White tea production line and carding machine adopted by same

A technology of stripping machine and production line, which is applied in the field of stripping machines, can solve the problems of broken shape, irregularity, and non-specification requirements for the inclination of tea leaves, and achieve the effect of complete leaf bottom and fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

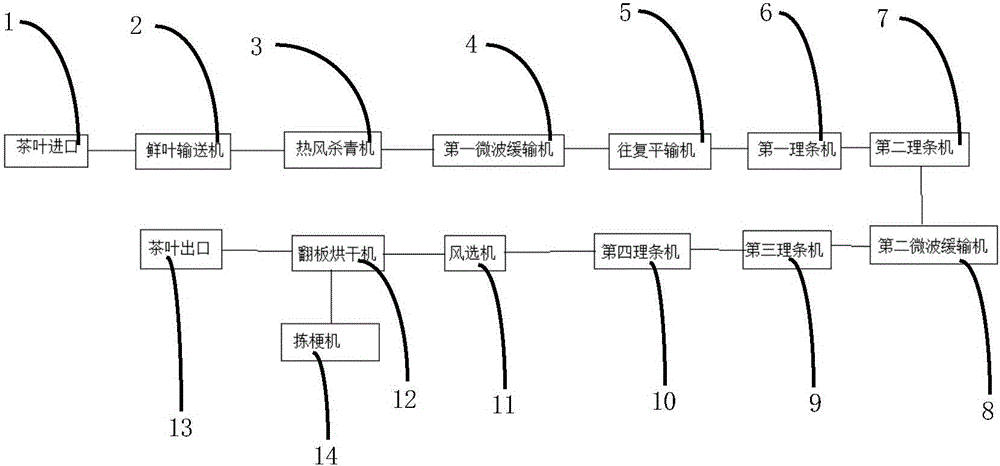

[0023] The tea leaves are input from the tea inlet 1, and are transported to the next process through the fresh leaf conveyor 2, and the tea leaves are softened and the moisture in the fresh leaves is reduced through the hot air degreening machine 3, and then transported to the first processing through the tea hoist. Strip machine 6, adjust the inclination of the first strip machine 6 to be 18°, so that the water evaporation rate of the tea leaves will not be too fast or too slow, and the final tea leaves will be kept at 50% dry, and the second strip machine 7 will be adjusted again The inclination of the tea leaves is 17°, so that the tea leaves quickly pass through the second slitting machine 7, and under the action of the pressure rod 16, the tea leaves are naturally bent and show a slight degree, and the tea leaves reach 60% dry, and then are transported to the second microwave slow conveying machine through the tea elevator. Machine 8, once again makes the moisture in the ...

Embodiment 2

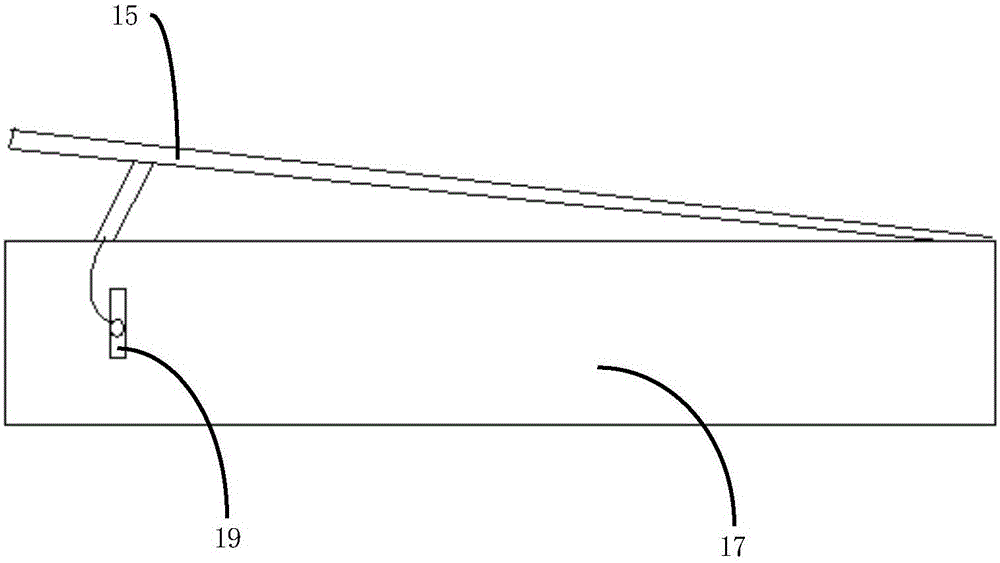

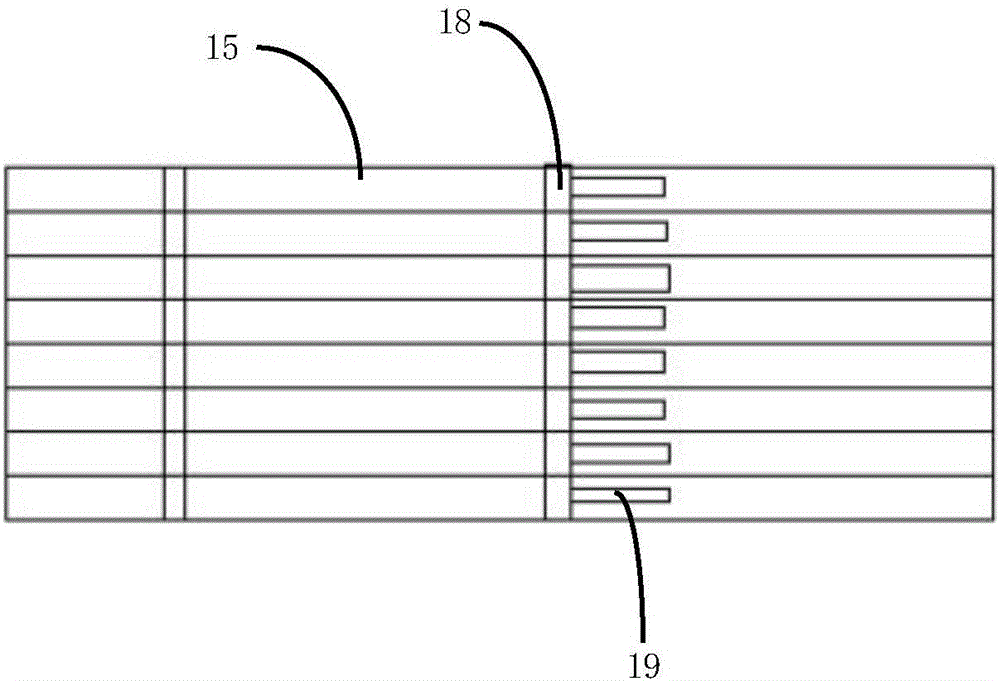

[0025] A sorting machine, comprising a base 17 and striping grooves 15 arranged side by side, the striping grooves 15 are arranged obliquely on the base 17, including 7 to 9 striping grooves arranged side by side, and each stripping groove 15 is provided with at least one Root is used to place the support 18 of pressing bar 16.

[0026] The side of the trimmer is also provided with a rocker 19 for controlling the inclination of the trimmer groove 15 .

[0027] The included angle between the striping groove 15 and the horizontal is not more than 20°.

[0028] A heating device can be arranged at the bottom of each stripping groove 15 .

[0029] With this kind of rafting machine, not only the inclination can be adjusted, but at the same time, the qualified rate of the prepared tea reaches 100%, the leaf bottom is complete, there is no damage to the leaf surface, the taste is particularly fresh, mellow and sweet, and the leaf surface is naturally curved. . Comparative example 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com