An Ultrasonic Detection Method of Surface Residual Stress Based on Directly Coupled Wave Generation

A residual stress and ultrasonic detection technology, applied in force/torque/work measuring instruments, measuring force, measuring devices, etc., can solve the problems of poor signal-to-noise ratio and fast attenuation of sound energy during sound, so as to ensure calculation accuracy, Ease of operation and the effect of ensuring the quality of the received signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail in conjunction with the drawings and technical solutions.

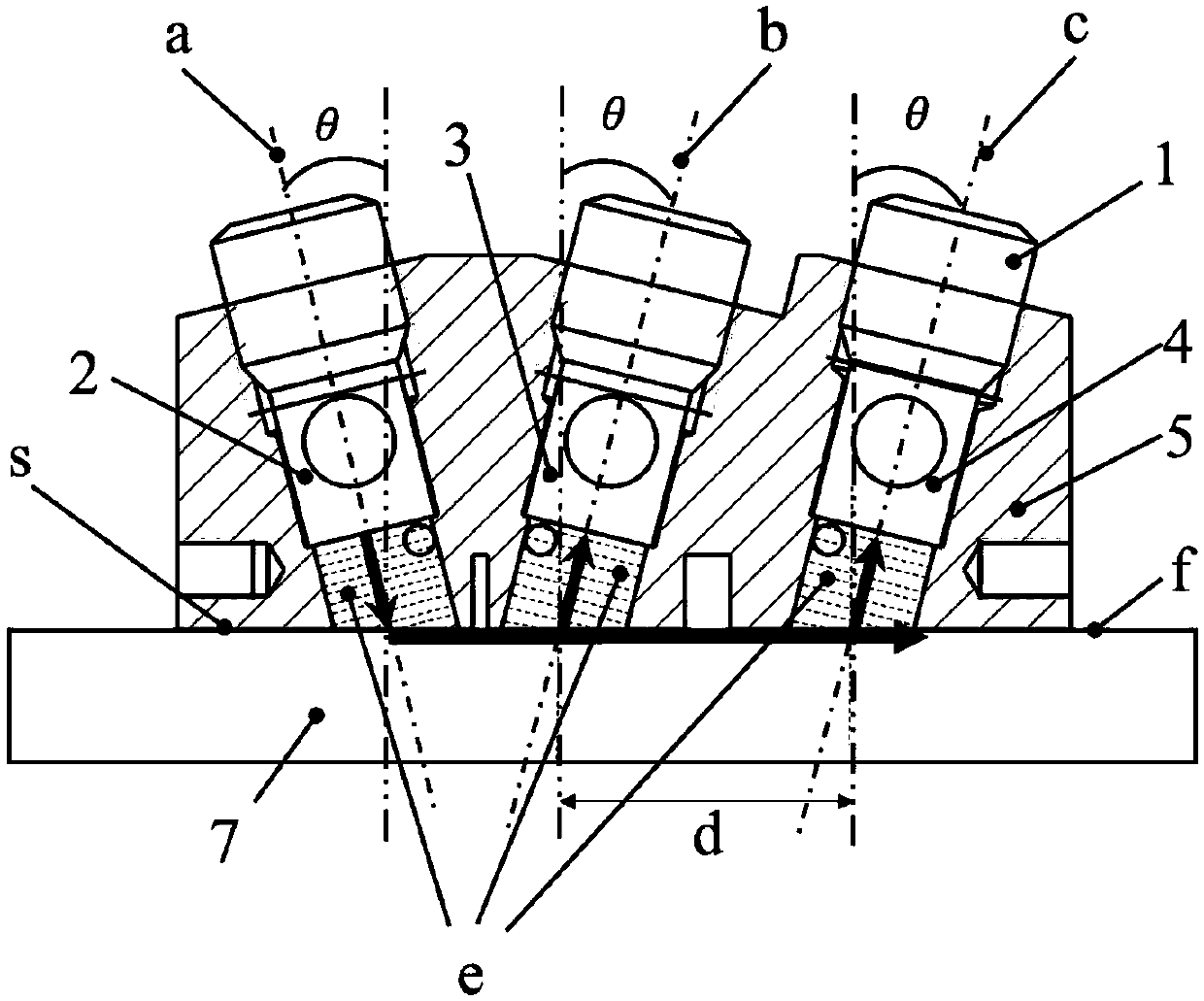

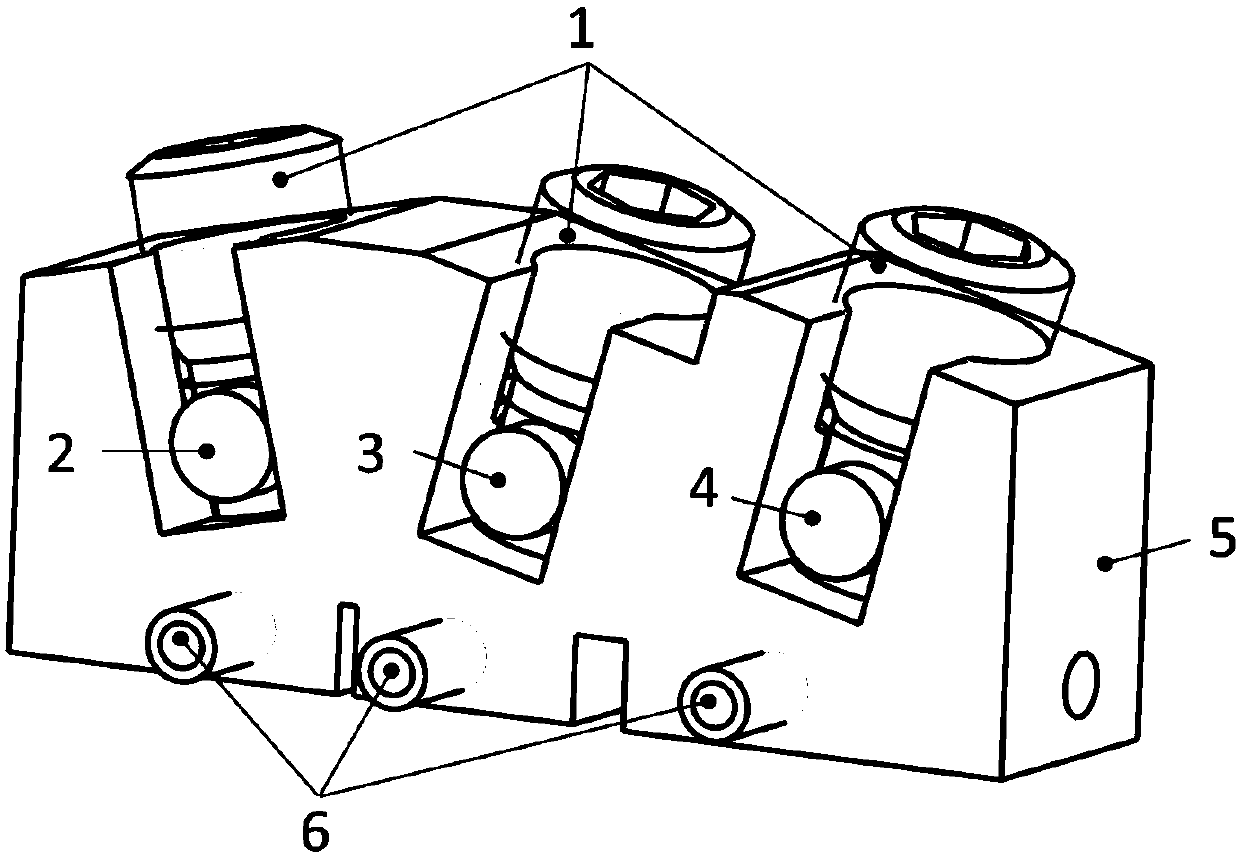

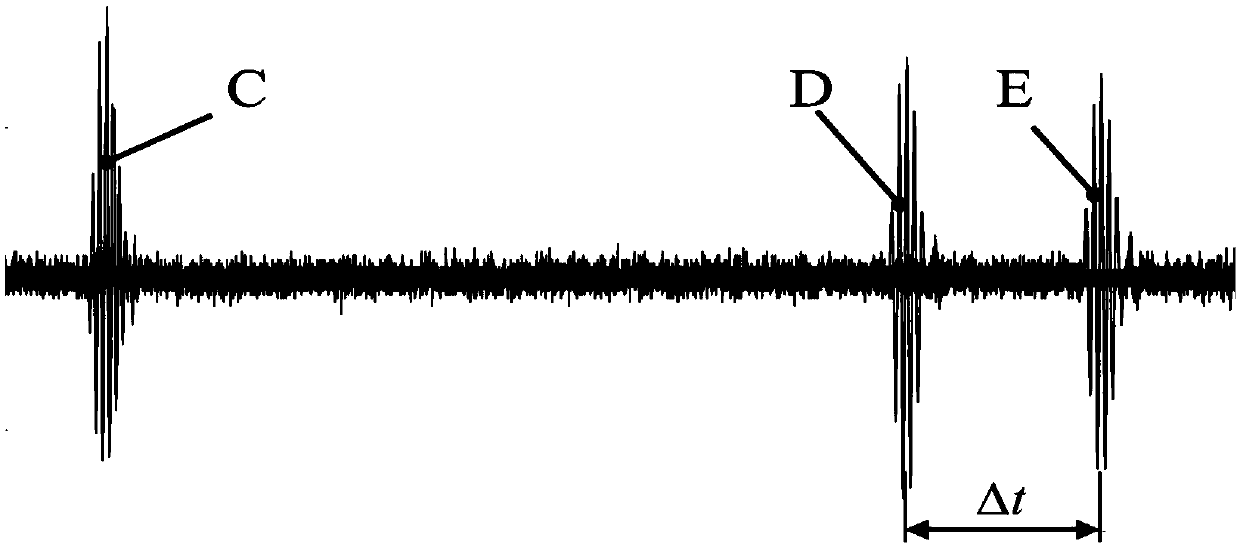

[0024] Key parameters and assembly of the direct-coupled wave-making ultrasonic probe: pure water is used as the coupling agent, and the material to be tested is 5052 aluminum alloy; The medium sound velocity is 6320m / s, and the first critical angle θ is calculated as 13.70° when brought into equation (1); the measurement distance d is 19mm; the geometric relationship of each part of the ultrasonic probe is as attached figure 1 shown. The transmitting transducer 2, the first receiving transducer 3 and the second receiving transducer 4 are respectively embedded and installed in the probe base 5 along the incident axis a, the first receiving axis b and the second receiving axis c, and are respectively fixed by bolts Component 1 is fastened to complete the assembly of the direct-coupled wave-making probe. figure 2 It is the overall assembly dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com