Electric heating floor and preparation method thereof

An electric heating floor and floor technology, applied in the field of floor heating floor manufacturing, can solve the problems of high installation and later maintenance costs, no mass production, high cost, etc., achieve low investment costs for factory construction, stable product quality, and avoid wet expansion and dry shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

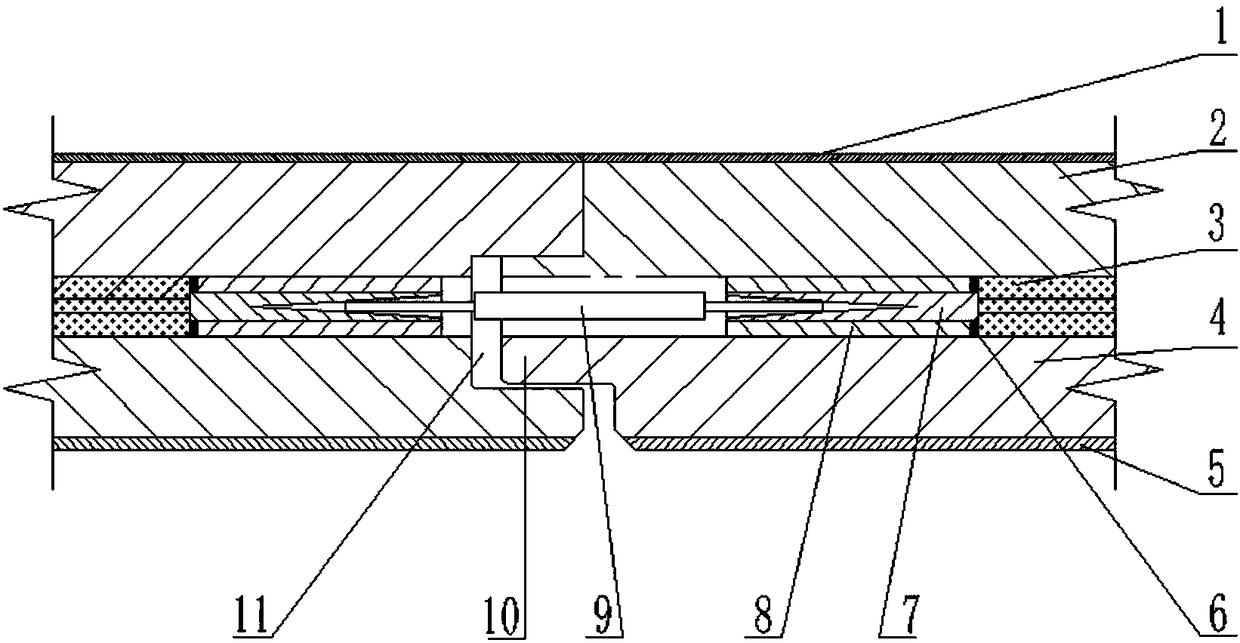

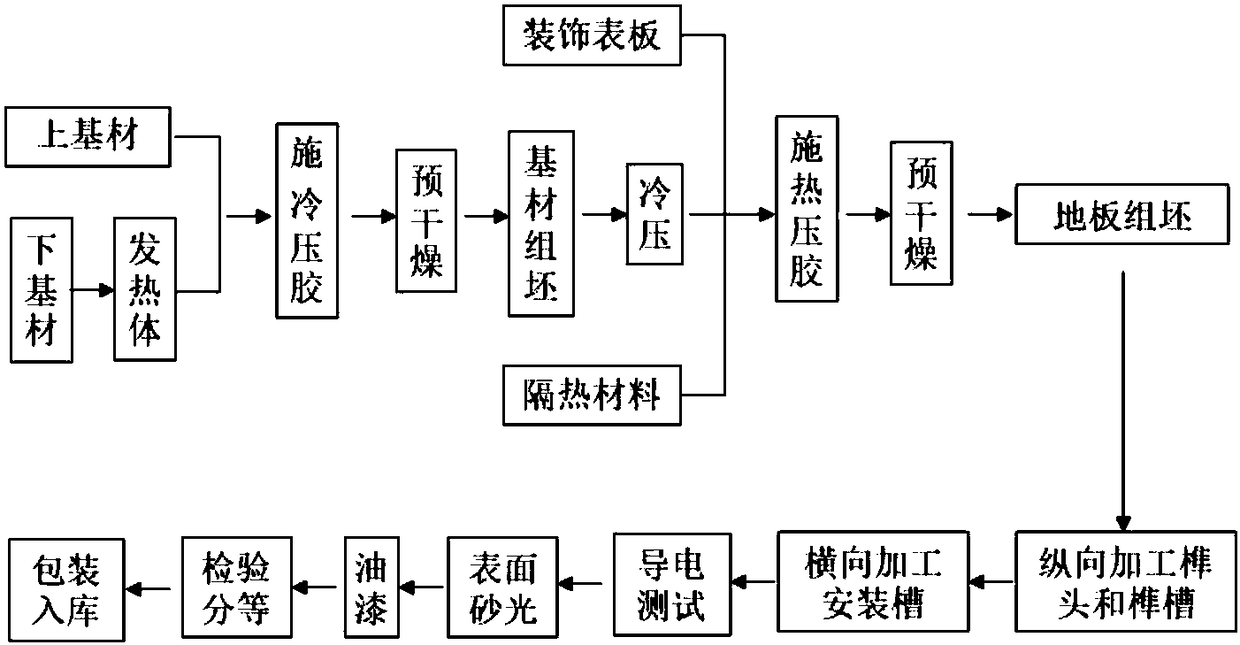

[0024] Such as figure 2 As shown, the preparation method of the electric heating floor of the present invention includes the following steps: a, raw material preparation; b, applying cold pressing glue; c, pre-drying; d, substrate assembly; Hot pressing glue; h, floor assembly; i, hot pressing; j, mortise, tenon; k, connecting the electric conductor to test whether it is conductive; l, subsequent processing (such as sanding, painting, inspection and grading, packaging storage) and other steps.

[0025] a. Raw material preparation: Process the decorative surface plate 1, the upper base material 2, the self-limiting temperature heating element 3, the lower base material 4, and the heat insulating material 5 into required sizes, and set up a heating element groove on the upper surface of the lower base material 4, And process the heating element as required, the two ends of the heating element are packaged with the electric connection groove 8 embedded with the copper sleeve 7....

Embodiment

[0038]Firstly, according to the market floor specifications, process the decorative surface plate 1, the upper base material 2, the self-limiting temperature heating element 3, the lower base material 4, and the heat insulation material 5 into required sizes, and process the copper sleeve 7, Electric connection slot 8 and electric conductor 9. Among them, the decorative surface plate 1 is made of Mandshurica mandshurica, with a thickness of 1mm; the upper substrate 2 is a high thermal conductivity formaldehyde-free fiberboard, with a thickness of 6mm; The electric connection groove 8 of the copper sleeve 7; the lower base material 4 is a poplar multi-layer solid wood composite board with a thickness of 8 mm, and the upper surface of the lower base material 4 develops a heating body groove (that is, a longitudinal through groove), and the size is the same as that of the heating element section Dimensions: Heat insulation material 5 is made of aluminum foil heat insulation film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com