Solid laser quality improving method based on in-cavity phase conjugate

A solid-state laser, phase conjugation technology, applied in lasers, laser parts, lasers using scattering effects, etc., can solve the problems of high requirements on mirror materials, complex systems, and expensive adaptive optics systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

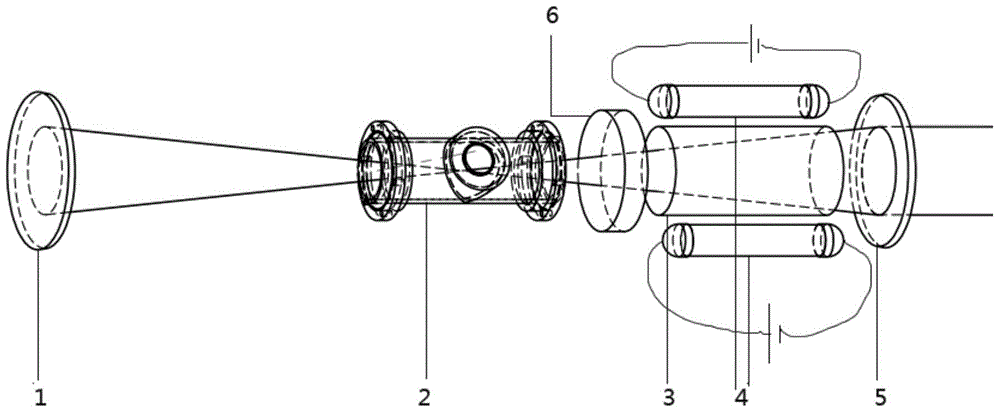

[0016] The device used in Example 1 is as figure 2 shown. Two f=1m spherical mirrors are used to form a concentric cavity with a distance of 1m. The rear cavity mirror marked 1 is specifically a silver-plated total reflection mirror, and the output coupling mirror marked 5 is specifically a half mirror with a coupling rate of 55%. Placed in the cavity from front to back are:

[0017] Two xenon lamps are used as pumping sources4.

[0018] Neodymium glass is used as the solid gain medium 3; its diameter is 10 mm, and its length is 9 cm; the Nd doping concentration is 1%.

[0019] A Fabry-Perot etalon with a thickness of 0.7 mm and a reflectance of 70% on both sides is used as the line width narrowing device 6 .

[0020] Brillouin medium gas pool as Brillouin medium 2. Stainless steel is used as the main material, fused silica is used as the window, and the interior is filled with SF 6 Or high-pressure gas such as perfluorocarbon; can be filled with appropriate buffer gas....

Embodiment 2

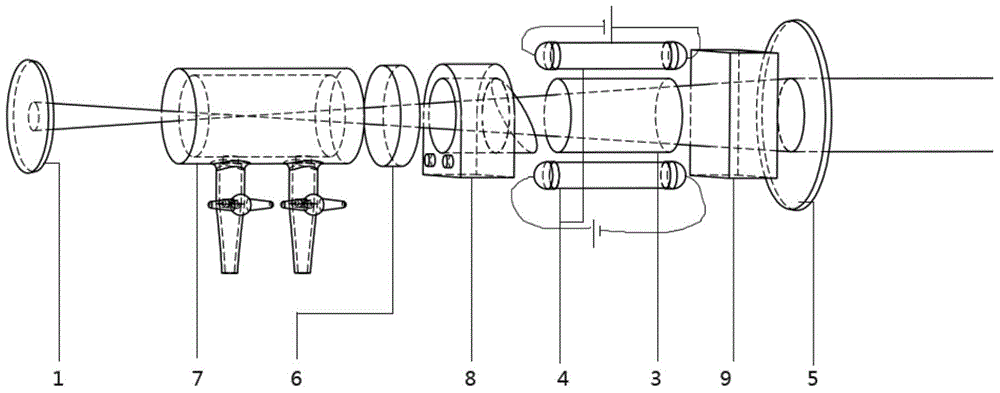

[0023] The schematic diagram of the device in Example 2 is attached image 3 shown. Two mirrors are used to form a real confocal cavity with a distance of 1.2m. The rear cavity mirror 1 is specifically a silver-plated high-reflection mirror with f=300mm, and the output coupling mirror 5 is specifically a coated mirror with f=900mm, HR@1064nm, and HT@532nm.

[0024] Inside the resonator from back to front are:

[0025] The liquid medium pool 7 is used as a Brillouin medium, filled with a Brillouin medium liquid such as CS 2 , CCl 4 Wait. The liquid in the pool can flow through the external pump through the two pistons.

[0026] A Fabry-Perot etalon with a thickness of 0.7 mm and a reflectance of 70% on both sides is used as the line width narrowing device 6 .

[0027] The Q switch 8 made of electro-optic crystal and Brewster window is used to form high peak power pulse laser.

[0028] Two xenon lamps are used as pumping sources4.

[0029] Nd-doped yttrium aluminum garne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com