Automotive shock absorber set correction device

A technology of automobile shock absorption and correction device, which is applied in the direction of workpiece clamping device and manufacturing tools, which can solve the problems of heavy workload of operators, poor sealing of shock absorber, shortening of spring stroke, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

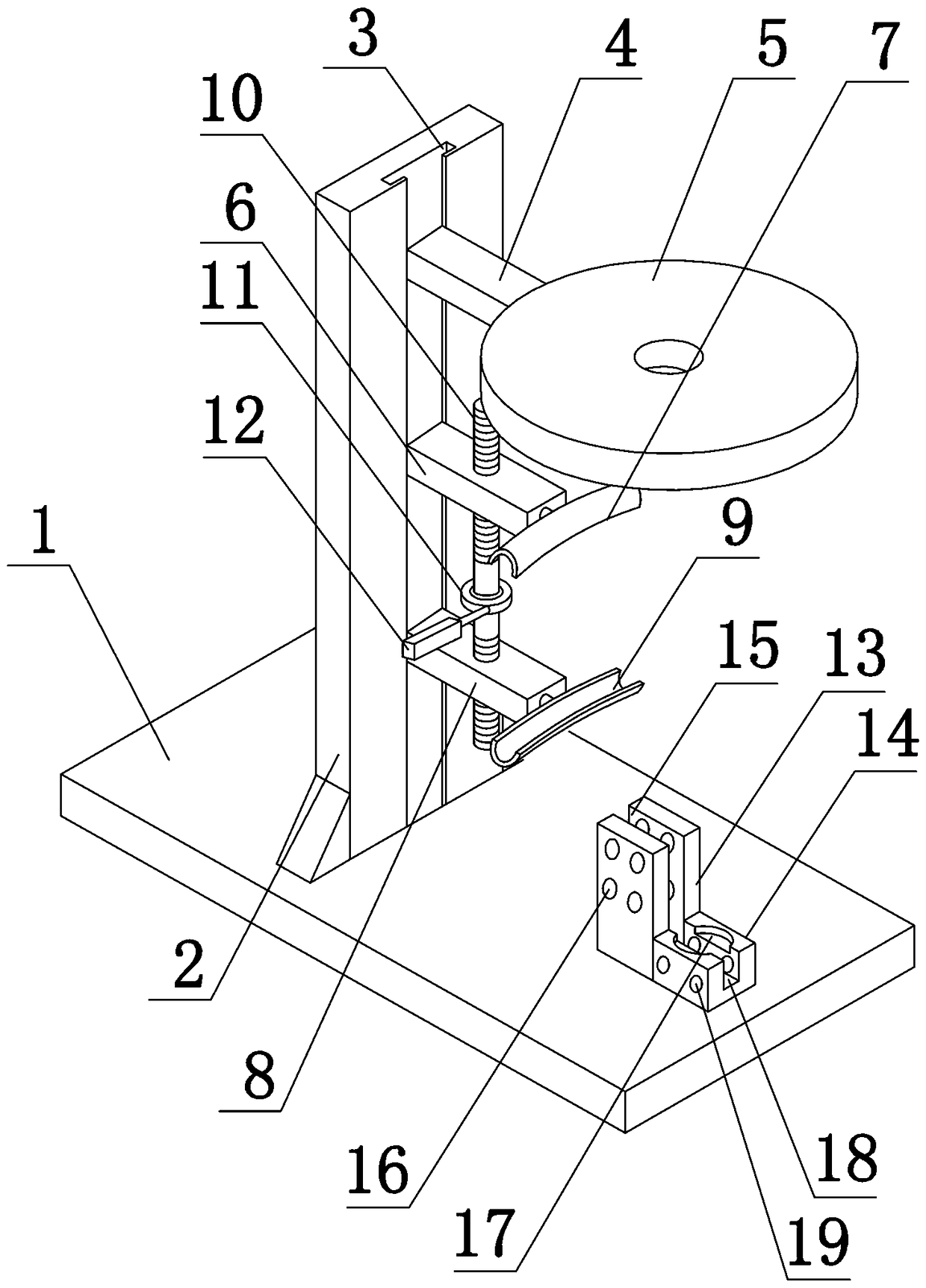

[0028] Such as figure 2 As shown, the present invention discloses an automobile shock absorbing set correction device, comprising a support base 1, the upper end surface of the support base 1 is fixedly connected to the vertical plate 2 and the boss, and the front end surface of the vertical plate 2 is provided with a guide rail 3, and the inside of the guide rail 3 is from top to bottom. The lower slide connects the limit pillar 4, the upper clamp and the lower fixture. The front end of the limit pillar 4 is welded and fixed with a pressure plate 5. The upper clamp includes an upper pillar 6 and an upper clip 7 that is rotatably connected to the front end of the upper pillar 6. The clip 7 can rotate freely, and the lower clamp includes the lower pillar 8 and the lower clip 9 that is rotatably connected to the front end of the lower pillar 8, that is, the lower clip 9 can rotate freely, and the upper clip 7 and the lower clip 9 are curved in the direction of extension. shape,...

Embodiment 2

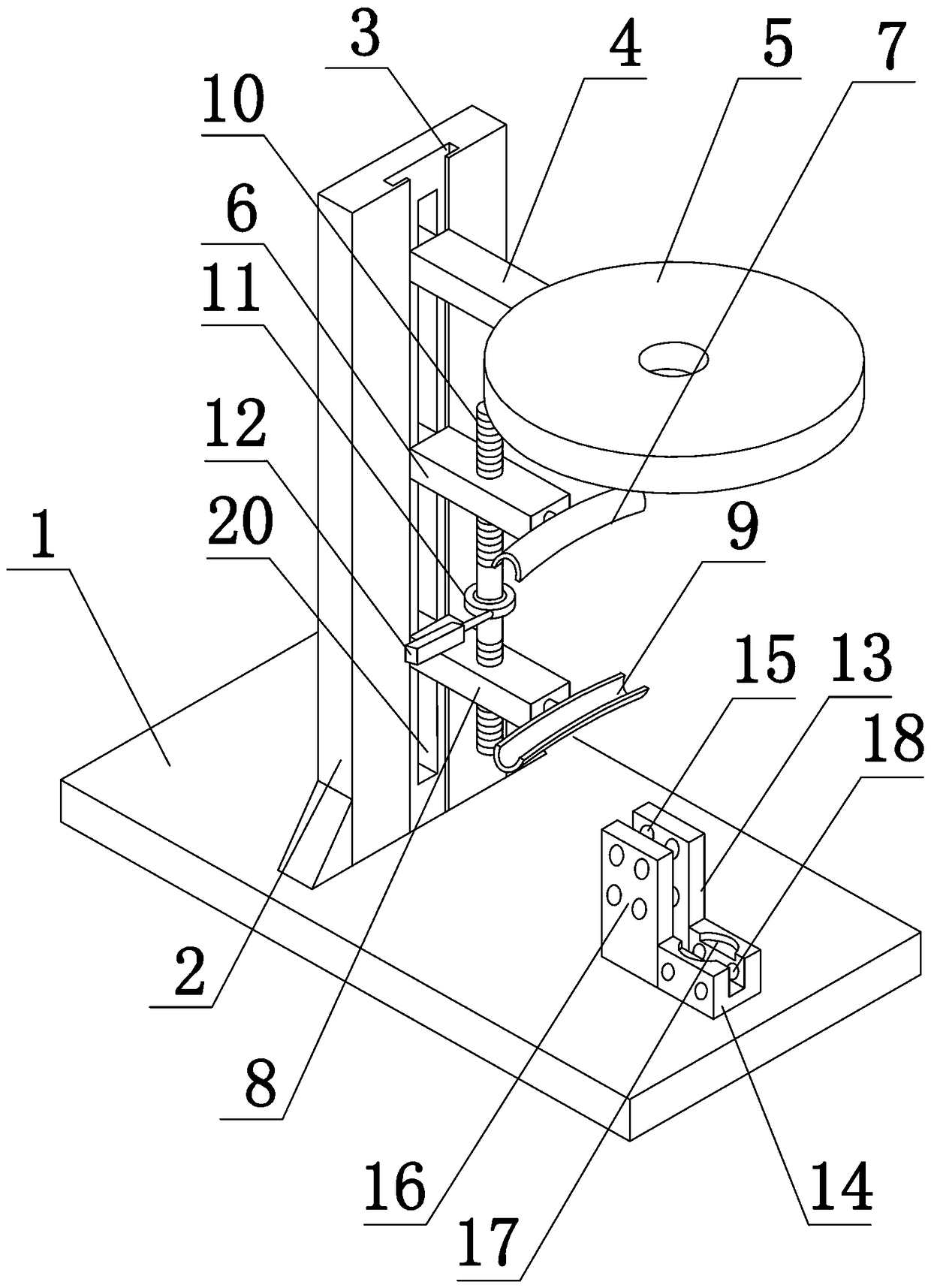

[0030] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 3 to Figure 5 As shown, the bottom of the guide rail 3 is provided with a third through hole 20, the third through hole 20 is an elongated structure, and the rear end faces of the spacer pillar 4, the upper pillar 6 and the lower pillar 8 are all provided with a third threaded hole (not shown in the figure). ), the third threaded hole is internally threaded to connect the second threaded rod 21, the rear end of the second threaded rod 21 passes through the third through hole 20 and a back tightening nut 22 and a fixing nut 23 are installed at its end, the back tightening nut 22 is located on the fixed Between the nut 23 and the vertical plate 2; in addition, a groove 24 is provided on the lower end surface of the pressing plate 5, and a rubber buffer layer 25 is bonded in the groove.

Embodiment 3

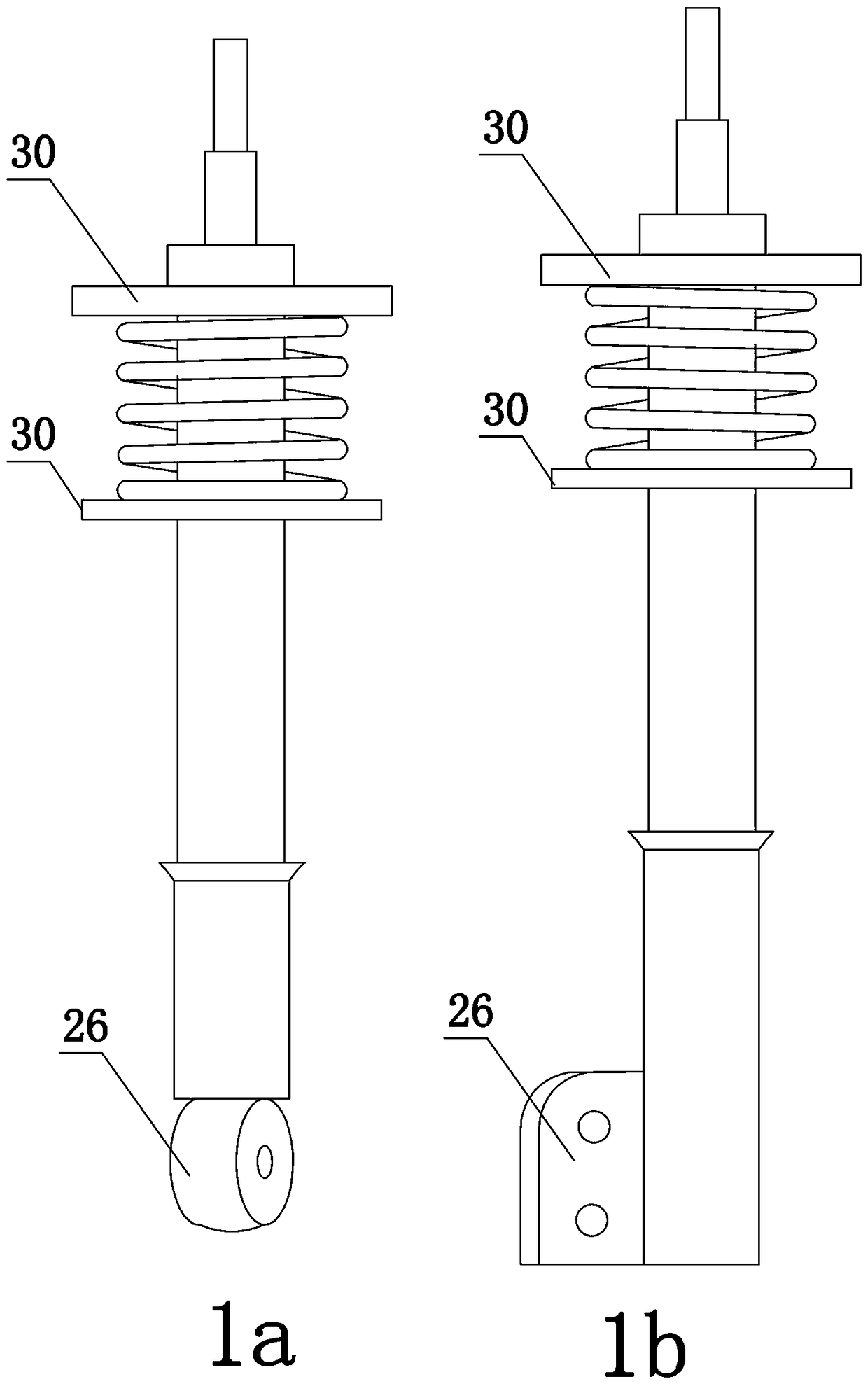

[0032] The structure of this embodiment is basically the same as that of the implementation two, the difference is: as Figure 6 As shown, the edges of the upper clamp 7 and the lower clamp 9 are hinged semi-circular clamps 27, the following clamp 9 is an example, the semi-circular clamp 27 is made of steel and its two ends are respectively hung on the outer wall of the lower clamp 9 Then, when this structure is in use, the spring is further limited by the semi-annular clamp 27, thereby increasing the safety during the calibration process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com