Green and environment-friendly solid dispersion taking porous starch as carrier and preparation method thereof

A technology of solid dispersion and porous starch, which is applied in the field of medicine and achieves the effects of improved solubility, better in vitro dissolution, and easy mass preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Another aspect of the embodiments of the present invention provides a method for preparing the aforementioned green solid dispersion with porous starch as a carrier, including:

[0037] Provide porous starch;

[0038] The porous starch is uniformly mixed with the drug components, and the drug components are evenly distributed on the surface and pores of the porous starch to form the green and environment-friendly solid dispersion with the porous starch as the carrier.

[0039] As one of the preferred embodiments, the mass ratio of the porous starch to the pharmaceutical ingredient is 4:1-12:1.

[0040] Preferably, the porous starch is prepared by a composite enzyme method.

[0041] Further, the drug ingredients include poorly soluble drugs, such as andrographolide.

[0042] As one of the preferred embodiments, the preparation method includes: mixing the porous starch and the insoluble drug uniformly in a mass ratio of 4:1 to 12:1, and then adding distilled water whose...

Embodiment 1

[0057] The preparation method of the andrographolide solid dispersion of the present embodiment is as follows:

[0058] Mix the porous starch as the carrier with andrographolide in a mass ratio of 4:1, then add water with a quality of 100% of the porous starch and stir evenly, and place the mixture in a grinder for grinding, wherein the parameters of the grinder are: The rotation speed is 200r / min, the ball-to-material ratio is 2:1, the ball milling time is 1h, and the filler rate is 10%. The solid obtained after grinding is dried, ground, sieved, and tabletted to obtain a solid dispersion of andrographolide.

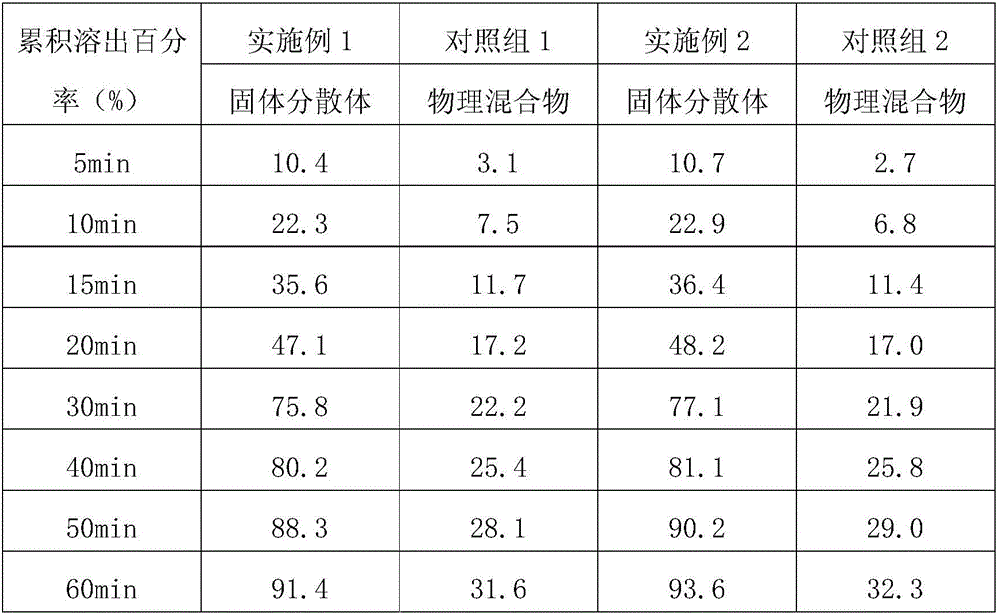

[0059]Solubility evaluation experiment: according to the first method of dissolution measurement (basket method), with 0.2% SDS 900mL as the dissolution medium, the rotating speed is 100r / min, and 5 tablets (known content) of the andrographolide solid dispersion of the present embodiment are taken Place them in the rotating baskets respectively, and take 8 mL samples a...

Embodiment 2

[0063] The preparation method of the andrographolide solid dispersion of the present embodiment is as follows:

[0064] Carrier porous starch and andrographolide are mixed evenly in a mass ratio of 12:1, then add water with a quality of 120% of the porous starch quality and stir evenly, and place the mixture in a grinder for grinding, wherein the parameters of the grinder are: the speed is 500r / min, the ball-to-material ratio is 8:1, the ball milling time is 4h, and the filler rate is 35%. The solid obtained after grinding is dried, ground, sieved, and tabletted to obtain a solid dispersion of andrographolide.

[0065] Solubility evaluation experiment: according to the first method of dissolution measurement (basket method), with 0.2% SDS 900mL as the dissolution medium, the rotating speed is 100r / min, and 5 tablets (known content) of the andrographolide solid dispersion of the present embodiment are taken Place them in the rotating baskets respectively, and take 8 mL samples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com