Site disposal robot for coping safety risk accidents in plane zone scale

A security risk and robotics technology, applied in the field of robotics, can solve the problems of lack of on-site immediate disposal means, slow response to risk events, and large manpower and material resources, so as to facilitate mass production and application, reduce personal injury or property loss, The effect of eliminating potential hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

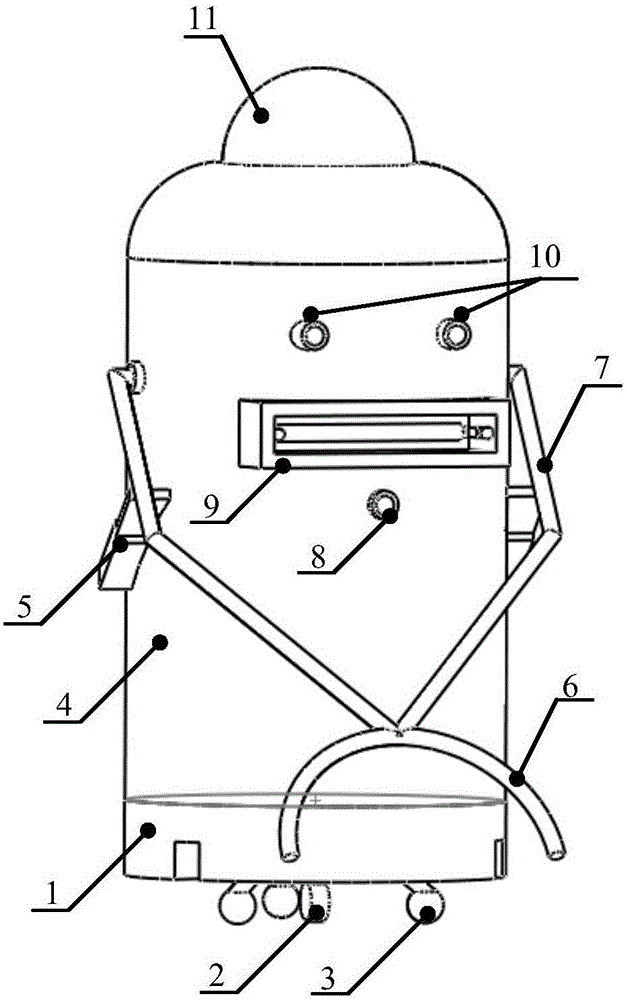

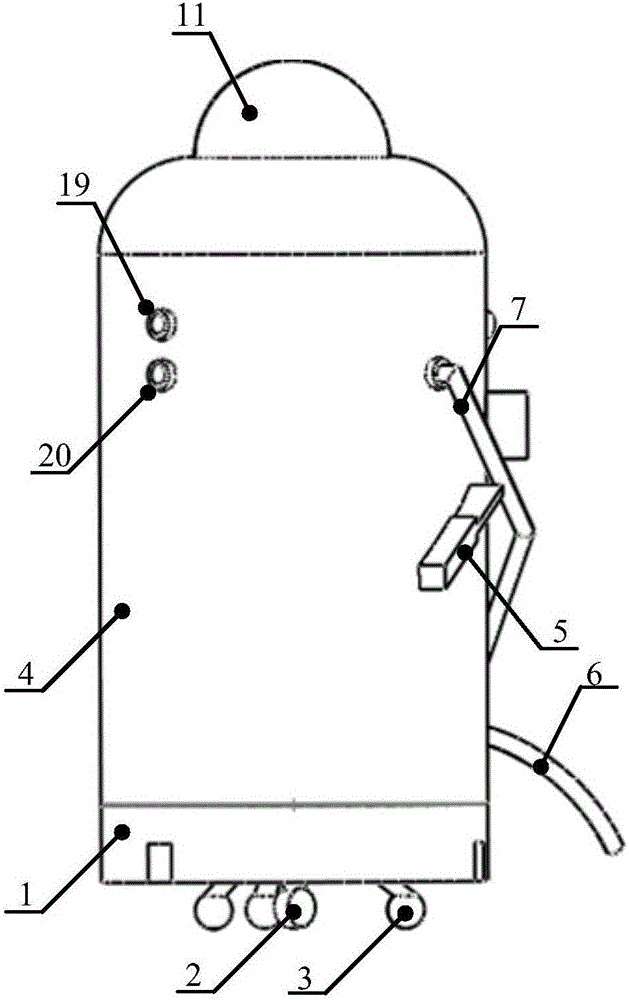

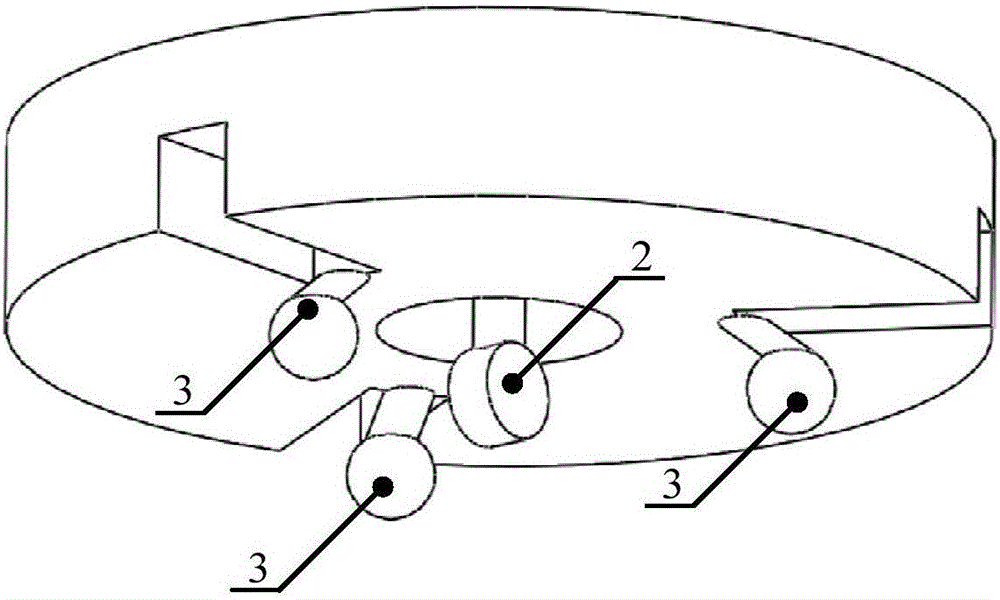

[0036] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention includes a wheeled electric drive chassis 1, an electrically controlled rotatable cavity 4, a fire extinguisher 14, a smoke barrel 15, a power supply device 13, a switchable spray device for fire protection or smoke, a steel fork device with electric shock, and a power grid capture Device 9, panoramic video monitoring device 11 and central control device 18; wherein:

[0037] The electronically controlled rotatable cavity 4 is installed on the wheeled electric drive chassis 1, the steel fork device with electric shock is installed on the outer side of the electrically controlled rotatable cavity 4, and the panoramic video monitoring device 11 is installed on the top of the electrically controlled rotatable cavity 4; The outer surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com