Feed raw material micro-grinding system

A feed material and micro-grinding technology, which is applied in feed, grain processing, food science, etc., can solve the problems of increasing the difficulty of granulation, increasing equipment cost, increasing equipment load, etc., to avoid poor grinding effect and dust leakage , The effect of purifying the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

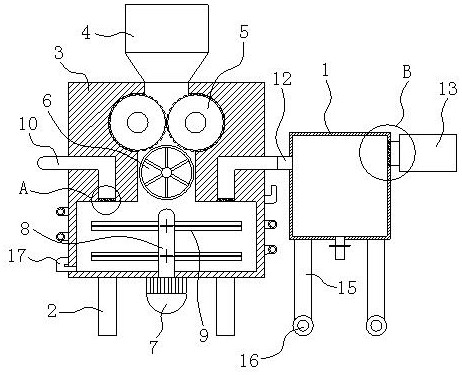

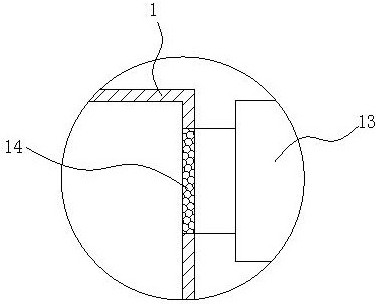

[0014] to combine Figure 1-4 A feed raw material micro-grinding system shown includes a pulverizer and a material transfer box 1 located on one side of the pulverizer. The pulverizer includes a support leg 2 and a main body 3 arranged on the support leg 2. The main body 3 The top is provided with a hopper 4, and the upper part of the main body 3 is provided with a reverse-shaped coarse crushing cavity, and the feed raw materials are initially crushed in the coarse crushing cavity. The top of the coarse crushing chamber communicates with the feed hopper 4, and the lower part of the main body 3 is provided with a fine crushing chamber connected to the bottom of the coarse crushing chamber, and the preliminarily crushed feed material is crushed again in the fine crushing chamber.

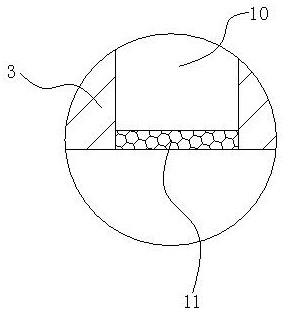

[0015] Two parallel rolling rollers 5 are arranged on the upper part of the coarse crushing chamber, and breaking rollers 6 are arranged on the lower part. The rolling roller 5 is used to crush the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap