Vacuum filtering device

A filter device and vacuum technology, applied in the direction of filtration separation, gravity filter, fixed filter element filter, etc., can solve the problems of difficult cleaning, non-replacement, high cost, etc., and achieve the effect of easy cleaning, convenient fixing, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

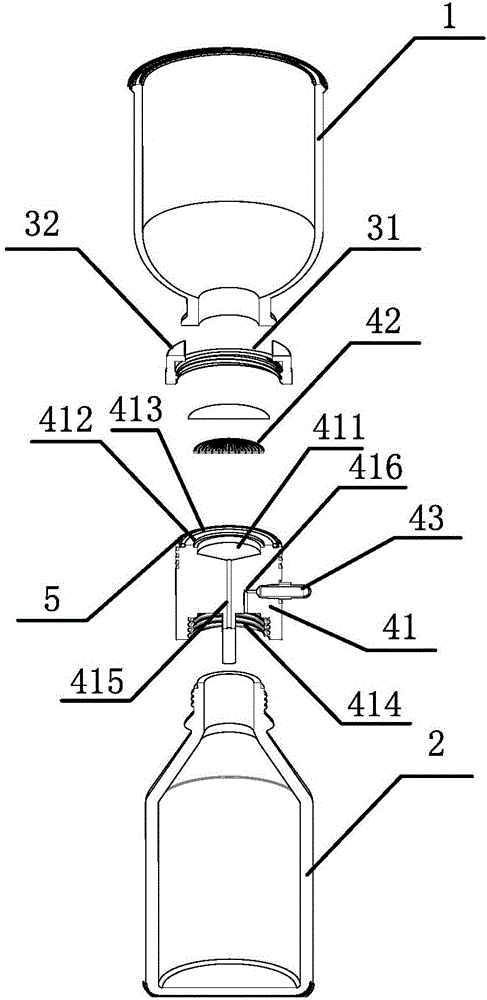

[0032] figure 1 Schematically provides a simplified structural diagram of the vacuum filter device of the present embodiment, as figure 1 As shown, the vacuum filter device includes: a filter cup 1, a filtrate bottle 2, and the vacuum filter device further includes:

[0033] A snap ring, the snap ring includes a ring 31 and a snap ring arm 32, the ring has a first internal thread, and the snap ring is connected to the filter main body through the first internal thread; the snap ring arm has at least two , for buckling and fixing the filter cup;

[0034] A filter subject, the filter subject comprising:

[0035] Body 41, the body is made of polytetrafluoroethylene; the upper bottom surface of the body is provided with a first groove 411, and a first blocking portion 412 is provided in the first groove; the upper side of the body A first external thread matching the first internal thread is provided; a second groove 414 is provided on the lower bottom surface of the body, and ...

Embodiment 2

[0049] This embodiment provides a vacuum filtration device according to Embodiment 1 of the present invention. In this embodiment, the first groove includes three parts, which are respectively an inverted cone part, a filter membrane support part and a sealing ring from bottom to top. The blocking part, the filter membrane supporting part and the sealing ring blocking part are cylindrical, and the bottom surface radius of the sealing ring part blocking part is larger than the bottom surface radius of the filter membrane supporting part and larger than the bottom surface radius of the inverted conical part, forming a second step surface, and the two-stage stepped surface constitutes the second blocking portion and the first blocking portion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com