Device for removing fine particulate matter of sintering flue gas by pulse corona charge

A technology of pulse corona and sintering flue gas, applied in the direction of electrostatic separation, electrostatic effect separation, external electrostatic separator, etc., can solve the problems of limited treatment effect of fine particles and difficulty in effectively controlling the emission of fine particles in sintering flue gas, etc., to achieve Improve the efficiency of agglomeration removal, promote the growth of agglomerates, and strengthen the effect of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

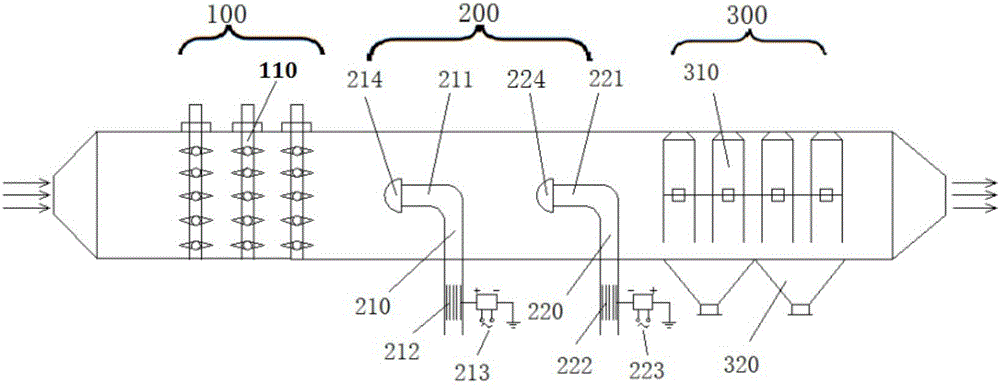

[0037] Such as figure 1 As shown, a device for removing fine particles in iron ore sintering flue gas by pulse corona discharge in this embodiment includes a pulse charging unit 100, an agglomeration unit 200 and a trapping unit 300; and the trapping unit 300 are sequentially arranged in the gas pipeline along the flow direction of the flue gas, wherein the gas pipeline is the removal pipeline 500, the diameter of the removal pipeline 500 is larger than the diameter of the flue gas pipeline 600, and the removal The inlet end of the removal pipe 500 is connected to the flue gas pipe 600 through the expansion pipe 510, and the gas outlet end of the removal pipe 500 is connected to the flue gas pipe 600 through the shrinkage pipe 520, that is, the removal pipe 500 is installed in series on the flue gas pipe 600, The flue gas enters the removal pipe 500 from the expansion pipe 510, and enters the flue gas pipe 600 through the shrinkage pipe 520 after the agglomeration grows. Since...

Embodiment 2

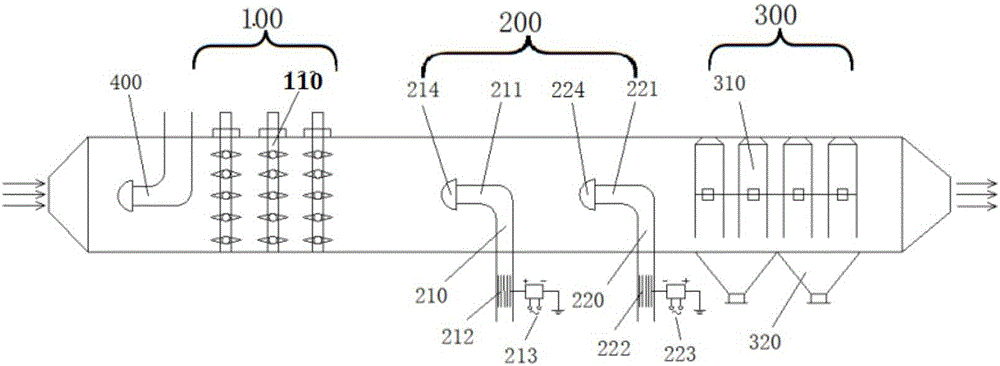

[0048] Such as figure 2 As shown, the basic content of this embodiment is the same as that of Embodiment 1, the difference is that: it also includes a pretreatment unit 400, and the pretreatment unit 400 is used to spray the mist of agglomerating agent or water or salt solution into the flue gas. In this embodiment, water is used, and the particle size of the agglomerating agent or water sprayed into the pretreatment unit 400 is 0.2-3 μm. The pretreatment unit 400 includes a pretreatment nozzle 410, which is used to spray agglomerating agent or water or salt solution droplets into the flue gas, and what is sprayed in this embodiment is: water droplets , The droplet size is 0.2-3μm.

[0049] The emission reduction effect of fine particles using the removal device is as follows, wherein: PM10 emission reduction efficiency (%) is: 47.1%, PM2.5 emission reduction efficiency (%): 34.3%, improving the emission reduction effect of fine particles. Compared with Example 1, PM10 emis...

Embodiment 3

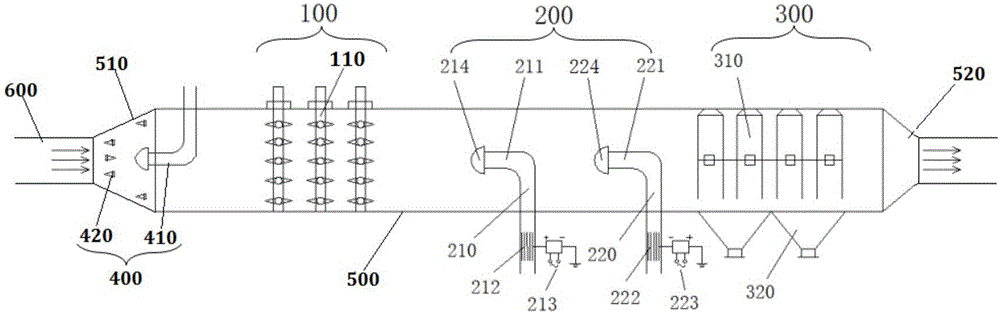

[0053] Such as image 3 with Figure 4 As shown, the basic content of this embodiment is the same as that of Embodiment 2, except that: the pretreatment unit 400 is arranged on the pipeline axis of the expansion tube 510, and the pretreatment unit 400 includes a pretreatment nozzle 410 and a flow guide Components 420, wherein the flow guiding component 420 is arranged on the windward side of the pretreatment nozzle 410, and the flow guiding component 420 is set at the pipe wall edge position of the expansion pipe 510, wherein the flow guiding component 420 includes a first flow guiding block 421 and a second flow guiding block 421 The flow guide block 422, the first flow guide block 421 is arranged on the windward side of the second flow guide block 422, the first flow guide block 421 and the second flow guide block 422 are arranged at the edge of the expansion pipe 510, and the pretreatment nozzle There is no deflector block directly in front of 410, which strengthens the wr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com