A kind of preparation method of foamed aluminum material

A technology of foamed aluminum and aluminum chips, which is applied in the field of foamed aluminum materials, can solve problems such as unsatisfactory fluid uniform distribution, and achieve the effects of low production cost, improved strength, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

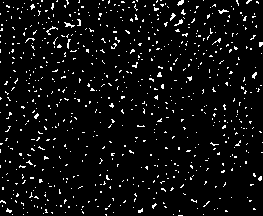

Image

Examples

Embodiment 1

[0027] A preparation method of foamed aluminum material, the method specifically comprises the following steps:

[0028] Step 1, putting aluminum chips and ammonium chloride into a stirred tank, and then stirring and blending in a water bath for 2 hours;

[0029] Step 2, adding epoxy resin to absolute ethanol, stirring evenly until completely dissolved;

[0030] Step 3, add the dispersant to the solution in step 2, stir evenly until completely dissolved, then slowly add the mixture in step 1 dropwise, stir evenly to form a viscous suspension;

[0031] Step 4, pour the suspension viscous liquid into the mold for low-temperature curing for 1 hour, and then perform high-pressure pressing to form a block;

[0032] Step 5, put the block into the reaction kettle for high-temperature sealing and sintering 3, then carry out gradient decompression sintering for 6 hours, and obtain the foamed aluminum material after natural cooling.

[0033] The formula in the preparation method is as...

Embodiment 2

[0042] A preparation method of foamed aluminum material, the method specifically comprises the following steps:

[0043] Step 1, putting aluminum chips and ammonium chloride into a stirred tank, and then stirring and blending in a water bath for 3 hours;

[0044] Step 2, adding epoxy resin to absolute ethanol, stirring evenly until completely dissolved;

[0045] Step 3, add the dispersant to the solution in step 2, stir evenly until completely dissolved, then slowly add the mixture in step 1 dropwise, stir evenly to form a viscous suspension;

[0046] Step 4, pour the suspension viscous liquid into the mold for low-temperature curing for 2 hours, and then perform high-pressure pressing to form a block;

[0047] Step 5, put the block into the reaction kettle for high-temperature sealing and sintering for 8 hours, then carry out gradient decompression sintering for 15 hours, and obtain the foamed aluminum material after natural cooling.

[0048] The formula in the preparation ...

Embodiment 3

[0057] A preparation method of foamed aluminum material, the method specifically comprises the following steps:

[0058] Step 1, putting aluminum chips and ammonium chloride into a stirred tank, and then stirring and blending in a water bath for 3 hours;

[0059] Step 2, adding epoxy resin to absolute ethanol, stirring evenly until completely dissolved;

[0060] Step 3, add the dispersant to the solution in step 2, stir evenly until completely dissolved, then slowly add the mixture in step 1 dropwise, stir evenly to form a viscous suspension;

[0061] Step 4, pour the suspension viscous liquid into the mold for low-temperature curing for 2 hours, and then perform high-pressure pressing to form a block;

[0062] Step 5, put the block into the reaction kettle for high-temperature sealing and sintering for 6 hours, then carry out gradient decompression sintering for 12 hours, and obtain the foamed aluminum material after natural cooling.

[0063] The formula in the preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com