Vertical multiple-degrees-of-freedom high-precision detector for detecting comprehensive performance of precision reducers

A precision reducer, comprehensive performance technology, used in the testing of machine/structural components, machine gear/transmission mechanism testing, instruments, etc. Reduce the difficulty of traceability and error compensation, and reduce the effect of shell deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

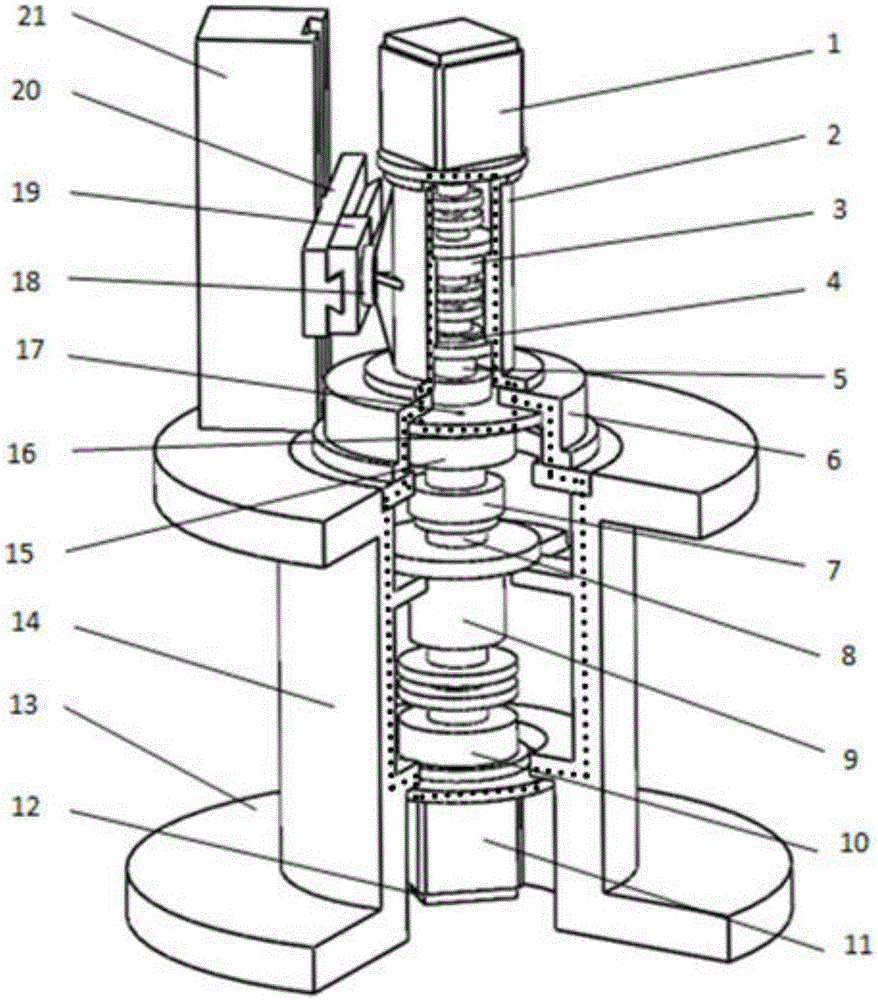

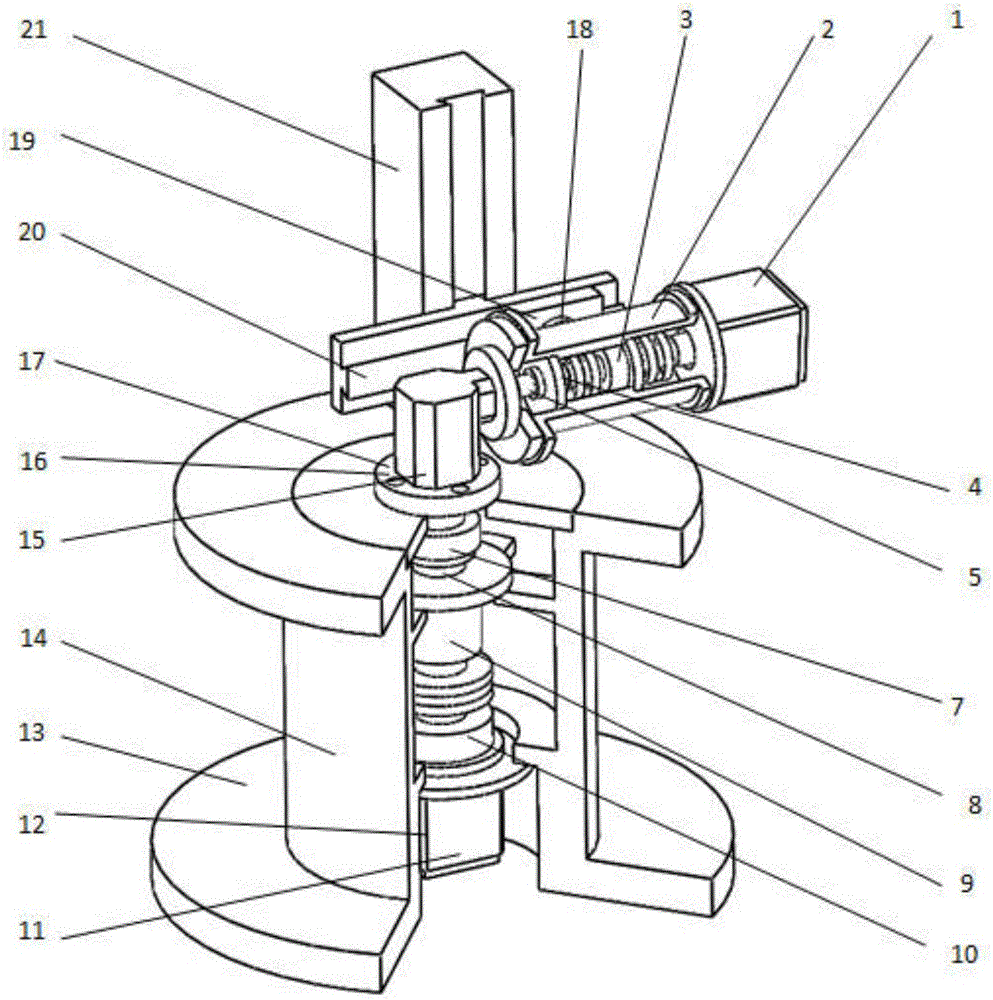

[0017] see Figure 1 ~ Figure 2 , a vertical multi-degree-of-freedom high-precision detector for the comprehensive performance of precision reducers, including a high-speed end torque closure module, an attitude adjustment module and a low-speed end torque closure module.

[0018] The low-speed end torque closure module includes a vertically arranged low-speed end torque closure cylinder 14, and an eversion support seat 13 is provided at the bottom of the low-speed end torque closure cylinder 14, and inside the low-speed end torque closure cylinder 14, the The top is sequentially provided with a loading motor 11, a booster reducer 10, a low-speed end torque sensor 9, a low-speed end circular grating 8, and a reducer output shaft transfer inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com