Detachable finger toothbrush and manufacturing method thereof

A detachable, toothbrush technology, applied in the direction of brushes, brush bodies, bristles, etc., can solve the problems of incomplete removal, large tooth damage due to tooth wear, and long time required, so as to reduce the use of bracket materials, softness and hardness Appropriate, structurally simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

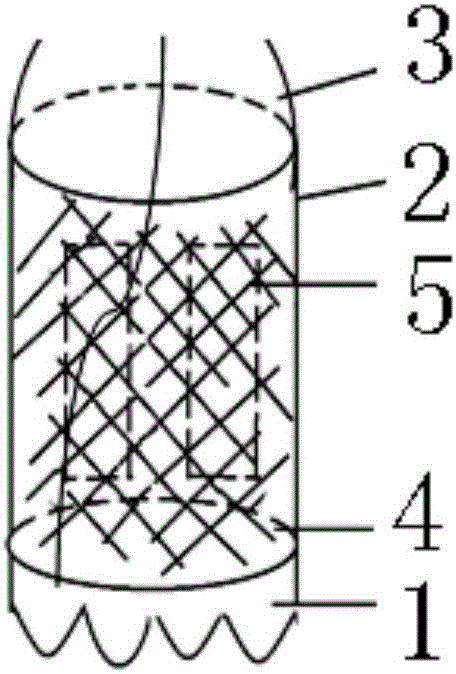

[0039] Such as figure 1 As shown, the detachable fingertip toothbrush includes a fingertip body and bristles 5, wherein the fingertip body is a hollow structure, the fingertip body is used to be placed on a finger, and the bristles 5 are detachably arranged on the fingertip body. The material is loofah.

[0040] Bristles 5 are made of pure natural plant-derived loofah, which is low in cost and easy to obtain. It is soft and elastic when exposed to water. It also reduces the degree of wear and tear on the teeth, and also helps to stabilize the teeth and prevent gingival recession by massaging the gums.

[0041] The bristles 5 are fixed on the finger cot body through elastically deformable finger cot rings. Specifically, the bristles are pressed on the cylindrical finger body through the finger ring, and the finger ring includes a finger ring I3 and a finger ring II4 arranged separately up and down. The finger cot body includes a base 1 and a finger cot bracket 2 arranged on ...

Embodiment 2

[0049]Except that the base is zigzag and other irregular edges etc. to facilitate the bristles to dry and keep hygienic, all the other are the same as embodiment 1.

Embodiment 3

[0051] Except that the base is designed as a personalized signature, all the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com