Device and method for fixing and secondary deviation correction of pre-embedded steel column in underground diaphragm wall

An underground diaphragm wall and deviation correction device technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as low construction accuracy, high construction cost, and difficulty in deviation correction, and achieve simple construction operations, improved construction efficiency, and improved The effect of placement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings and embodiments.

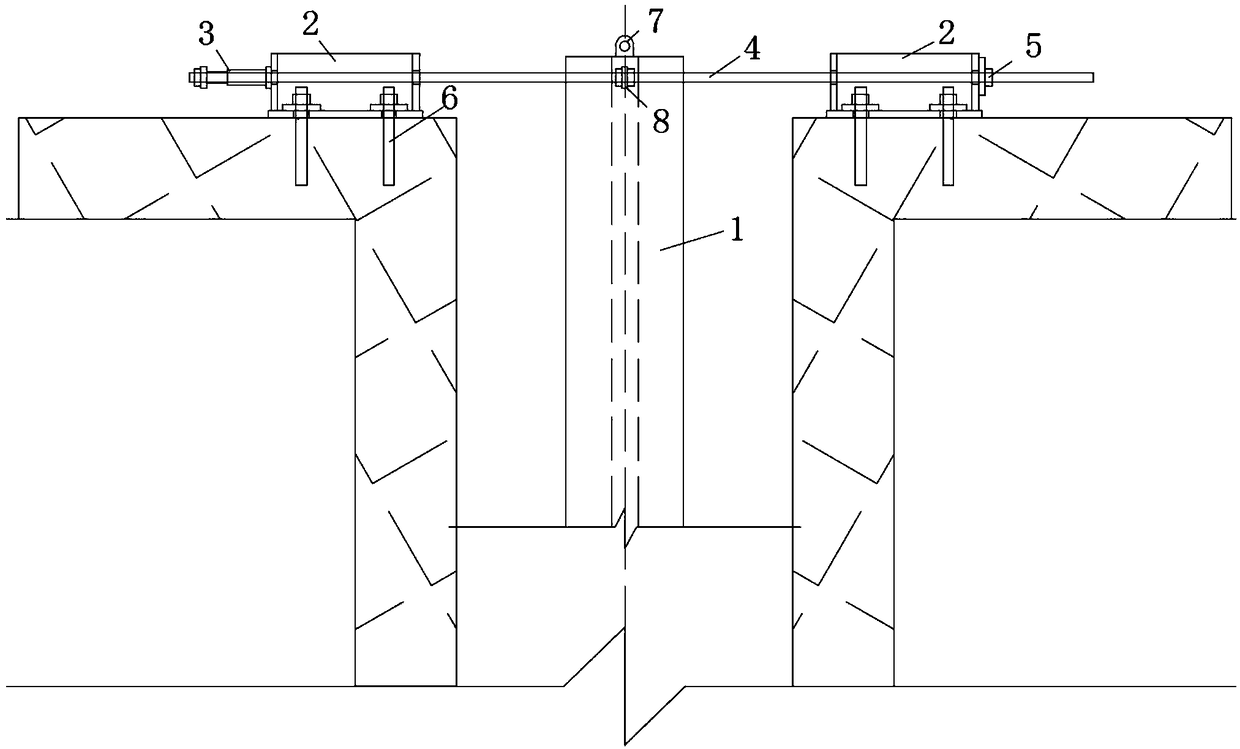

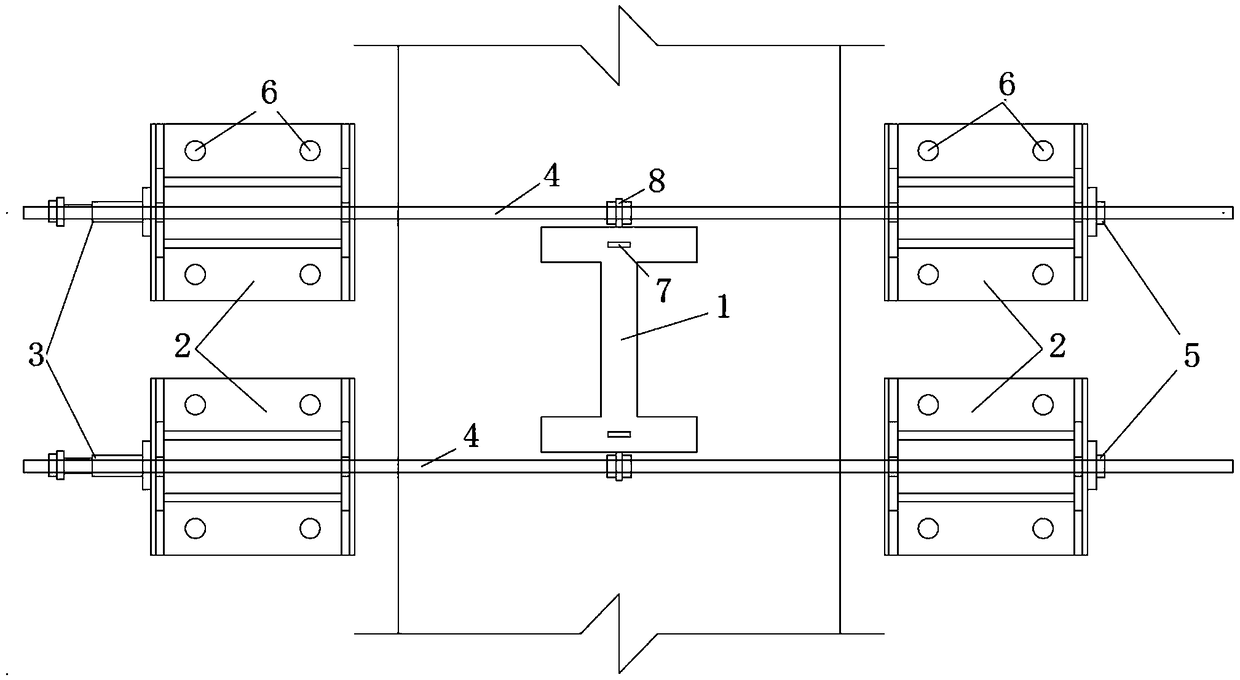

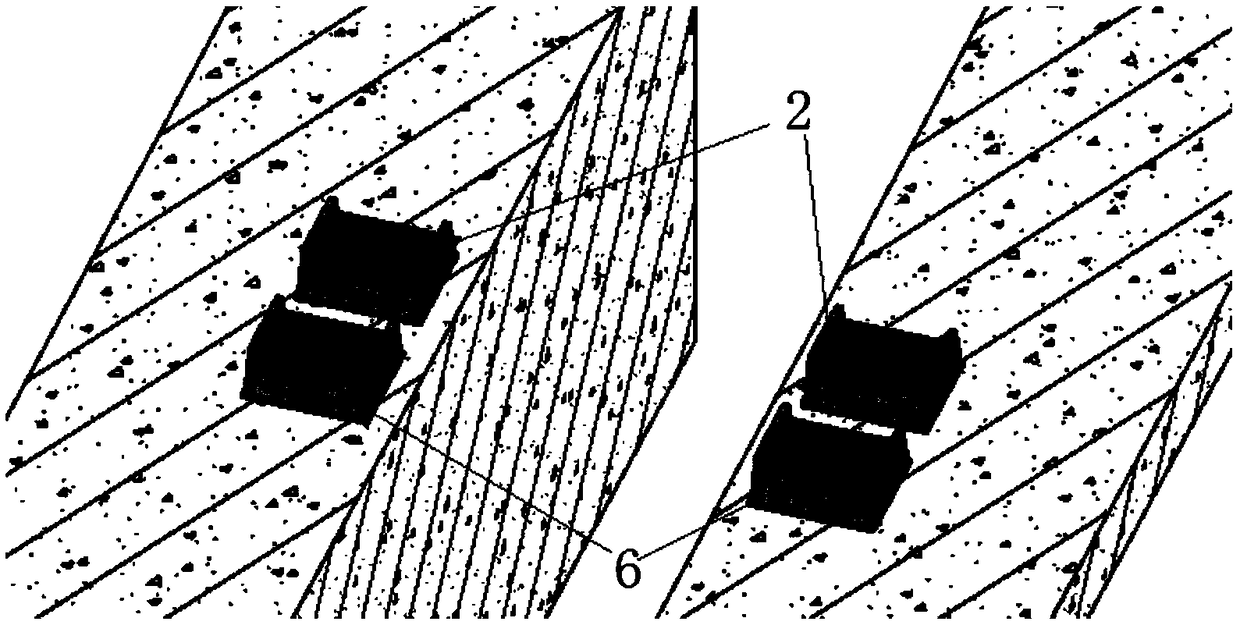

[0031] Such as figure 1 , As shown in 2, an underground continuous wall embedded steel column fixing and secondary correction device, including a steel base 2, embedded bolts 6, finishing rolled rebar 4, jacks 3, nut pads 5. The steel base 2 is fixed on both sides of the guide wall by the embedded bolts 6, the four steel bases 2 are fixed and connected to the steel column 1 by two fine-rolled rebars 4, and the steel base 2 and the fine-rolled rebar 4 pass through matching The nut backing plate 5 is fixed, and one end of the finishing rolled rebar 4 is connected with a jack 3. When the correction steel column 1 is displaced, loosen the nut backing plate 5, and use the jack 3 to make the finishing rolled rebar 4 symmetrical, pre-tightened and tensioned Rolled rebar 4 completes the correction of profile steel column 1. The profiled steel column 1 and the finish-rolled re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com