Well-cementing waterproof gel

A water-blocking and gel technology, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of not blocking water flow and can not use water-blocking effect, etc., and achieves easy pumping, high strength and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention has no special limitation on the preparation method of each cementing hydrogel, and the method of mixing materials well known to those skilled in the art can be used. In the present invention, the preparation method of the cementing water-isolation gel preferably includes the following steps:

[0025] (1) mixing the crosslinking glue with the first part by weight of water to obtain a crosslinking glue solution;

[0026] (2) Mix the cross-linking gel solution in the step (1) with the cross-linking agent and the remaining parts by weight of water, and perform a cross-linking reaction to obtain a cementing water-isolation gel.

[0027] In the present invention, water is preferably added as a solvent in different batches. In the present invention, there is no special limitation on the adding batches of the water, which can be adjusted according to the adding of raw materials. In the present invention, the first weight part of water is preferably 50-9...

Embodiment 1

[0036] Raw materials: 1 part by weight of cross-linking glue; 1 part by weight of cross-linking liquid; 98 parts by weight of water.

[0037] The cross-linking gum is prepared from the following components in mass content: 80% xanthan gum and 20% guar gum.

[0038] The cross-linking liquid is prepared from the following components in mass content: 3% of borax and 97% of water.

[0039] 1) Prepare the cross-linking liquid for use;

[0040] 2) Import a certain amount of water into the reactor, and turn on the stirring;

[0041] 3) Slowly add the cross-linking gel while stirring, and stir for 2-3 hours to fully dissolve the cross-linking gel;

[0042] 4) Add the cross-linking liquid and mix evenly to obtain the cementing water-separating gel.

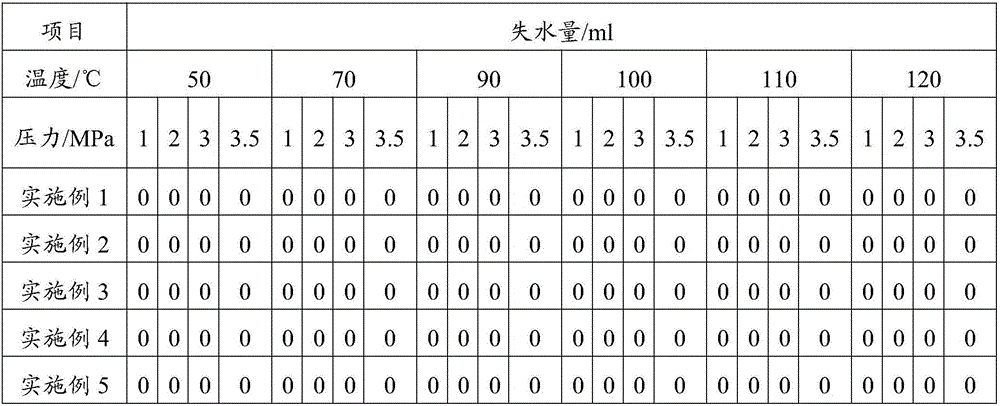

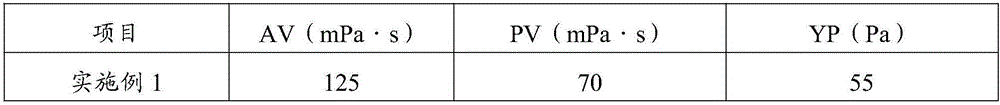

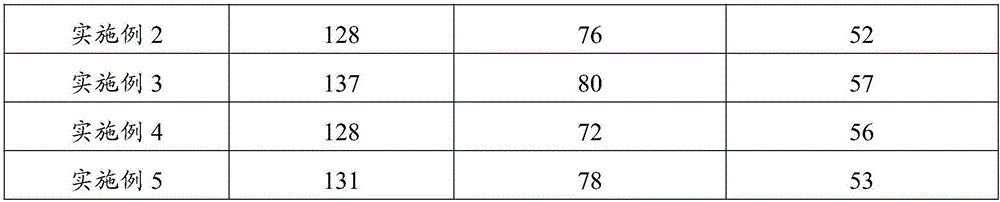

[0043] The performance test of the cementing water-separating gel prepared in this example was carried out according to the following method, and the results obtained are shown in Tables 1-5 respectively.

[0044] Evaluation method of ge...

Embodiment 2

[0050] Raw materials: 1 part by weight of cross-linking glue; 1 part by weight of cross-linking liquid; 97.9 parts by weight of water.

[0051] The cross-linking gum is formulated from the following components: Xanthan gum.

[0052] The cross-linking solution is prepared from the following components in mass content: 5% of borax and 95% of water.

[0053] According to the method of Example 1, the well cementing water-separating gel was prepared.

[0054] The performance test of the cementing water-separating gel prepared in this example was carried out according to the method described in Example 1, and the results obtained are shown in Tables 1-5 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com