Converter bearing electric heating oil bath assembly method

An assembly method and bearing technology, which is applied in the manufacture of converters, etc., can solve the problems of uneven temperature and uneven heating, and achieve the effect of low site requirements, uniform heating, and low assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The electric heating oil bath assembly method of the converter bearing proposed by the present invention includes three major processes of construction preparation, heating, hoisting and attachment installation;

[0028] Specifically include the following steps:

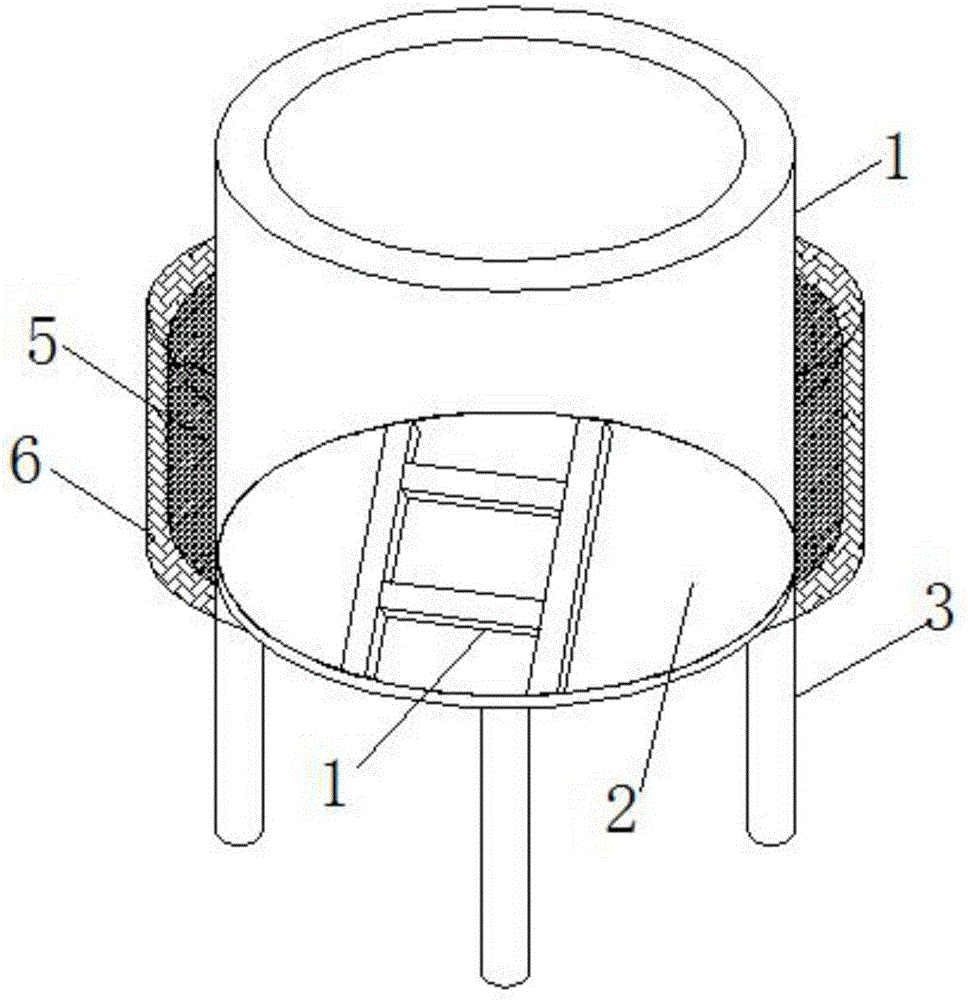

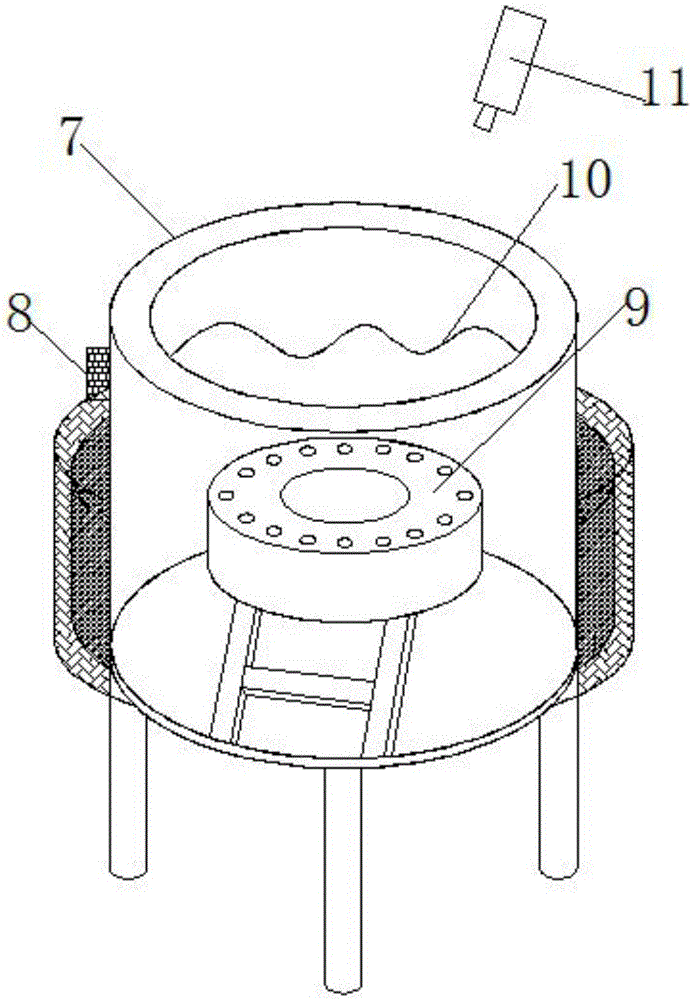

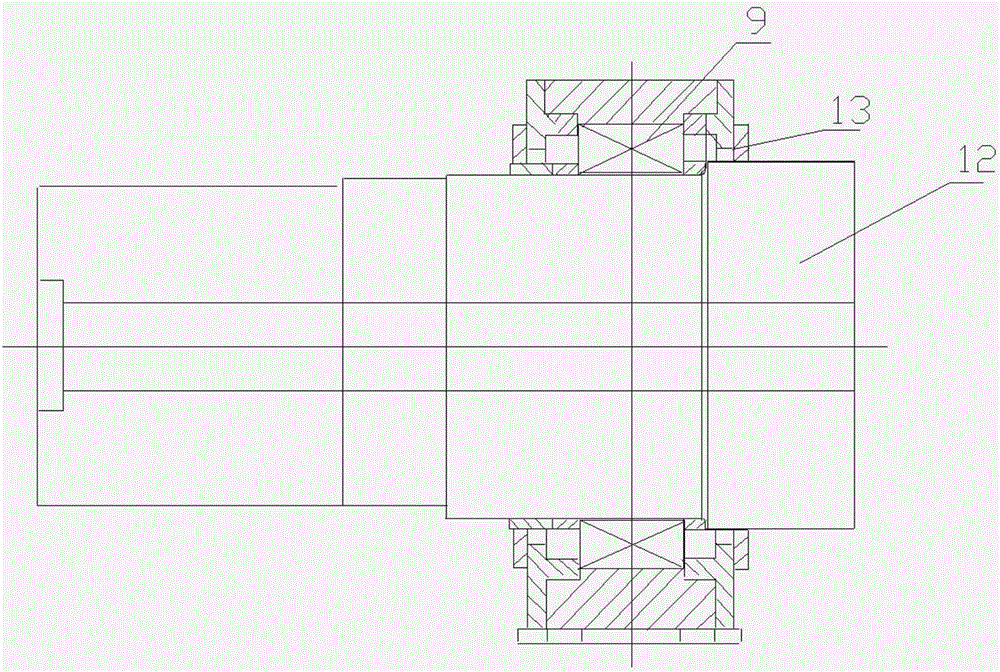

[0029] S1. Make the heating container 7. The heating container 7 is composed of the container wall 1, the container bottom 2, the container leg 3, the bottom plate reinforcement rib 4, the heating sheet 5 and the thermal insulation cotton 6. The container wall 1 is made of a steel plate with a thickness of δ12mm. A round pipe with a diameter of φ2000mm and a height of 1m; the bottom 2 of the container is welded and connected with the steel plate with a thickness of δ12mm and the wall 1 of the container; the leg 3 of the container is made of H350 steel, and the height is 200mm; the reinforcement rib 4 of the bottom plate is made of 16# channel steel It is formed by spot welding with the bottom 2 of the containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com