A kind of method for extracting and separating atmospheric pressure heavy oil vacuum residue

A technology for atmospheric pressure heavy oil and vacuum residue oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, refined hydrocarbon oil, etc. High degree of removal, cheap and environmentally friendly solvent, effect of improving extraction rate and degree of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

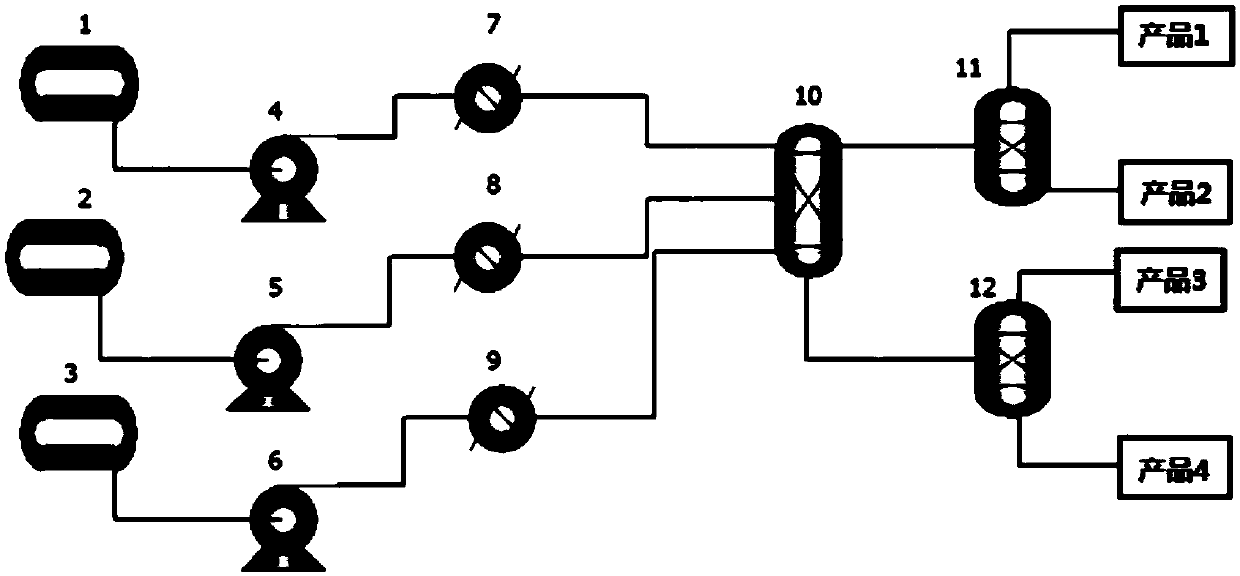

[0037] This embodiment provides a method for extracting and separating heavy oil, which is carried out by using an extraction tower. The specific process is as follows figure 1 shown. The method includes the following steps:

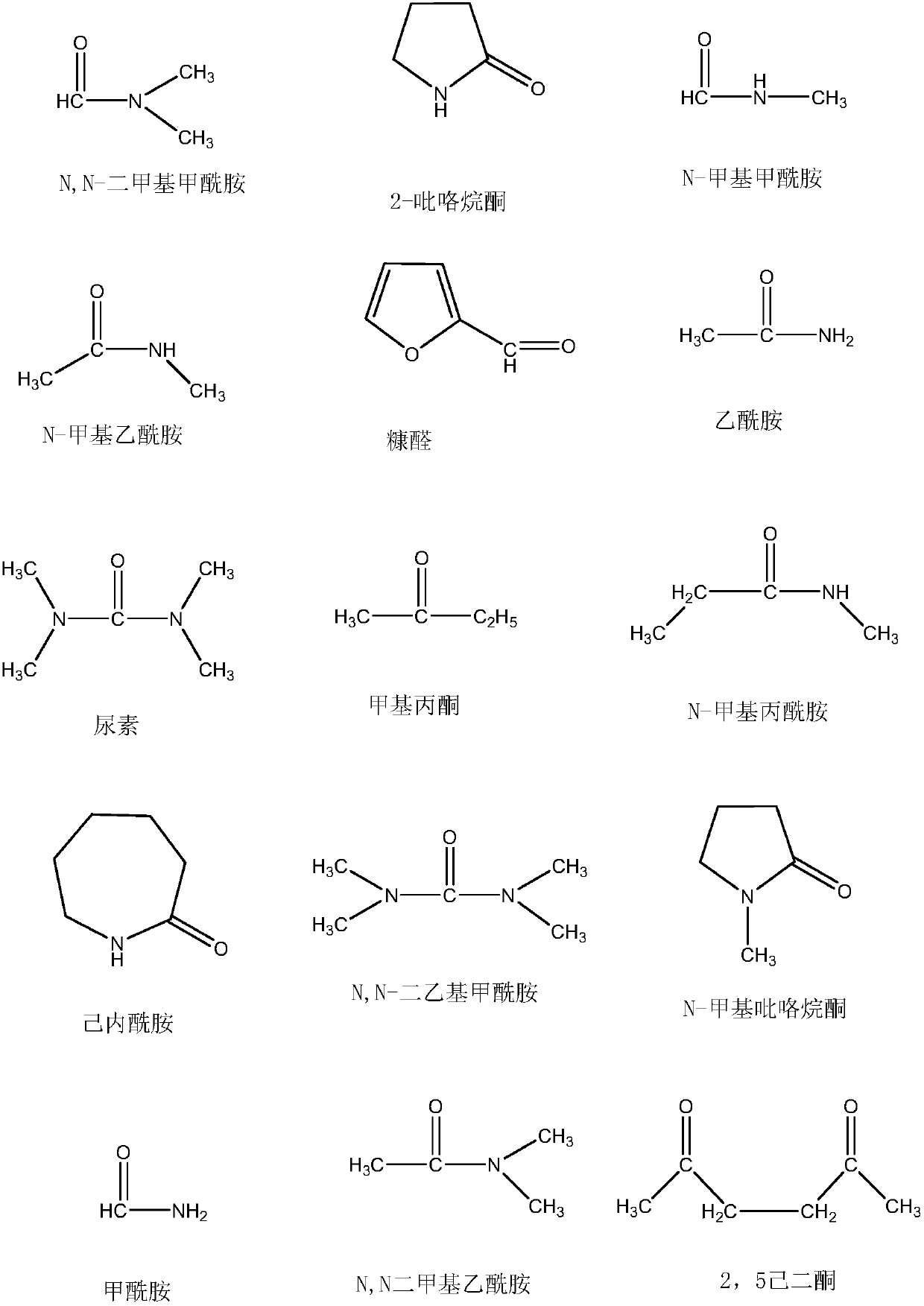

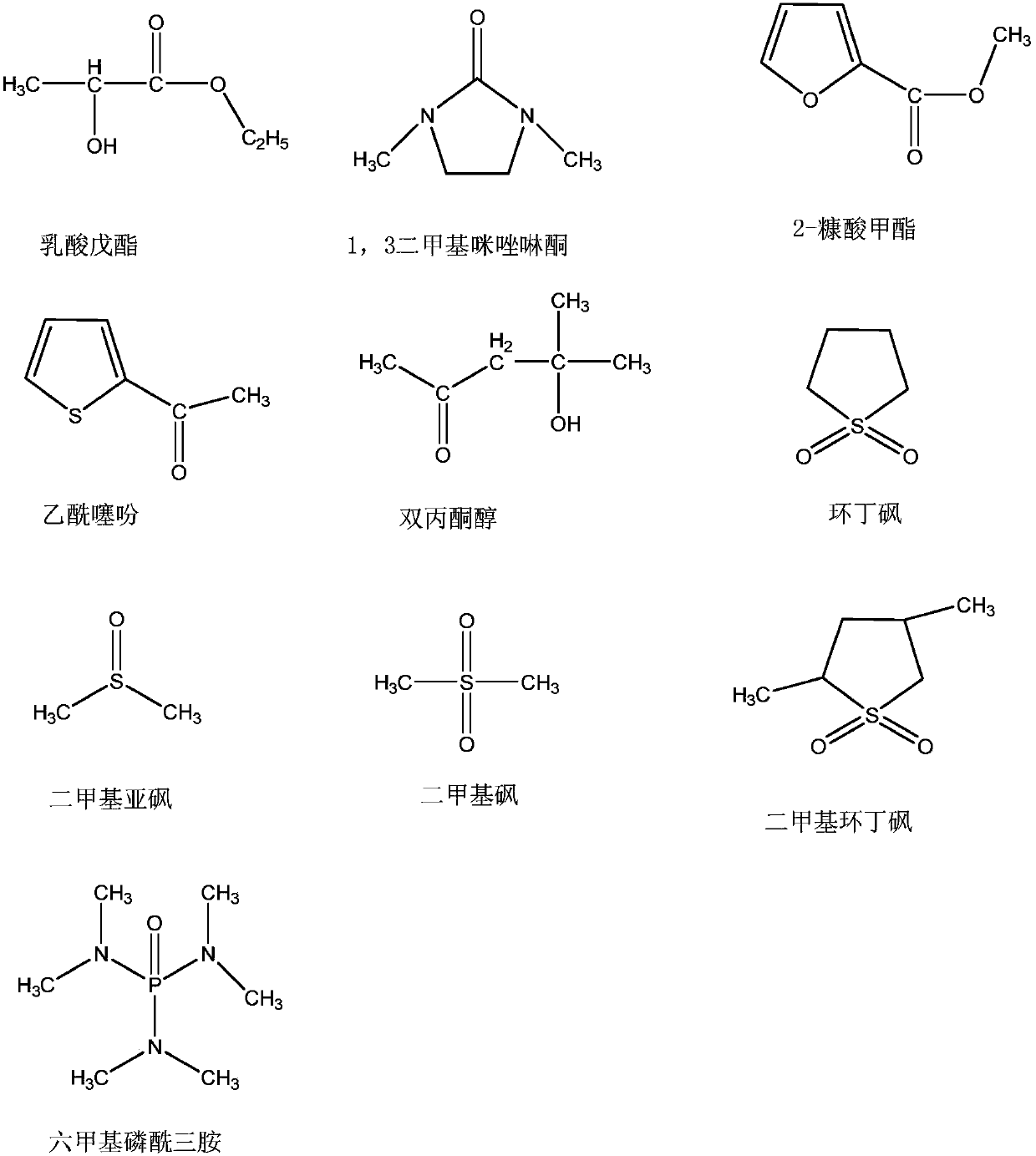

[0038] Use dimethyl sulfoxide as solvent 1, let it enter the upper part of the extraction tower, the viscosity reducer enters the middle part of the extraction tower, heavy oil 1 enters the lower part of the extraction tower, the solvent-oil mass ratio is 3:1, the temperature is 70 °C, the pressure 1 MPa, heavy oil 1, polar solvent 1, and viscosity reducer are in countercurrent contact in the tower; the deasphalted oil phase is discharged from the top of the extraction tower, mainly containing saturated hydrocarbons and light aromatics, and enters the solvent evaporator; the bottom of the extraction tower is discharged The deoiled bituminous phase, mainly containing condensed ring aromatics, colloids and asphaltenes, enters the solvent evaporator.

[0...

Embodiment 2

[0049] This embodiment provides a method for extracting and separating heavy oil, which is carried out by using an extraction tower. The specific process is as follows figure 1 shown. The method includes the following steps:

[0050] Using sulfolane as the solvent 2, it enters the upper part of the extraction tower, the viscosity reducer enters the middle part of the extraction tower, and the heavy oil 2 enters the lower part of the extraction tower, the solvent-oil mass ratio is 3:1, the temperature is 75°C, and the pressure is 1.2MPa The heavy oil 2 is in countercurrent contact with the polar solvent 2 and the viscosity reducer in the tower; the deasphalted oil phase discharged from the top of the extraction tower mainly contains saturated hydrocarbons and light aromatics, and enters the solvent evaporator; the deoiled oil phase discharged from the bottom of the extraction tower Asphalt phase, mainly containing polycyclic aromatic hydrocarbons, colloids and asphaltenes, ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com