Preparation method of permanent antistatic acrylonitrile-based copolymer and its fiber

An acrylonitrile-based, antistatic technology, used in the manufacture of conductive/antistatic filaments, chemical characteristics of fibers, single-component synthetic polymer rayon, etc., can solve the problems of high price, strong water absorption, and large addition ratio. , to achieve the effect of improving antistatic performance and reducing surface resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

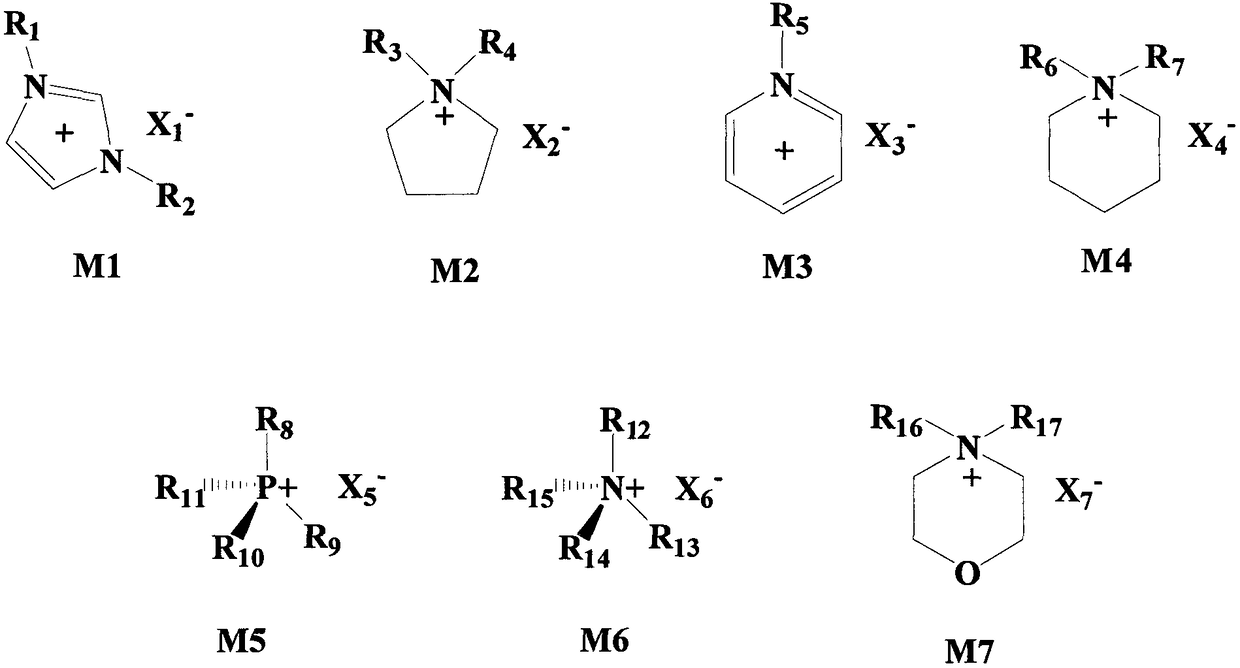

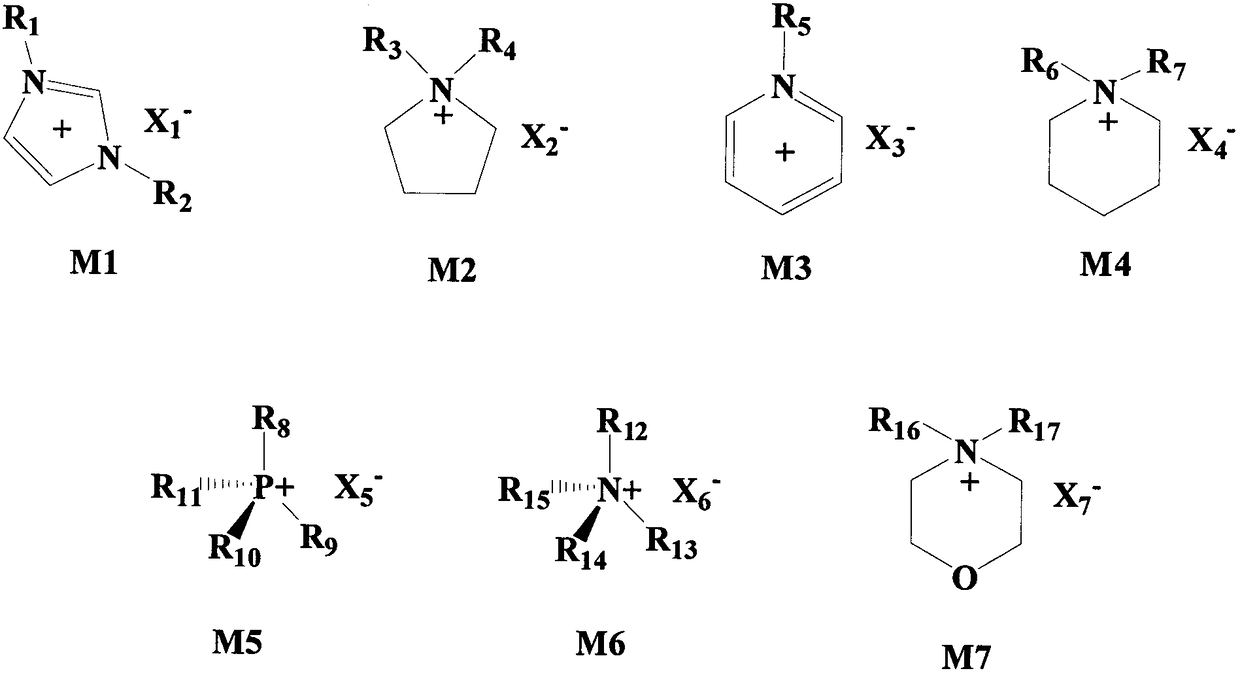

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of permanent antistatic acrylonitrile-based copolymer

[0030] Pour 1 L of dimethylformamide into the reaction kettle, then add 3.75 mol of acrylonitrile monomer, 0.3 mol of methyl acrylate, 0.45 mol of polyethylene glycol methacrylate 400, 0.5 mol of 1-allyl-3 -Butylimidazolium hexafluorophosphate and 0.1mol azobisisobutyronitrile were mixed evenly and then poured into the reaction kettle, heated to 65°C while stirring, reacted for 10 hours after the temperature was constant, and then poured the reaction solution into 5L distilled water Precipitation, standing still, suction filtration, and vacuum drying at 85°C to obtain an acrylonitrile-based copolymer with a melting point of 215°C;

[0031] (2) Preparation of permanent antistatic acrylonitrile-based copolymer fibers

[0032] After mixing 100 parts by mass of acrylonitrile-based copolymers, 0.2 parts by mass of dilauryl thiodipropionate, 0.3 parts by mass of zinc stearate, and 1 part by mass of cellu...

Embodiment 2

[0034] (1) Preparation of permanent antistatic acrylonitrile-based copolymer

[0035] Pour 0.5L dimethylformamide and 0.5L dimethyl sulfoxide into the reaction kettle, then add 3.5mol acrylonitrile monomer, 0.5mol methyl acrylate, 0.5mol polyethylene glycol monomethyl ether methacrylate 400, 0.5mol of 1-allyl-3-butylimidazolium chloride salt and 0.1mol of azobisisobutyronitrile were mixed evenly and then poured into the reaction kettle, heated to 60°C while stirring, and reacted for 10 hours after the temperature was constant , then pour the reaction solution into 7L distilled water for precipitation, let stand, filter with suction, and dry in vacuum at 80°C to obtain an acrylonitrile-based copolymer with a melting point of 188°C;

[0036] (2) Preparation of permanent antistatic acrylonitrile-based copolymer fibers

[0037] 100 parts by mass of acrylonitrile-based copolymers, 0.2 parts by mass of spiroethylene glycol bis[2,2'-methylenebis(4,6-di-tert-butylphenyl)] phosphite, ...

Embodiment 3

[0039] (1) Preparation of permanent antistatic acrylonitrile-based copolymer

[0040] Pour 1L of dimethylformamide into the reaction kettle, and then add 3.75mol of acrylonitrile monomer, 0.5mol of methyl acrylate, 0.25mol of polyethylene glycol acrylate 400, and 0.5mol of 1-allyl-3-butane Mix imidazole tetrafluoroborate and 0.1mol azobisisobutyronitrile evenly and pour it into the reaction kettle, heat up to 65°C while stirring, react for 10 hours after the temperature is constant, then pour the reaction solution into 5L distilled water for precipitation , stand still, filter with suction, and dry under vacuum at 85°C to obtain an acrylonitrile-based copolymer with a melting point of 202°C;

[0041] (2) Preparation of permanent antistatic acrylonitrile-based copolymer fibers

[0042] 100 parts by mass of acrylonitrile-based copolymers, 0.1 parts by mass of spiroethylene glycol bis[2,2'-methylenebis(4,6-di-tert-butylphenyl)] phosphite, 0.2 parts by mass Zinc stearate, 1.2 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com