Device for restoring soil contaminated by organic arsenic compounds and method for achieving restoration by means of device

A technology for polluted soil and compounds, which is applied to the field of remediation devices for organic arsenic compound-contaminated soils, can solve the problems of short harvesting interval of hyperaccumulator plants, low remediation efficiency of soil remediation devices, and long idle time of polluted soil, etc. Repair efficiency, reduce idle time, and not easy to slide down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for remediating soil contaminated by organic arsenic compounds, comprising the following steps:

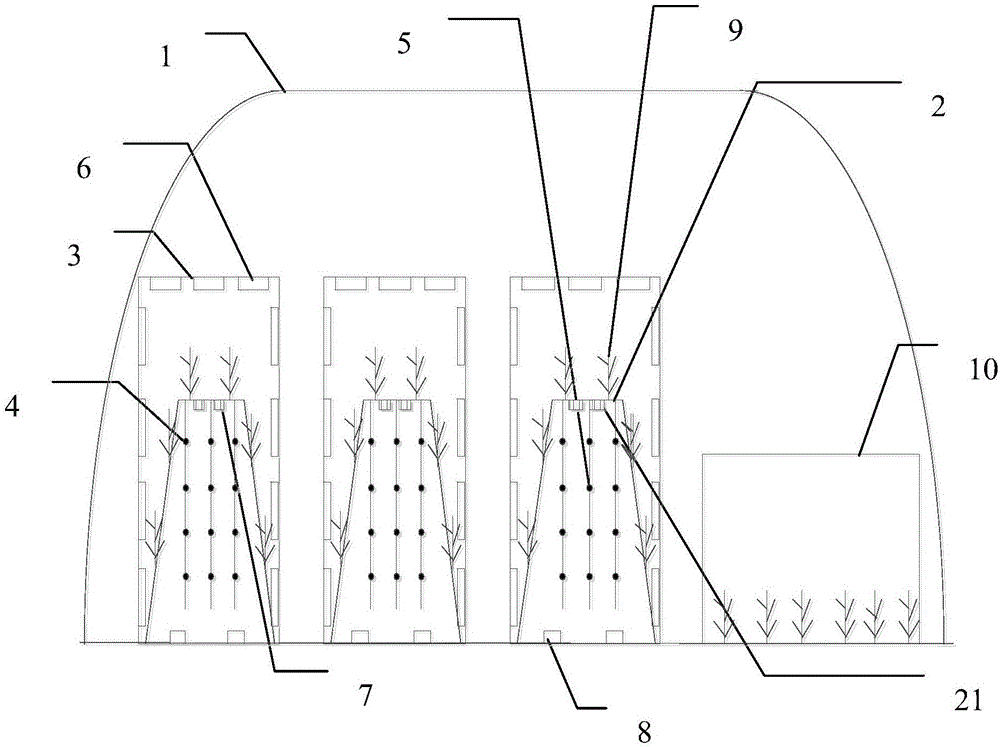

[0044] Excavate the organic arsenic-contaminated soil, transport it to the pre-built centralized treatment shed 1, backfill the excavated soil with new soil, and pile it up into several trapezoids with a small top and a large bottom arranged at an interval of 2m. The height of the trapezoidal soil pile 2 is 2.0m. Each trapezoidal mound outside is provided with a processing cover 3, is provided with several temperature sensors 4 and humidity sensors 5 for monitoring the temperature and humidity in the processing cover in each processing cover; Several microwave repair devices 6 are arranged. The bottom of the concentrated treatment shed is laid with an anti-seepage film layer.

[0045] A number of chemical formulation delivery pipelines 7 and chemical formulation output pipelines 8 respectively extend through the upper and lower parts of the side wall of the proce...

Embodiment 2

[0048] A method for remediating soil contaminated by organic arsenic compounds, comprising the following steps:

[0049] Excavate the organic arsenic-contaminated soil, transport it to the pre-built centralized treatment shed, backfill the excavated soil with new soil, and pile it up into several trapezoids with a small top and a large bottom set at an interval of 2.5m. The height of the trapezoidal soil pile is 1.0 m. Each trapezoidal mound is provided with a processing cover, and each processing cover is provided with several temperature sensors and humidity sensors for monitoring the temperature and humidity in the processing cover; Microwave repair device. The bottom of the concentrated treatment shed is laid with an anti-seepage film layer. A number of chemical formulation delivery pipelines and chemical formulation output pipelines respectively extend through the upper and lower parts of the side wall of the processing hood to the inside of the processing hood, and the...

Embodiment 3

[0053] A method for remediating soil contaminated by organic arsenic compounds, comprising the following steps:

[0054] Excavate the organic arsenic-contaminated soil, transport it to the pre-built centralized treatment shed, backfill the excavated soil with new soil, and pile it up into several trapezoids with a small top and a large bottom set at an interval of 2m. The height of the trapezoidal soil pile is 0.6m . Each trapezoidal mound is provided with a processing cover, and each processing cover is provided with several temperature sensors and humidity sensors for monitoring the temperature and humidity in the processing cover; Microwave repair device. The bottom of the concentrated treatment shed is laid with an anti-seepage film layer.

[0055] A number of chemical formulation delivery pipelines and chemical formulation output pipelines respectively extend through the upper and lower parts of the side wall of the processing hood to the inside of the processing hood, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com