In-situ self-assembly preparation method of tetrasulfonated zinc phthalocyanine/zinc oxide compound membrane nano-material

A technology of zinc tetrasulfophthalocyanine and nanomaterials, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, special compound water treatment, etc., can solve problems such as low solubility and limitation, and achieve Improve the interface effect, high selectivity, and realize the effect of visible light response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

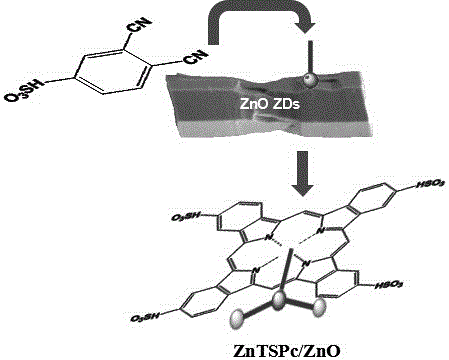

[0033] An in-situ self-assembly preparation method of a zinc tetrasulfophthalocyanine / zinc oxide composite membrane nanomaterial, the specific steps of which are:

[0034] (1) The ITO conductive glass was ultrasonically washed with cleaning agent, acetone, ethanol and deionized water respectively, with an interval of 10 minutes each time, and then dried in an oven at 80°C for later use;

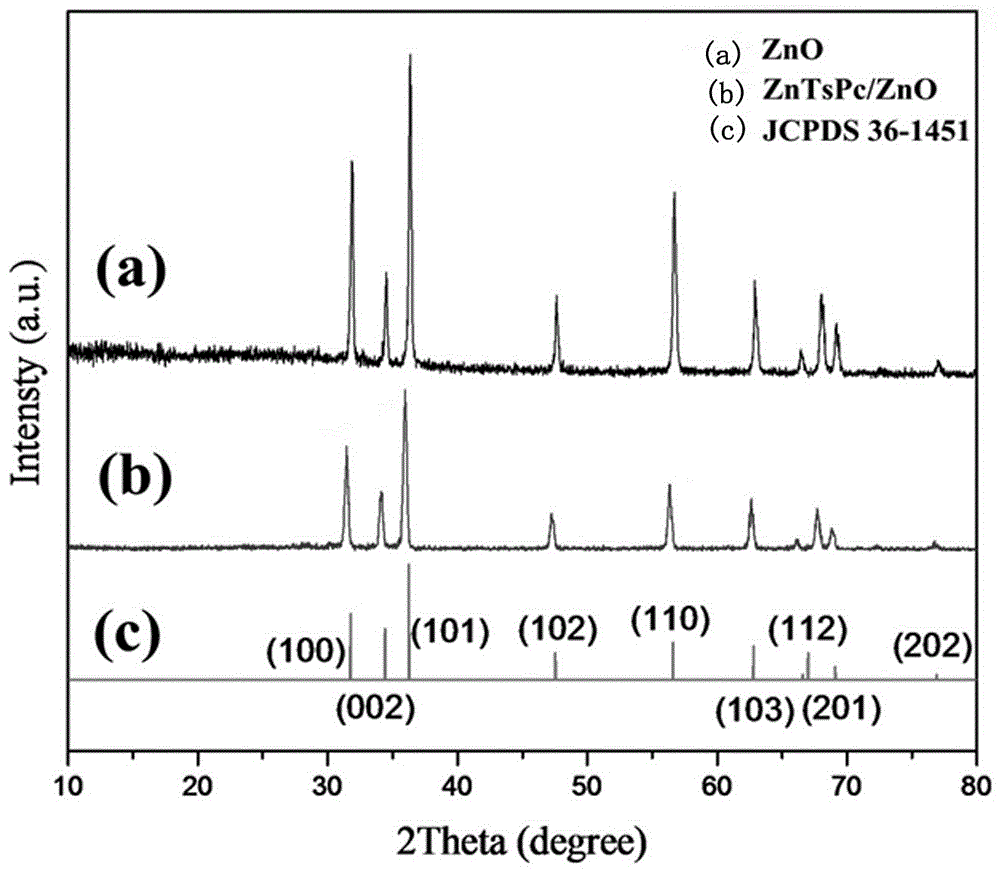

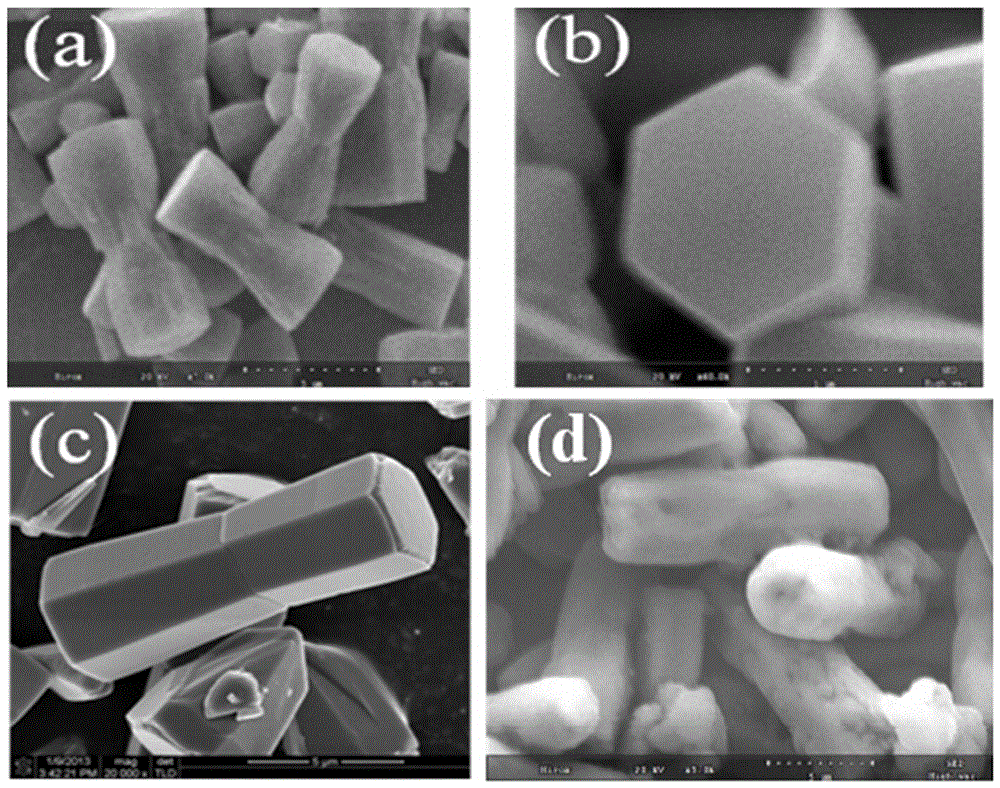

[0035] (2) Put the washed ITO into 200 mL containing Zn(CH) with a concentration of 20 mM. 3 COO) 2 and hexamethylenetetramine (HMTA); the beaker was placed in a 90°C water bath for 1 h, then the ITO was taken out, washed gently with deionized water, dried naturally, and finally placed in a muffle furnace for 300 calcined for 30 min at ℃, the heating rate was 5 ℃ / min, and finally the dumbbell-shaped ZnO nanofilm material attached to the ITO conductive glass was obtained;

[0036] (3) Dissolve 0.0416 g of sulfophthalonitrile in 40 mL of N,N-dimethylformamide (DMF), and ultrasonically dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com