Hyperbranched ionic liquid/CNFs hybrid particle, microcellular foaming flame-retardant TPV and preparation method thereof

A technology of ionic liquids and hybrid particles, which is applied in the field of microporous flame-retardant TPV and its preparation, can solve the problems of easy damage to the integrity and functionalization of nanoparticles, and complex processes, so as to improve the efficiency of heterogeneous nucleation, Effect of improving cell structure and increasing nucleation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. However, the examples are only used to illustrate and explain the technical solution, and do not constitute a limitation to the solution.

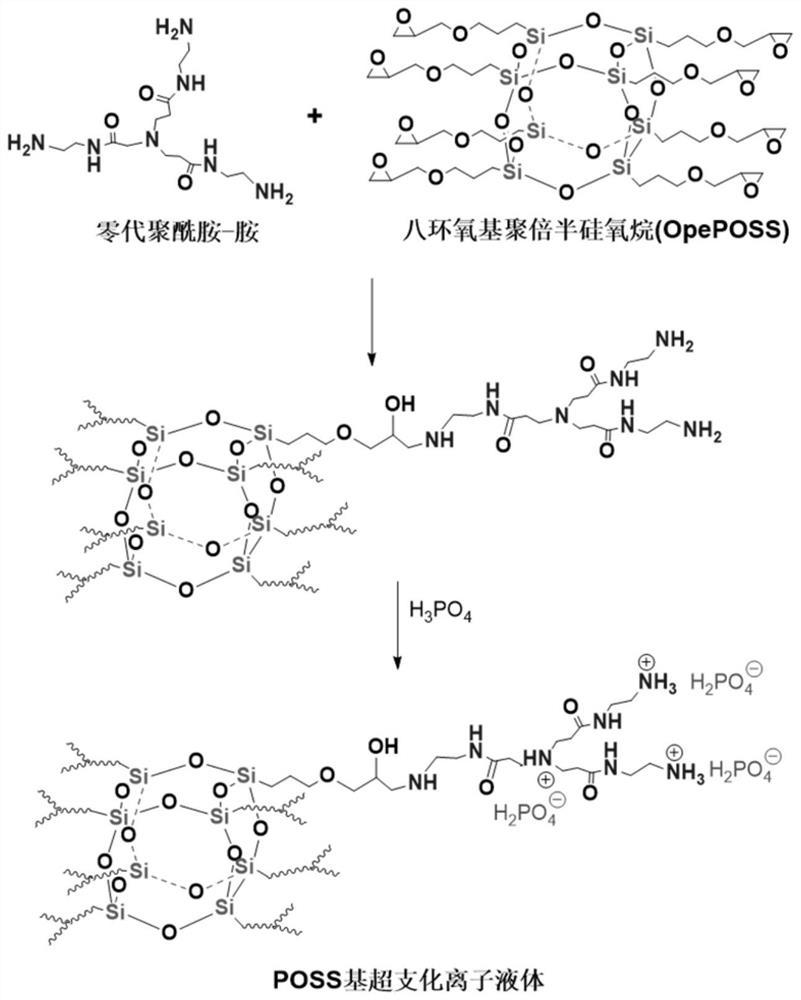

[0029] In this example, the synthesis of POSS-based hyperbranched ionic liquid mainly consists of two steps, as figure 1 Shown:

[0030] The first step is to graft hyperbranched polysilsesquioxane.

[0031] Add 10.0g of OpePOSS to 50ml of methanol and ultrasonically disperse for 0.5h, move it to a three-necked flask, then add 4.0g of zero-generation polyamide-amine and stir to dissolve, heat to 50°C for 8h, and remove the solvent by distillation under reduced pressure to obtain Hyperbranched graft polysilsesquioxane.

[0032] The second step is the preparation of hyperbranched ionic liquids.

[0033] Take 10.0g of hyperbranched grafted polysilsesquioxane and add it into 100mL of deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com