Rapid lifting and pulling forming 3D printing system and printing method thereof

A 3D printing and fast technology, applied in the direction of additive processing, can solve the problem of slow printing speed, and achieve the effect of short printing time, high molding accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

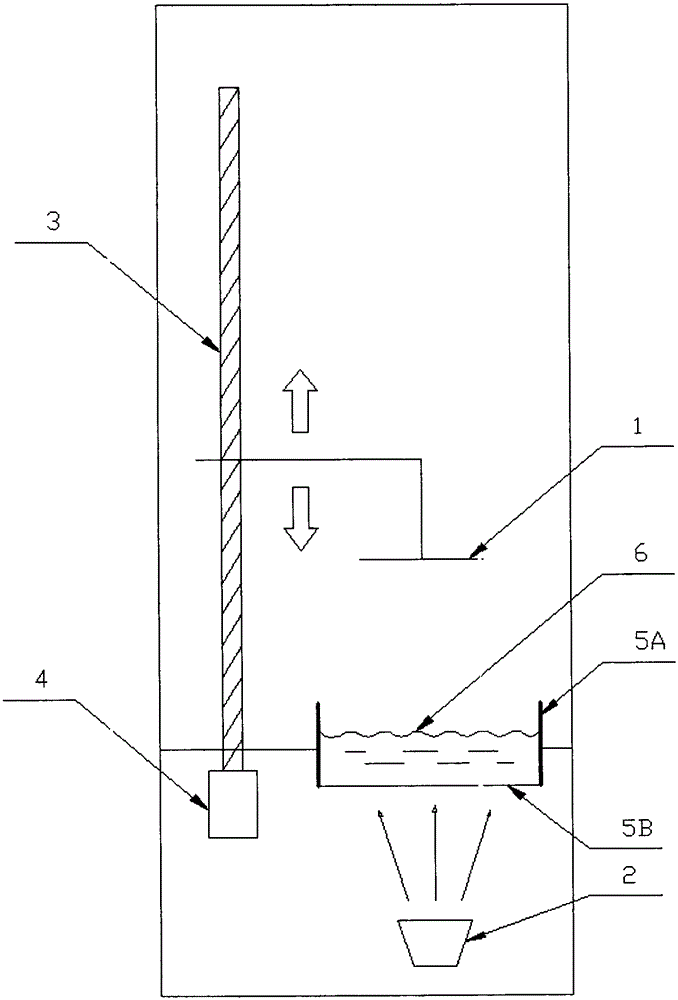

[0031] Such as figure 1 As shown, a rapid pulling forming 3D printing system includes a printing platform 1, a light source system 2, a transmission component 3, a drive host 4, a tank wall 5A of a light-transmitting and oxygen-permeable resin tank system, and a light-transmitting and oxygen-permeable resin tank System tank bottom 5B.

[0032] The light source system is a projection system adopting LCD projection mode.

[0033] The printing lifting platform system is composed of the attached figure 1 The middle printing platform 1, the transmission part 3 and the driving host 4 are composed.

[0034] Attached to the printing lifting platform system figure 1 The medium printing platform 1 is made of aluminum alloy plate.

[0035] Attached to the printing lifting platform system figure 1 The middle transmission part 3 adopts the ball screw system.

[0036] Attached to the printing lifting platform system figure 1 The main engine 4 is driven, and a stepping motor system is...

Embodiment 2

[0045] Such as figure 1 As shown, a rapid pulling forming 3D printing system includes a printing platform 1, a light source system 2, a transmission component 3, a drive host 4, a tank wall 5A of a light-transmitting and oxygen-permeable resin tank system, and a light-transmitting and oxygen-permeable resin tank System tank bottom 5B.

[0046] Further, the light source system is a projection system using a DLP projection method.

[0047] The printing lifting platform system is composed of the attached figure 1 The middle printing platform 1, the transmission part 3 and the driving host 4 are composed.

[0048] Attached to the printing lifting platform system figure 1 The medium printing platform 1 uses polymethyl methacrylate board.

[0049] Attached to the printing lifting platform system figure 1 Middle transmission part 3, selects the screw system for use.

[0050] Attached to the printing lifting platform system figure 1 The main engine 4 is driven in the middle, an...

Embodiment 3

[0059] Such as figure 1 As shown, a rapid pulling forming 3D printing system includes a printing platform 1, a light source system 2, a transmission component 3, a drive host 4, a tank wall 5A of a light-transmitting and oxygen-permeable resin tank system, and a light-transmitting and oxygen-permeable resin tank System tank bottom 5B.

[0060] Further, the light source system is a projection system using LCOS projection.

[0061] The printing lifting platform system is composed of the attached figure 1 The middle printing platform 1, the transmission part 3 and the driving host 4 are composed.

[0062] Attached to the printing lifting platform system figure 1 Middle printing platform 1, select a stainless steel plate with holes.

[0063] Attached to the printing lifting platform system figure 1 The middle transmission part 3 adopts the ball screw system.

[0064] Attached to the printing lifting platform system figure 1 The main engine 4 is driven in the middle, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com