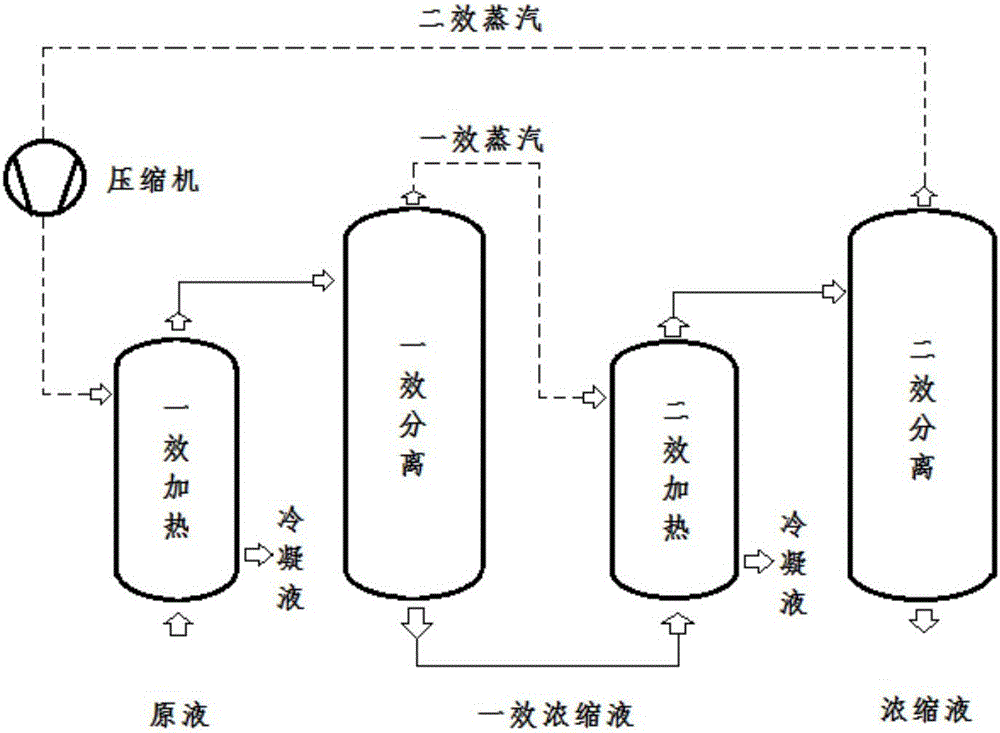

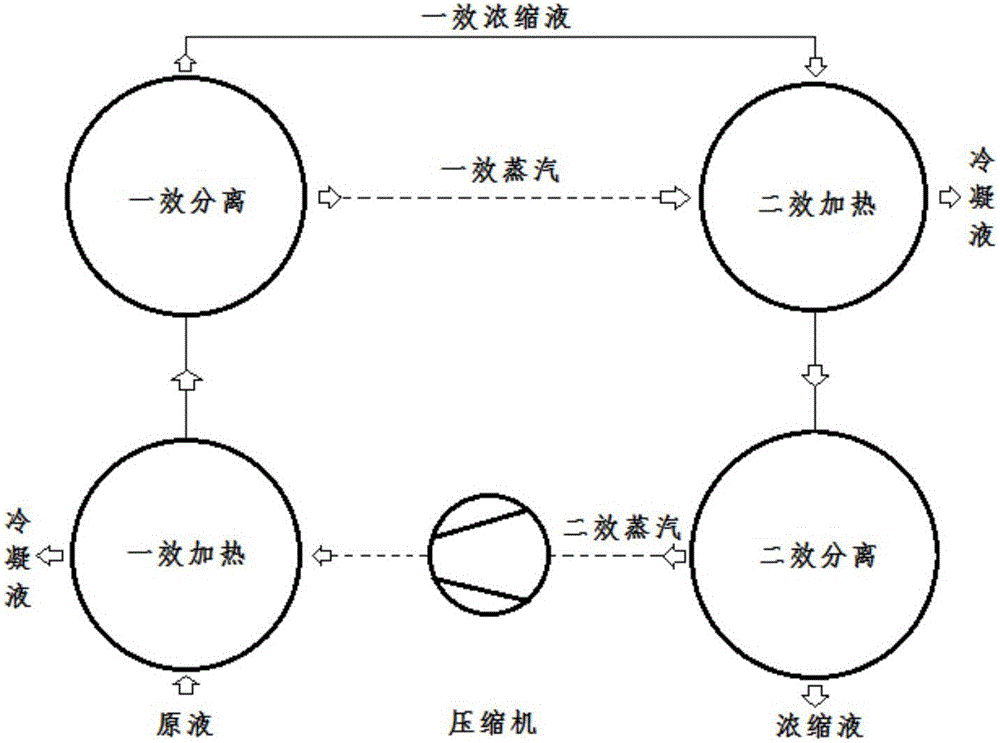

MVR evaporation system employing two-effect parallel flow method

An evaporation system and two-effect technology, applied in the field of energy-saving technology, can solve the problem of high cost of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The original liquid is heated and evaporated by the first-effect equipment to separate the first-effect steam into a first-effect concentrated liquid, then enters the second-effect equipment for further evaporation and concentration, and then discharges into the subsequent process flow. When necessary, part of the concentrated liquid is forced to circulate back to the first-effect equipment. Continue to evaporate. The first-effect steam (that is, the secondary steam separated from the first effect) is directly used as the heat source of the second-effect heating equipment, and the second-effect steam (that is, the secondary steam separated from the second effect) enters the first effect after being compressed by the compressor. The heating device is used as the sole heat source. After heat exchange, the steam loses latent heat and condenses into liquid to be discharged. When it is necessary to make up for the heat balance of the system, open the raw steam input port in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com