Ultrafine wet grinding equipment

A wet grinding and equipment technology, applied in the grinding field, can solve problems such as unsatisfactory grinding effect, achieve the effect of reducing the no-load current and reducing the suspension load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

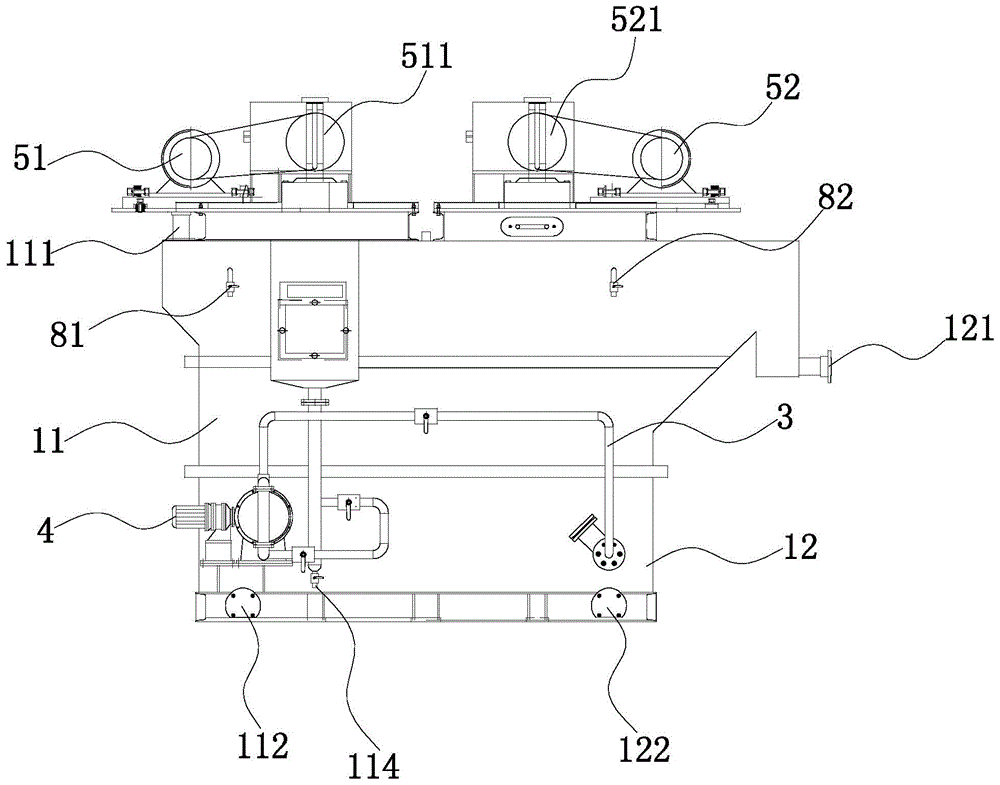

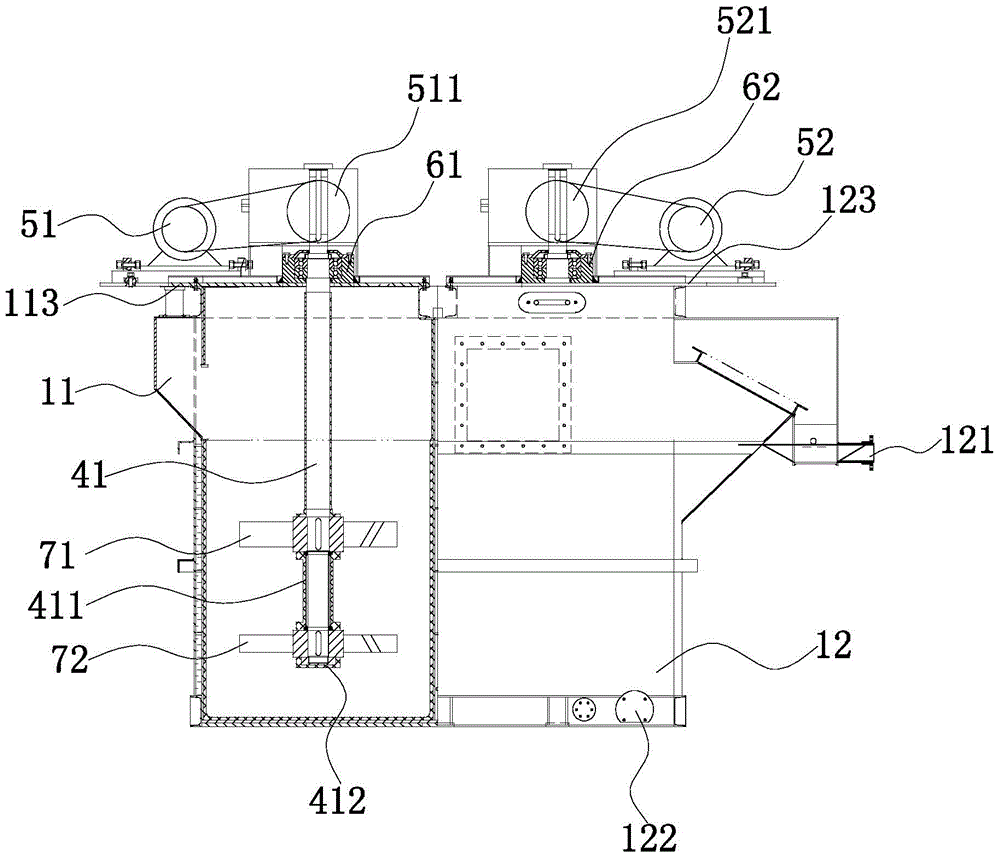

[0026] Such as Figure 1~2 As shown, the present invention discloses an ultrafine wet grinding device, which includes a casing, a first grinding chamber 11 and a second grinding chamber 12 , and the casing covers the outside of the first grinding chamber 11 and the second grinding chamber 12 . The casing is provided with a cooling water inlet 81 and a cooling water outlet 82 . Cooling water enters from the water inlet 81 of the shell and is discharged from the water outlet 82 of the shell. The flow of cooling water takes away the heat of the first grinding chamber 11 and the second grinding chamber 12, which plays a cooling role and protects the second grinding chamber. The wear-resistant rubber on the inner walls of the first grinding chamber 11 and the second grinding chamber 12 prevents the wear-resistant rubber from being deformed and fallen off due to high temperature, and prolongs its service life. The tangential inner wall surfaces of the first grinding chamber 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com