Cutting mechanism

A technology of fixing plates and connecting rods, applied in shearing devices, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting the overall quality of the finished product, easy deformation of the incision, and difficulty in direct cutting of long cylindrical raw materials. Standard cutting surface, saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

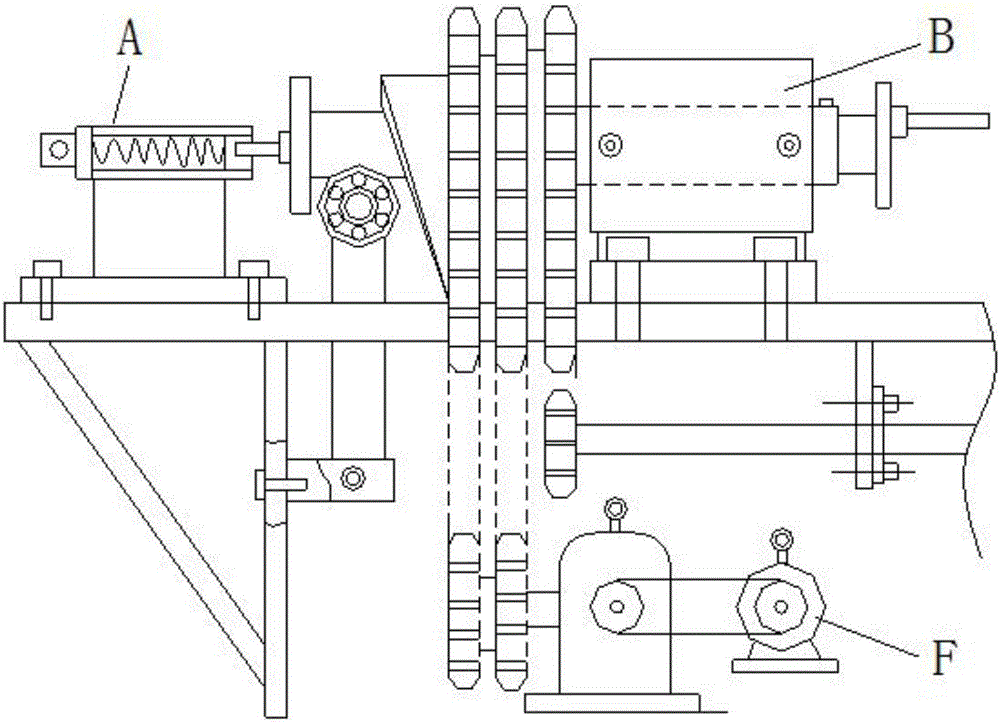

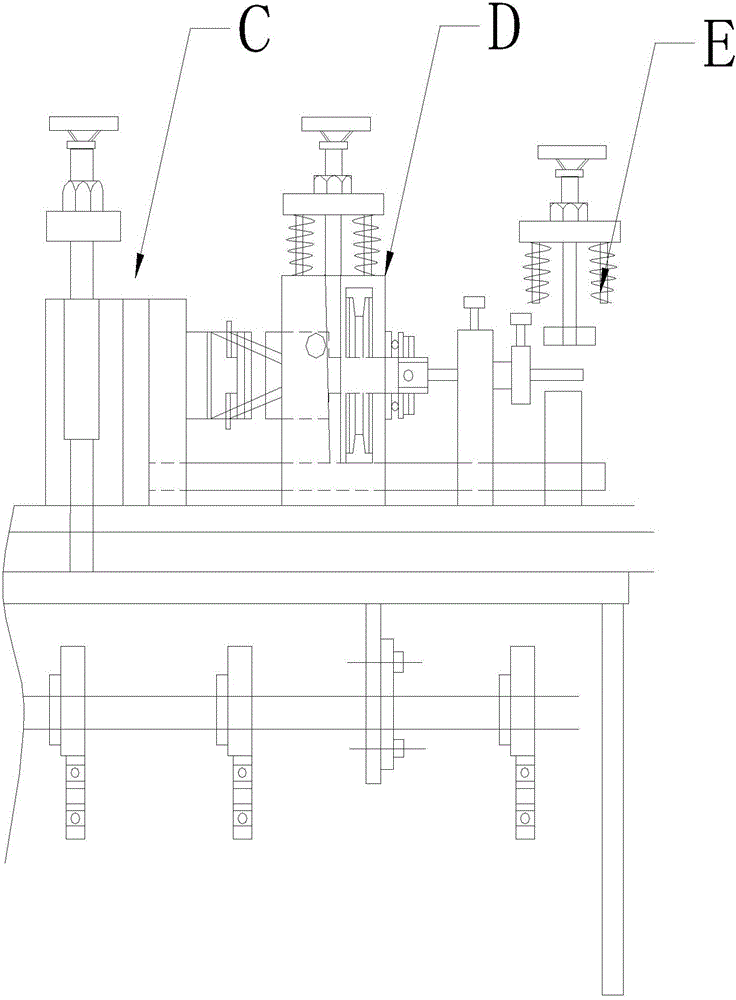

[0013] refer to figure 1 , figure 2 , the overall structure of the elastic cylindrical pin processing device where the present invention is located is that, according to the feeding route, a stretching head pressure support A, a stretching head mechanism B, a compression mechanism C, a material cutting mechanism D, a discharge Mechanism E, wherein the stretching head mechanism B, the pressing mechanism C, the cutting mechanism D, and the unloading mechanism E are respectively connected to the power mechanism F through their own transmission parts.

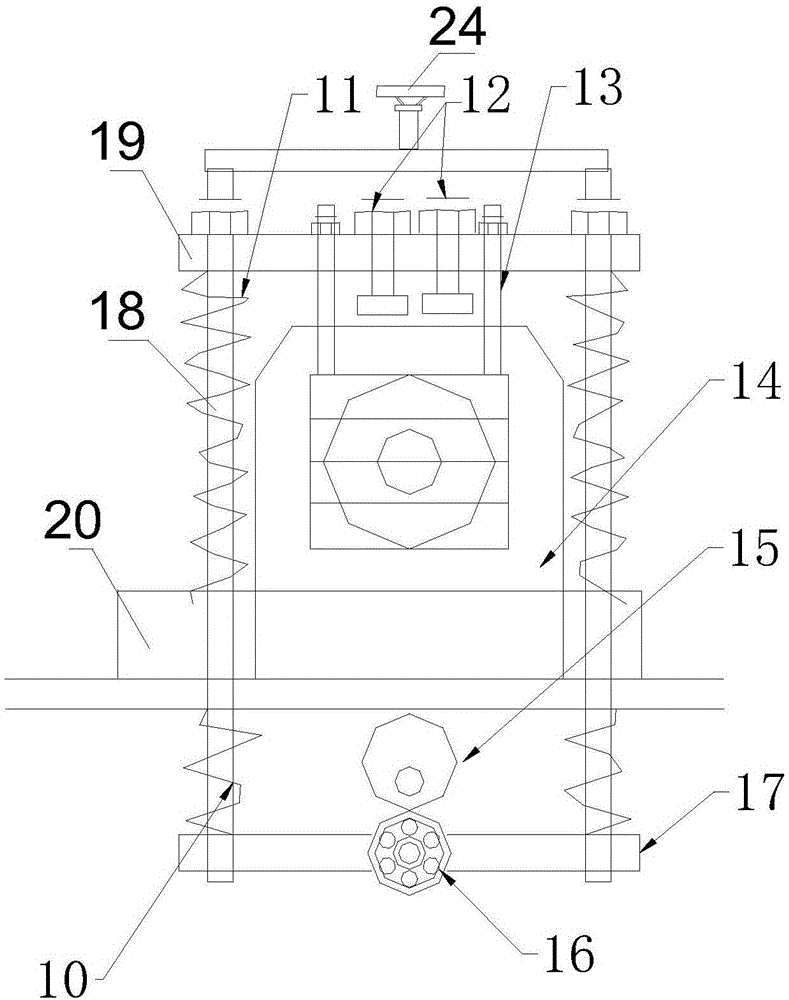

[0014] refer to image 3 , Figure 4 , the structure of the material cutting mechanism D is that a middle fixed plate 20 is fixedly installed on the upper surface of the workbench, a box body 14 is installed on the upper surface of the middle fixed plate 20, and a knife is installed in the horizontal direction of the box body 14 through two groups of bearings-6. The shaft 9 and the cutter shaft 9 are equipped with a planar bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com