Microwave and light wave compound de-enzyme process

A light wave and de-enzyming technology, which is applied in tea treatment before extraction, can solve the problem of low energy consumption in the de-enzyming process, and achieve the effects of high energy utilization, short heating time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

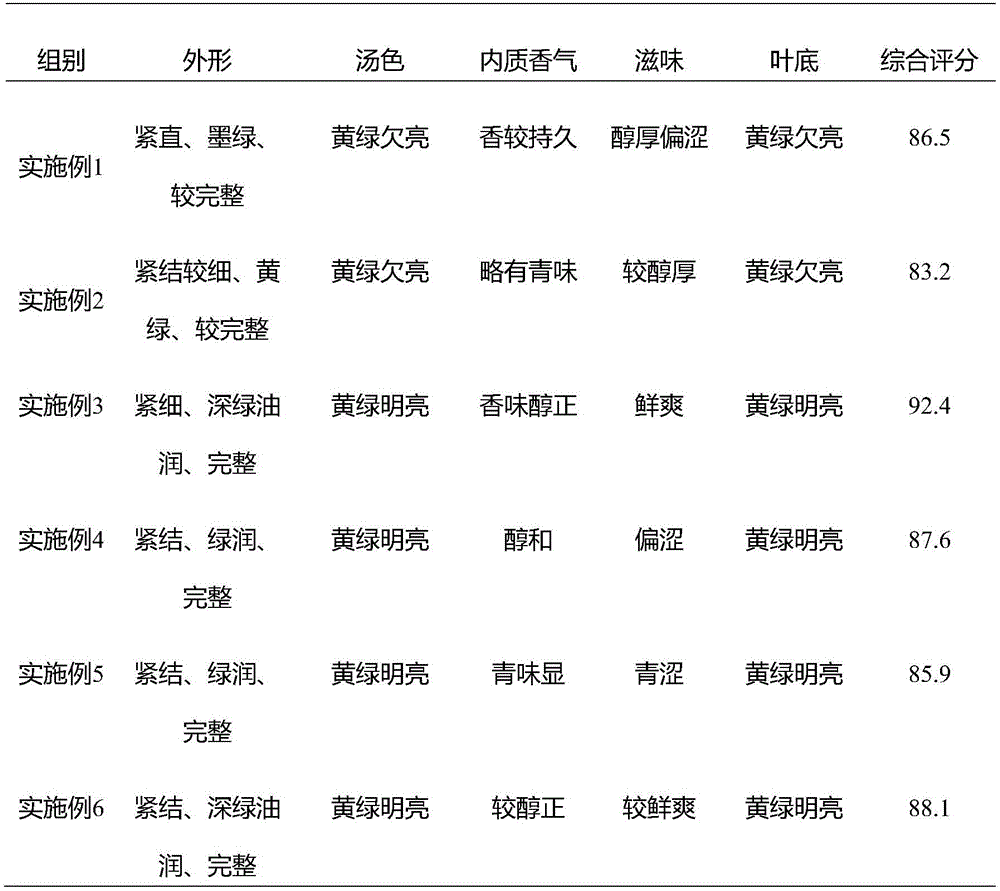

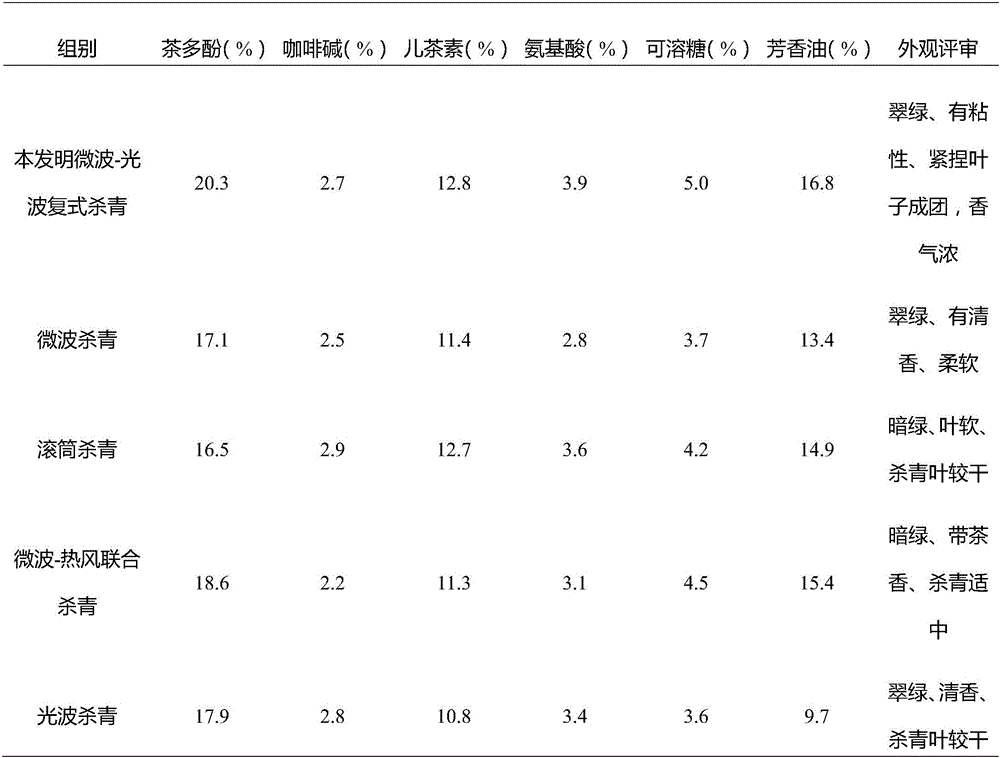

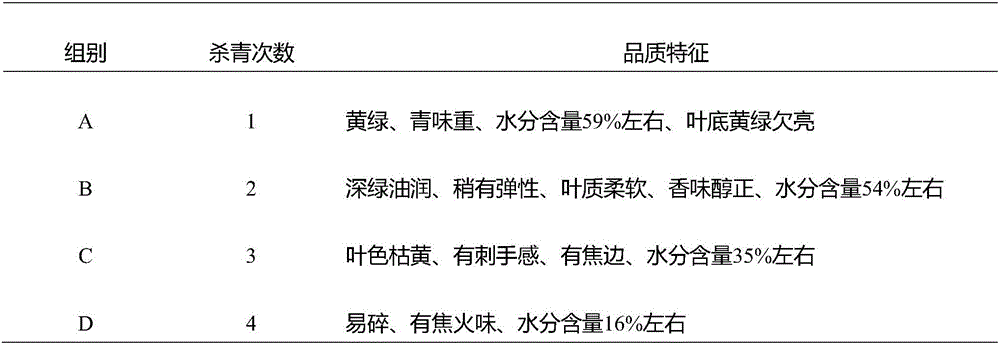

Examples

Embodiment 1

[0024] (1) Spread green: Pick green tea shoots or leaves that meet the standards, spread them on a clean utensil, the thickness of the spread is 5 cm, the time is 7 hours, turn the leaves every hour, and the spread time is not suitable It is too long to avoid stuffy smell, until the water content of the leaves is 65%, and the weight loss rate reaches 16%. At this time, the leaves become soft and give off a delicate fragrance, and the greening stage can be entered;

[0025] (2) Fixing: use microwave and light wave compound fixing machine to fix the green leaves, set the microwave power of the fixing bin to 800W, and the light wave power to 1000W, when the predetermined temperature is 80-82°C, put the leaves to be fixed on the conveyor belt, When the blade reaches the greening chamber, it will beat and move forward continuously with the vibrating plate, so that the blade will be heated evenly and keep for 1 minute;

[0026] (3) Kneading: quickly transport the green leaves to the...

Embodiment 2

[0030] (1) Spread green: Pick green tea shoots or leaves that meet the standards, spread them on a clean utensil, the thickness of the spread is 6 cm, the time is 12 hours, turn the leaves every hour, and the spread time is not suitable It is too long to avoid stuffy smell, until the water content of the leaves is 67%, and the weight loss rate reaches 18%. At this time, the leaves become soft and give off a delicate fragrance, and the greening stage can be entered;

[0031] (2) Fixing: use microwave and light wave compound fixing machine to fix the green leaves, set the microwave power of the fixing bin to 1000W, and the light wave power to 700W, when the predetermined temperature is 82-84°C, put the leaves to be fixed on the conveyor belt, When the blade arrives in the killing chamber, it will beat and move forward continuously with the vibrating plate, so that the blade will be heated evenly and keep for 3 minutes;

[0032] (3) Kneading: Quickly transport the green leaves to...

Embodiment 3

[0036] (1) Spread green: Pick green tea shoots or leaves that meet the standards, spread them on a clean utensil, the thickness of the spread is 6 cm, the time is 10 hours, turn the leaves every hour, and the spread time is not suitable It is too long to avoid stuffy smell, until the water content of the leaves is 68%, and the weight loss rate reaches 17%. At this time, the leaves become soft and give off a delicate fragrance, and the greening stage can be entered;

[0037] (2) Fixing: Use microwave and light wave compound fixing machine to fix green leaves. Set the microwave power of the fixing bin to 1200W, and the light wave power to 800W. After reaching the predetermined temperature of 85-87°C, put the green leaves to be fixed on the conveyor belt. When the blade arrives in the killing chamber, it will beat and move forward continuously with the vibrating plate, so that the blade will be heated evenly and keep for 2 minutes;

[0038] (3) Kneading: quickly transport the gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com