formed by the buckle is a complete hole rather than a partially opened hole. At this time, in order to realize the unlocking between the lock hole 8 and the dead bolt 7, the second elastic member 15 can be used to drive the locking part where the buckle is located to rotate, and the second elastic member 15 can be used to drive the lock where the dead bolt 7 is located. Tight parts turn. Certainly, the lock buckle can be arranged on the first locking part or on the second locking part.

[0085] Wherein, in order to distinguish partially open holes from completed holes, it is conceivable that a hole surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com