Resistor type electric reactor and manufacturing method thereof

A production method and reactor technology, applied in the direction of resistors, resistor manufacturing, other resistor networks, etc., can solve the problems of resistors such as poor wind resistance, earthquake resistance and pollution resistance, cumbersome transportation and installation work, and achieve high insulation levels , Strong shock resistance and high insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

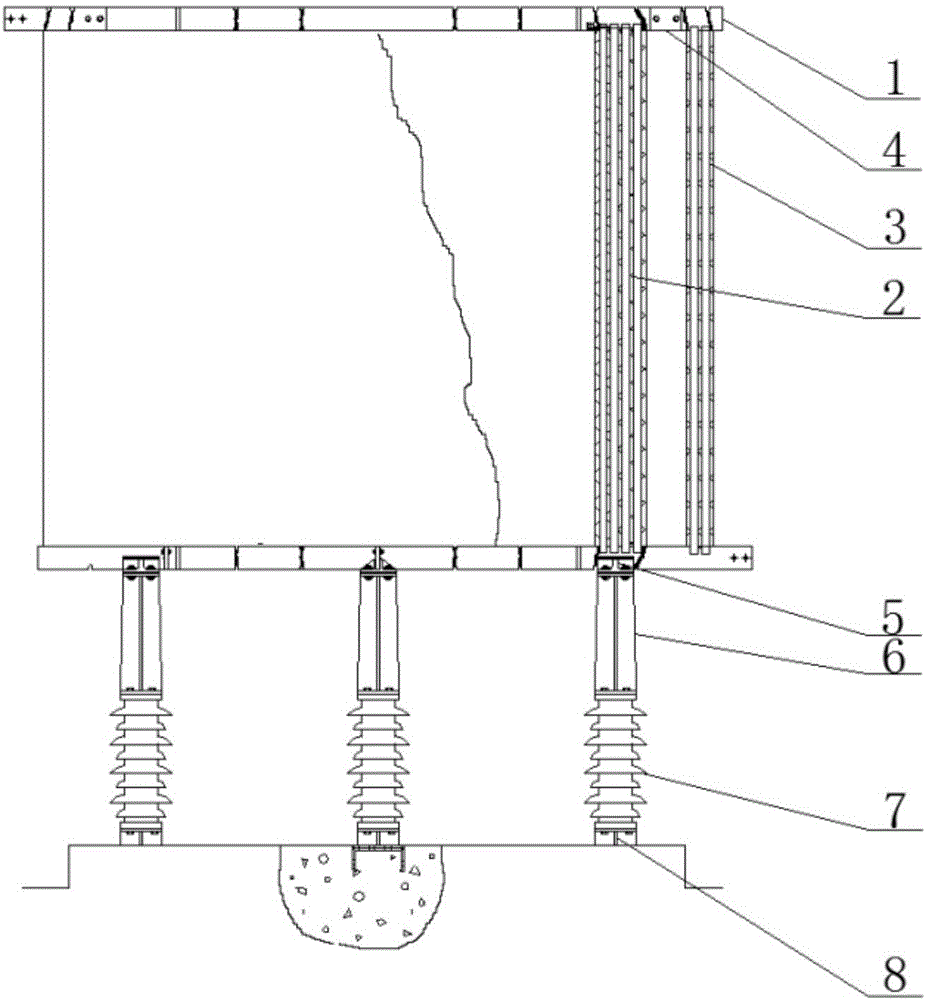

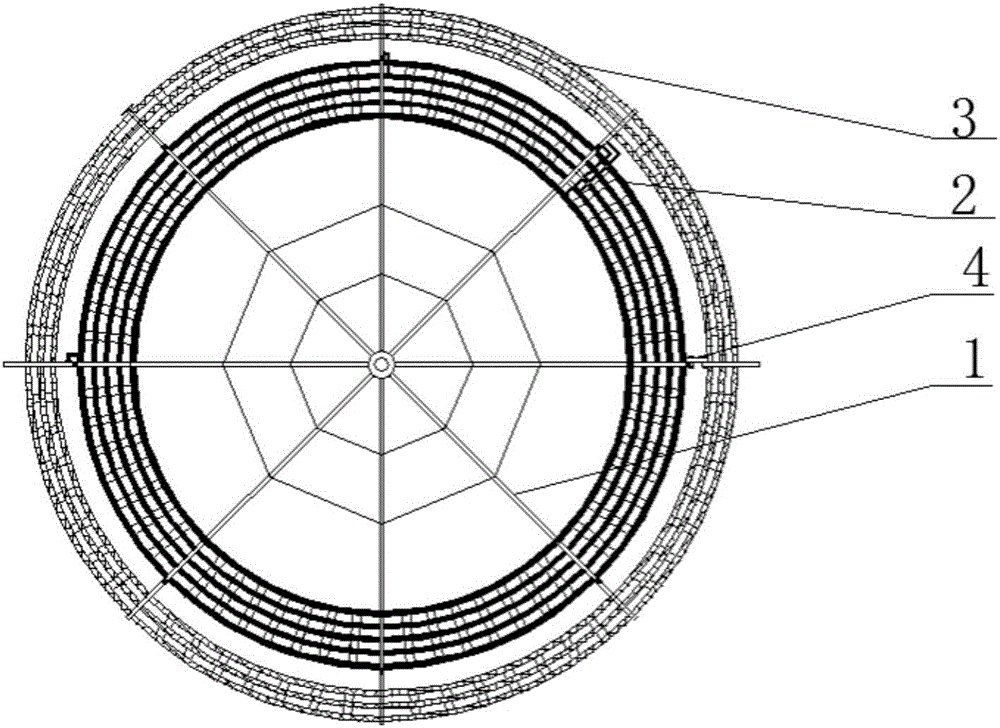

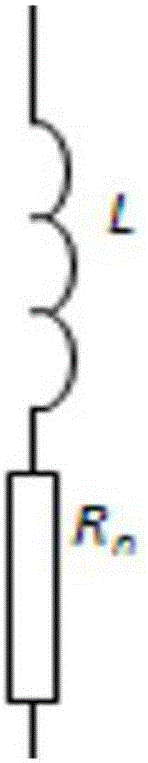

[0027] like figure 1 , figure 2 As shown, the resistive reactor includes a conductive arm star frame 1, an inductive coil 2 is installed inside the conductive arm star frame 1 and a non-inductive coil 3 surrounds the inductive coil 2, and the conductive arm star frame 1 is provided with a detachable The conversion board 4, a conductive arm of the inductive coil 2 and a conductive arm of the non-inductive coil 3 are connected through a detachable conversion board 4, and the detachable conversion board 4 is a metal conductive board or an epoxy board.

[0028] The detachable conversion board 4 is connected between the conductive arm of the inductive coil 2, that is, the reactor coil, and the non-inductive coil 3, that is, the resistor coil. When the resistor and the reactor need to be connected in parallel, a metal conductive plate is installed; when the resistor and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com