Dust-proof modified plastic, preparation method and application thereof, and dust-proof electric fan blade and dust-proof electric fan

An electric fan, plastic technology, applied in mechanical equipment, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve problems such as lubricant migration and precipitation, and achieve good dustproof effect, good appearance, The effect of reducing the amount of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a second aspect, the present invention provides a method for preparing a dust-proof modified plastic, the method comprising: mixing a matrix resin, an antistatic agent, a slip agent, a lubricant, a nucleating agent and an antioxidant, and then mixing the obtained The mixture is sequentially extruded, drawn, cooled and pelletized.

[0027] In the method of the present invention, for the specific types and amounts of the matrix resin, antistatic agent, slip agent, lubricant, nucleating agent and antioxidant, reference can be made to the corresponding descriptions above, which will not be repeated here.

[0028] In the method of the present invention, the specific methods and conditions of extrusion, drawing, cooling and granulation are not particularly limited, and can be various methods and conditions commonly used in the art, which are well known to those skilled in the art, It is not repeated here.

[0029] In a third aspect, the present invention provides the appl...

Embodiment 1

[0057] This example is used to illustrate the dust-proof modified plastic and its preparation method and the dust-proof electric fan blade of the present invention.

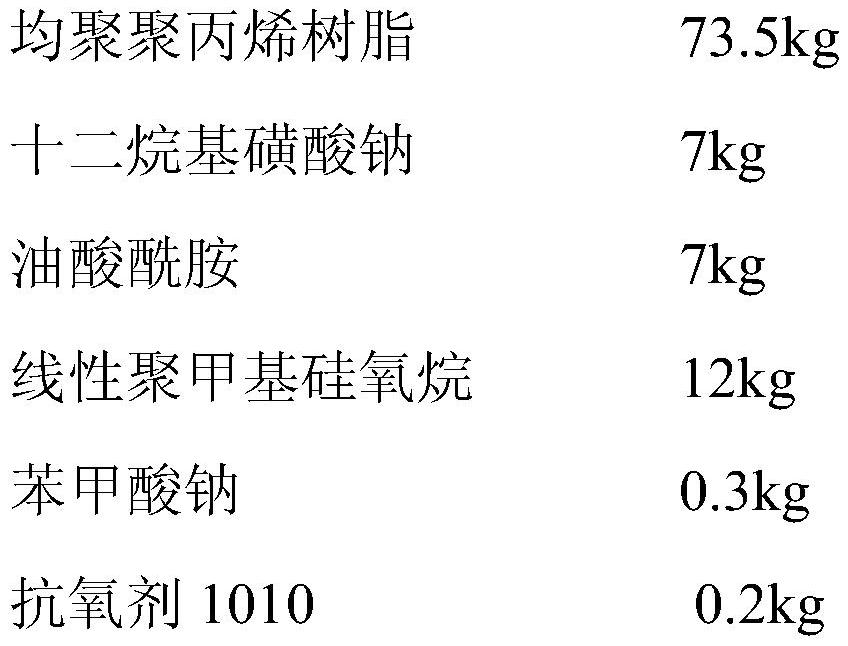

[0058] (1) Accurately weigh each material according to the following proportions:

[0059]

[0060] (2) the above-mentioned materials are placed in a mixer and stirred evenly, then the obtained mixture is sent into a twin-screw extruder, and after being melt-extruded, drawn, cooled and pelletized at 220° C., the dust-proof modification is obtained The plastic particles are then injection-molded to obtain a dust-proof electric fan blade A1.

Embodiment 2

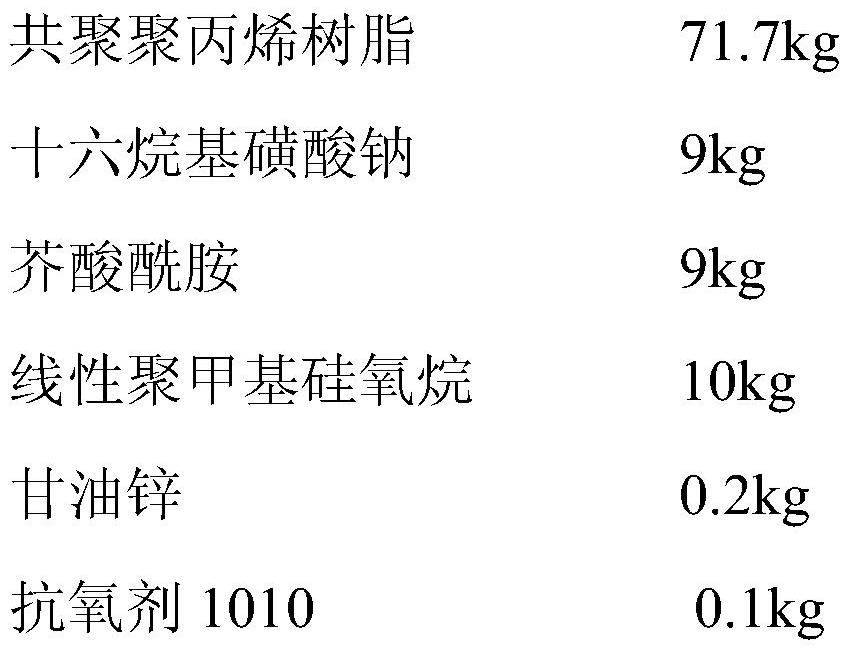

[0062] This example is used to illustrate the dust-proof modified plastic and its preparation method and the dust-proof electric fan blade of the present invention.

[0063] (1) Accurately weigh each material according to the following proportions:

[0064]

[0065] (2) the above-mentioned materials are placed in a mixer and stirred evenly, then the obtained mixture is sent into a twin-screw extruder, and after being melt-extruded, drawn, cooled and pelletized at 240° C., the dust-proof modification is obtained The plastic particles are then injection-molded to obtain a dust-proof electric fan blade A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com