Metal-film filtering screen and air purifying device

An air filter device and filter screen technology, applied in the field of air purification, to achieve the effect of increasing efficiency, reducing the service life of consumables, and having strong anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

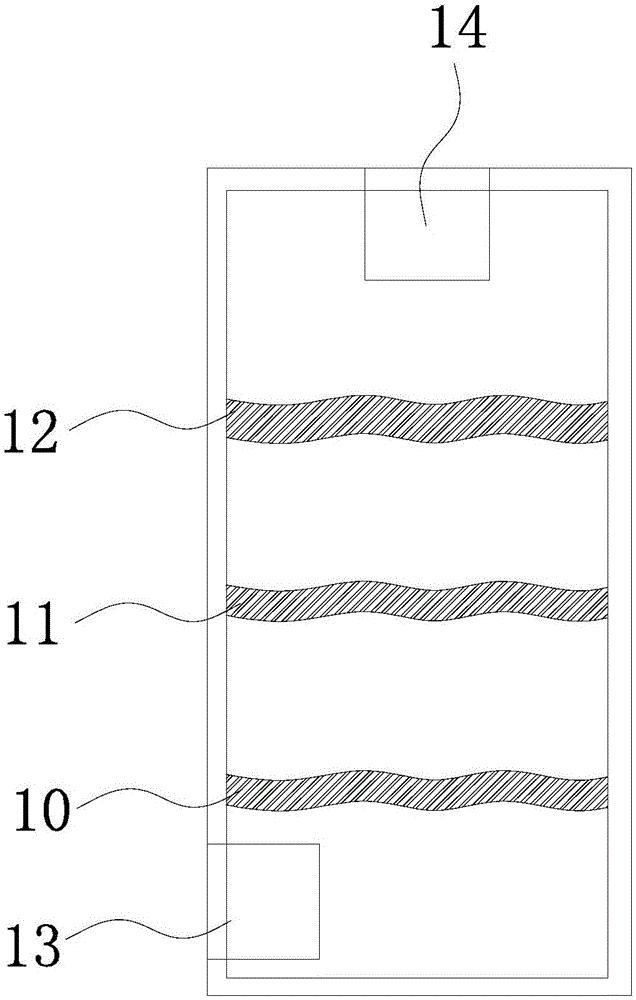

[0035] Please refer to figure 1 As shown, the embodiment of the present invention provides a kind of metal film filter screen, is installed in the air filter device, and air filter device is provided with air inlet 13 and air outlet 14, and metal film filter screen comprises primary effect filter screen 10, medium effect Filter screen 11 and efficient filter screen 12.

[0036] The primary filter 10 can filter the large particle impurities visible to the naked eye. As the first filter barrier, the pore size of the primary filter 10 is relatively larger, and the filtration level of the primary filter 10 is G1-G4. 10 is closer to the air inlet 13 than the medium-efficiency filter 11 , usually, the primary-efficiency filter 10 is arranged at the air inlet 13 .

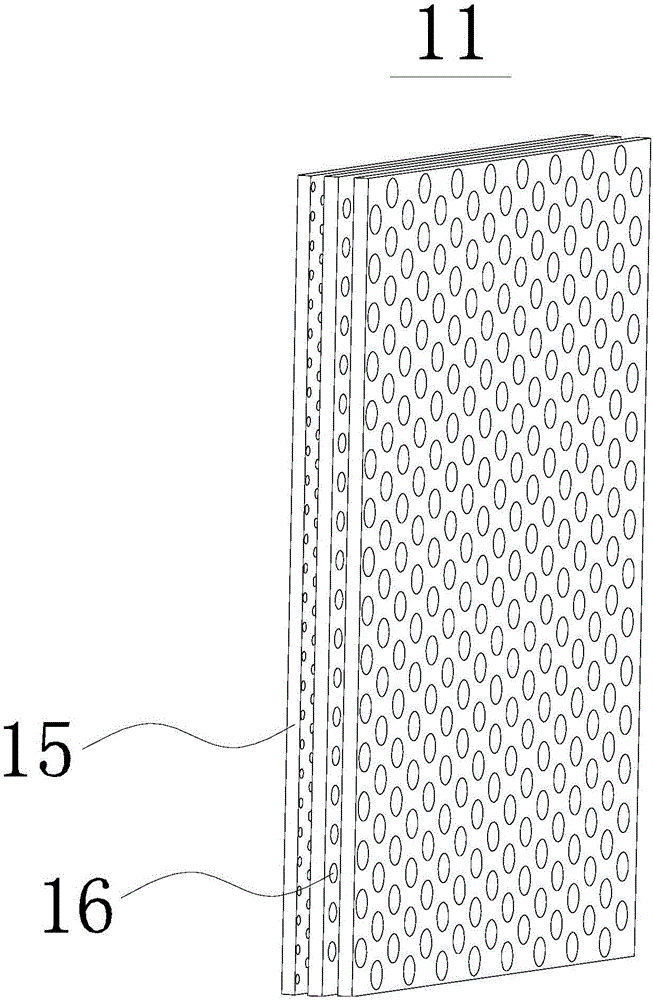

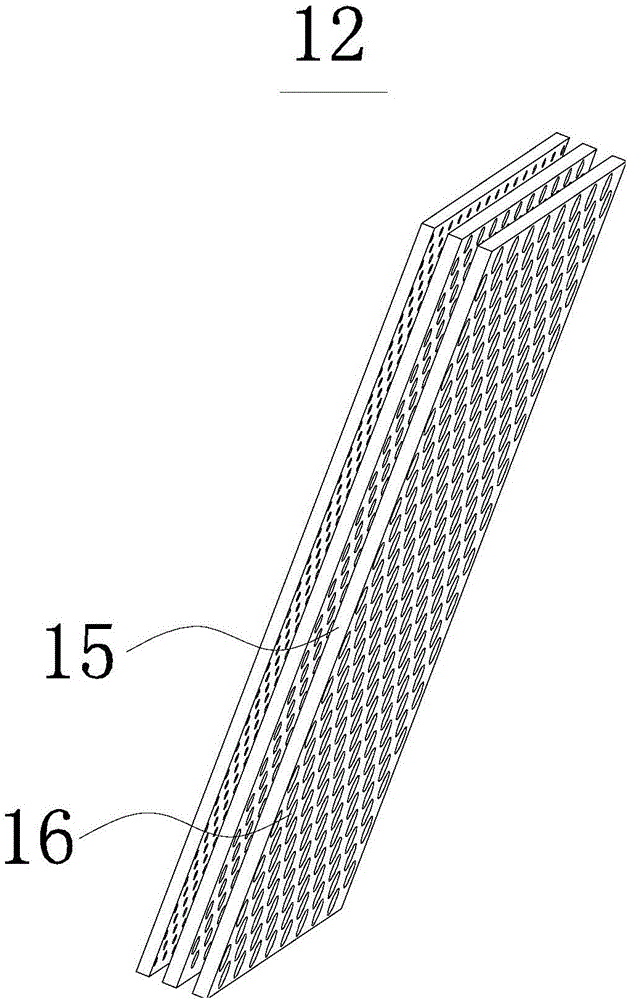

[0037] Both the medium-efficiency filter 11 and the high-efficiency filter 12 can filter tiny particles in the air such as PM2.5. Filters finer particles.

[0038] The medium-efficiency filter 11 is closer to the air i...

Embodiment 2

[0062] Please refer to Figure 6 As shown, Embodiment 2 of the present invention also provides an air purification device 100, including a housing 20, an electrostatic precipitator 21, an air heat treatment device 22, an initial effect filter 10, a blower 23 and the metal film in Embodiment 1 Filter.

[0063] Metal film filter screen, electrostatic precipitator 21, air heat treatment device 22 and air blower 23 are all arranged in housing 20 and communicate with each other, air purification device 100 is provided with air inlet end and air outlet end, primary effect filter screen 10 is arranged on inlet At the air end, the air heat treatment device 22 is arranged between the preliminary filter screen 10 and the electrostatic precipitator 21, the air blower 23 is arranged between the electrostatic precipitator 21 and the medium-effect filter screen 11, and the medium-effect filter screen 11 and the high-efficiency filter screen 12 are from One end of the air blower 23 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com