Bite-prevention plastic filled with mace structure powder and preparation method of plastic

A mace and plastic technology, applied in the polymer field, can solve the problems of difficulty in material recycling, inability to prevent damage to the appearance of home appliances, and low production efficiency, so as to reduce the spread of diseases, reduce processing costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

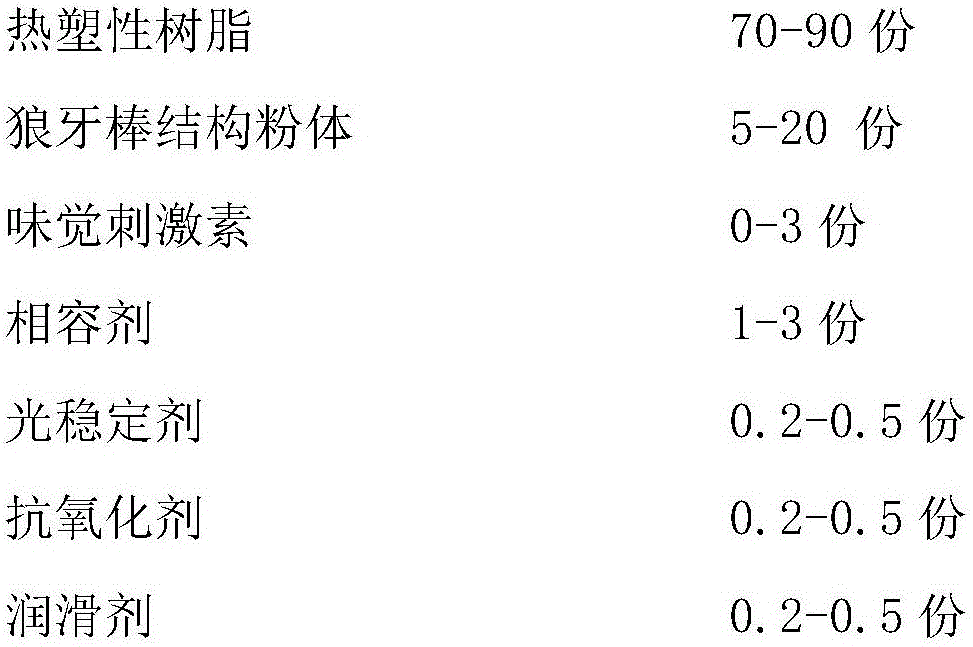

[0030] The raw materials are composed as follows in parts by weight:

[0031]

[0032] The specific preparation method includes the following steps:

[0033] (1) Dry 15 parts of porous diatomaceous earth in an oven at 150°C for 60-80 minutes, and then add 5 parts of ground glass fiber to a high-speed mixer, and pre-mix at high speed for 30 minutes to prepare a mace structure powder;

[0034] (2) Add 20 parts of thermoplastic resin ABS to the mace structure powder in step (1), and then add 3 parts of taste stimulating hormone, and then mix at high speed for 5-10 minutes to prepare a side-feed mixture;

[0035] (3) According to the ratio, the remaining 50 parts of thermoplastic resin ABS, 0.5 part of benzotriazole and hindered amine compound light stabilizer, 0.5 part of hindered phenol and phosphite compound antioxidant and 0.5 part fatty acid Add the amide lubricant to a high-mixer with a temperature of 60-70℃ and protected by nitrogen for 5-10 minutes; then add 3 parts of cyclic anhy...

Embodiment 2

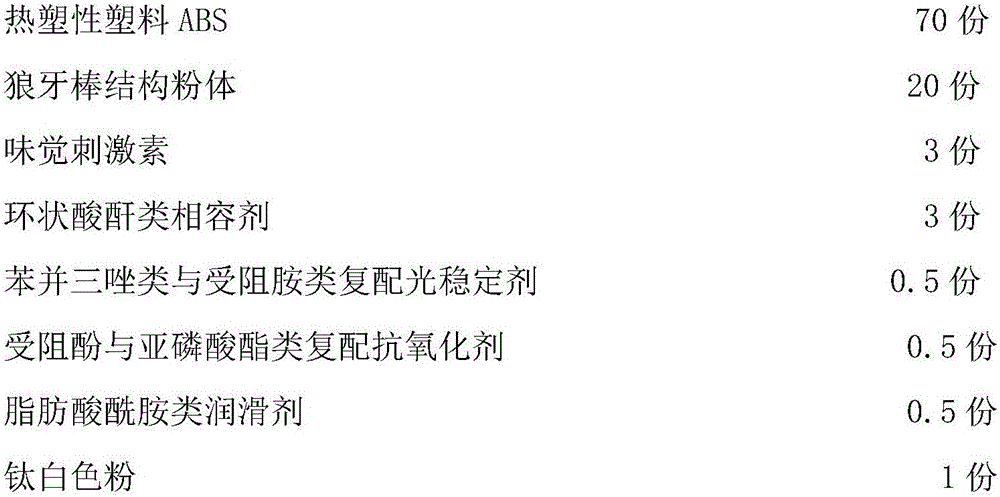

[0038] The anti-biting plastic filled with mace structure powder in this embodiment is composed of the following raw materials in parts by weight:

[0039]

[0040]

[0041] The specific preparation method includes the following steps:

[0042] (1) Dry 9 parts of porous diatomaceous earth in an oven at 150°C for 60-80 minutes, then add 3 parts of ground glass fiber to the high-speed mixer, and pre-mix for 30 minutes at high speed to prepare mace structure powder;

[0043] (2) Add 12 parts of thermoplastic resin ABS to the mace structure powder in step (1), and then add 1 part of taste stimulating hormone, and then mix at high speed for 5-10 minutes to prepare a side-feed mixture;

[0044] (3) According to the ratio, the remaining 71 parts of thermoplastic resin ABS, 0.5 part of benzotriazole and hindered amine compound light stabilizer, 0.5 part of hindered phenol and phosphite compound antioxidant and 0.5 part fatty acid Add the amide lubricant together in a high-mixer with a tempera...

Embodiment 3

[0047] The anti-biting plastic filled with mace structure powder in this embodiment is composed of the following raw materials in parts by weight:

[0048]

[0049]

[0050] The specific preparation method includes the following steps:

[0051] (1) Dry 3.75 parts of porous diatomaceous earth in an oven at 150°C for 60-80 minutes, then add 1.25 parts of ground glass fiber to the high-speed blender, and pre-mix it at high speed for 30 minutes to prepare a mace structure powder;

[0052] (2) Take 5 parts of thermoplastic resin ABS and add it to the mace structure powder in step (1), and then mix at high speed for 5-10 minutes to prepare a side-feed mixture;

[0053] (3) According to the ratio, the remaining 85 parts of thermoplastic resin ABS, 0.5 part of benzotriazole and hindered amine compound light stabilizer, 0.5 part hindered phenol and phosphite compound antioxidant and 0.5 part fatty acid Add the amide lubricant to a high-mixer with a temperature of 60-70℃ and protected by nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com