Device for oral implantation positioner for drilling hole and method of manufacturing handle of device

A locator and handle technology, which is applied in the directions of dental drilling, dental implants, medical science, etc., can solve the problems that the handle does not have anti-aging, low structural strength, poor drilling effect, etc., and achieves good drilling effect, High structural strength and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

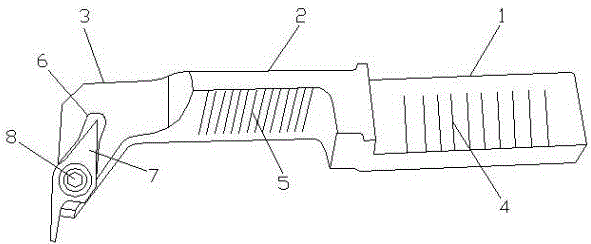

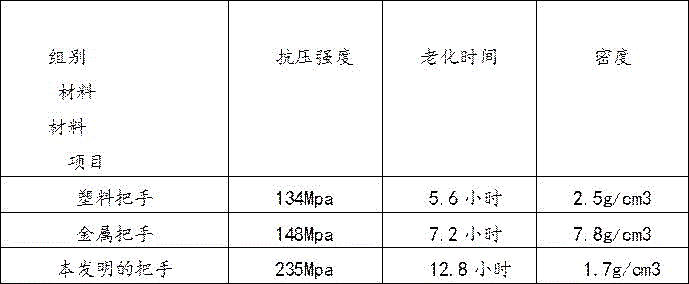

[0024] A drilling device for an oral implant positioner, comprising a handle 1, a connecting piece 2 and a bending part 3, the handle 1, the connecting piece 2 and the bending part 3 are integrally formed, the handle 1 is arranged in a rectangular shape, and the The handle 1 and the connector 2 are vertically arranged, the handle 1 is provided with first anti-skid lines 4, the first anti-skid lines 4 are equidistantly distributed, and the connector 2 is provided with second anti-skid lines 5, so The second anti-slip lines 5 are equidistantly distributed, and the bending portion 3 is bent horizontally downward. A groove 6 is arranged on the bending portion 3, and a blade 7 is installed in the groove 6, so that The blade 7 is made of tungsten alloy, and the blade 7 is set in a rhombus shape. A hexagonal countersunk screw 8 is installed in the middle of the blade 7, and the hexagonal countersunk screw 8 passes through the blade 7 and the bending part 3 in turn. The handle 1 is ma...

Embodiment 2

[0035] A drilling device for an oral implant positioner, comprising a handle 1, a connecting piece 2 and a bending part 3, the handle 1, the connecting piece 2 and the bending part 3 are integrally formed, the handle 1 is arranged in a rectangular shape, and the The handle 1 and the connector 2 are vertically arranged, the handle 1 is provided with first anti-skid lines 4, the first anti-skid lines 4 are equidistantly distributed, and the connector 2 is provided with second anti-skid lines 5, so The second anti-slip lines 5 are equidistantly distributed, and the bending part 3 is bent horizontally downwards, and a groove 6 is arranged on the bending part 3, and a blade 7 is installed in the groove 6, so that The blade 7 is made of tungsten alloy, and the blade 7 is set in a rhombus shape. A hexagonal countersunk screw 8 is installed in the middle of the blade 7, and the hexagonal countersunk screw 8 passes through the blade 7 and the bending part 3 in turn. The handle 1 is mad...

Embodiment 3

[0046] A drilling device for an oral implant positioner, comprising a handle 1, a connecting piece 2 and a bending part 3, the handle 1, the connecting piece 2 and the bending part 3 are integrally formed, the handle 1 is arranged in a rectangular shape, and the The handle 1 and the connector 2 are vertically arranged, the handle 1 is provided with first anti-skid lines 4, the first anti-skid lines 4 are equidistantly distributed, and the connector 2 is provided with second anti-skid lines 5, so The second anti-slip lines 5 are equidistantly distributed, and the bending part 3 is bent horizontally downwards, and a groove 6 is arranged on the bending part 3, and a blade 7 is installed in the groove 6, so that The blade 7 is made of tungsten alloy, and the blade 7 is set in a rhombus shape. A hexagonal countersunk screw 8 is installed in the middle of the blade 7, and the hexagonal countersunk screw 8 passes through the blade 7 and the bending part 3 in turn. The handle 1 is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com