Preparation method of atomic state Ag-modified ZnO polycrystal nanobelt assembly structure with high hydrogen producing performance

A technology for assembling structures and nanobelts, which is applied in chemical instruments and methods, hydrogen, hydrogen production, etc., to achieve the effects of regular shape, improved photocatalytic activity, and broadened absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

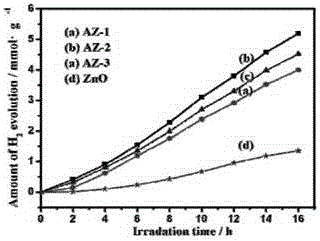

Embodiment 1

[0020] Weigh 0.06mol / L zinc acetate dihydrate and dissolve it in deionized water to obtain a clear solution A; weigh 0.036mol / L hexamethylenetetramine and 0.8mol / L urea in deionized water to obtain a clear solution B; Add solution B to solution A, add 5 mL of silver nitrate solution to the mixed solution, mix well to obtain a reaction system, transfer the mixed solution into a reaction vessel, react in an oven at 90°C for 12 hours, centrifuge, wash, and dry the solid It is roasted in a tube furnace at a roasting temperature of 300 DEG C. After holding for half an hour, the finished product is obtained.

Embodiment 2

[0022] Weigh 0.06mol / L zinc acetate dihydrate and dissolve it in deionized water to obtain a clear solution A; weigh 0.036mol / L hexamethylenetetramine and 0.3mol / L urea to dissolve in deionized water to obtain a clear solution B; Add solution B to solution A, add 5 mL of silver nitrate solution to the mixed solution, mix well to obtain a reaction system, transfer the mixed solution into a reaction vessel, react in an oven at 90°C for 12 hours, centrifuge, wash, and dry the solid It is roasted in a tube furnace at a roasting temperature of 300°C, and after holding for half an hour, the finished product is obtained.

Embodiment 3

[0024] Weigh 0.06mol / L zinc acetate dihydrate and dissolve in deionized water to obtain a clear solution A; weigh 0.036mol / L hexamethylenetetramine and 1.6mol / L urea to dissolve in deionized water to obtain a clear solution B; Add solution B to solution A, add 5 mL of silver nitrate solution to the mixed solution, mix well to obtain a reaction system, transfer the mixed solution into a reaction vessel, react in an oven at 90°C for 12 hours, centrifuge, wash, and dry the solid It is roasted in a tube furnace at a roasting temperature of 300 DEG C. After holding for half an hour, the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com