Self-heating solid wood composite floor and preparation method thereof

A solid wood composite floor, self-heating technology, applied in the field of floor heating floor manufacturing, can solve the problems of surface cracking, high maintenance or replacement cost, power failure of the floor system, etc. Solve the effect of local blackening or burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

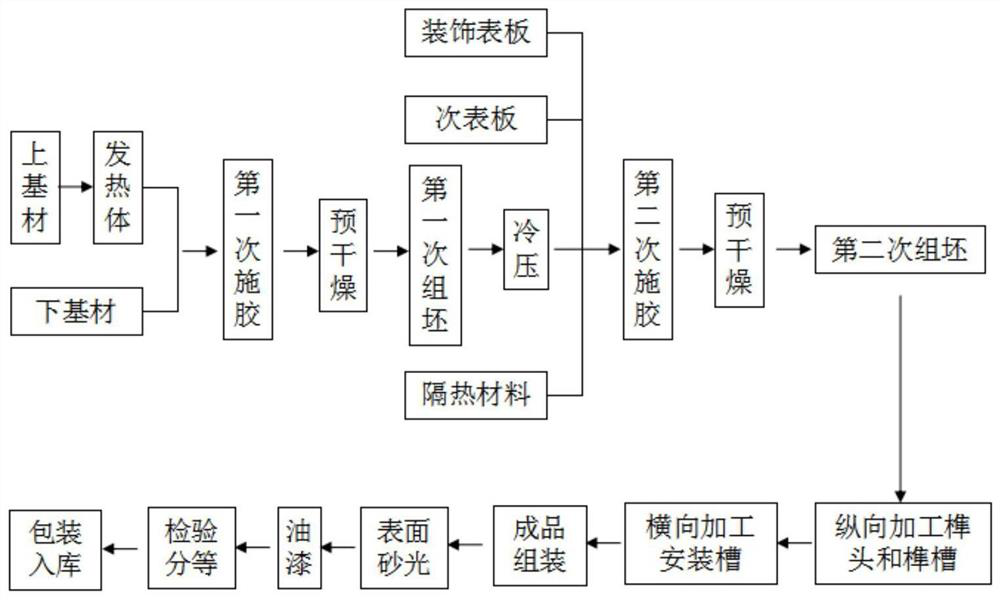

Method used

Image

Examples

Embodiment Construction

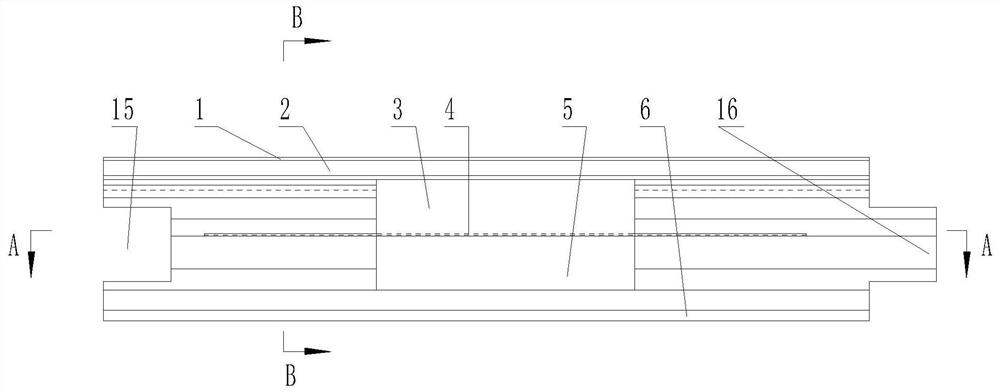

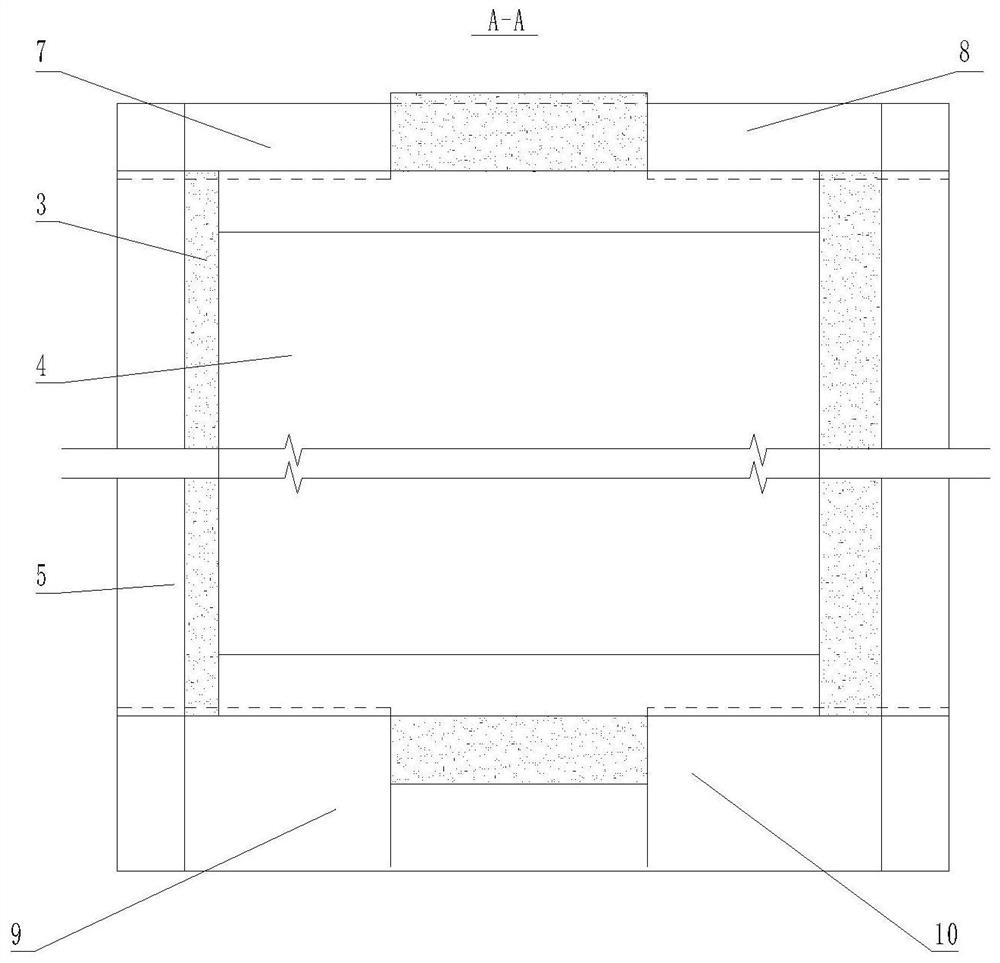

[0051] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0052] figure 2 , 3 , 4 and 10 represent a specific embodiment of the self-heating solid wood composite floor provided by the present invention, which mainly consists of decorative surface board 1, sub-surface board 2, upper base material 3, heating element 4, lower base material 5, heat insulation Material 6, electrical connection tenon groove 11, electrical connection tenon 12 and electrical connection conductor 13 etc. are formed, and it is processed by following technical scheme.

[0053]First of all, according to the market floor specifications, the decorative surface plate 1, the secondary surface plate 2, the upper base material 3, the heating element 4, the lower base material 5, and the heat insulation material 6 are processed into the required size, and the electrical connection is processed according to the requirements. Mortis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com