Inside and outside spraying production equipment for pipe and pipe production method

A technology for producing equipment and pipes, applied in coating, spray booth, spray device, etc., can solve the problems of low product quality, high burner power, non-complete sealing, etc., to reduce gas source consumption and waste, good quality, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

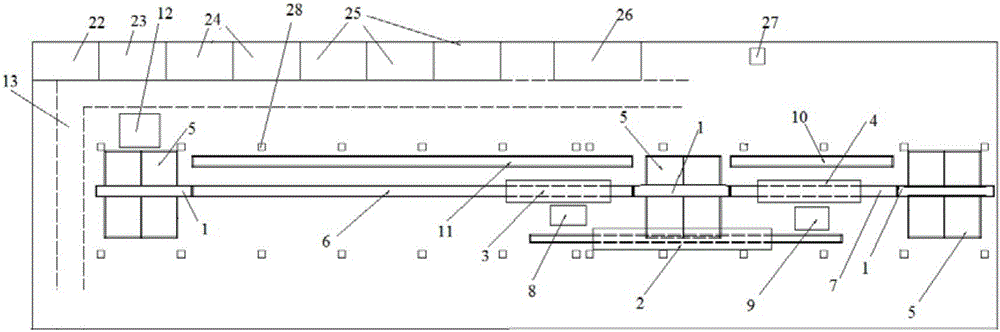

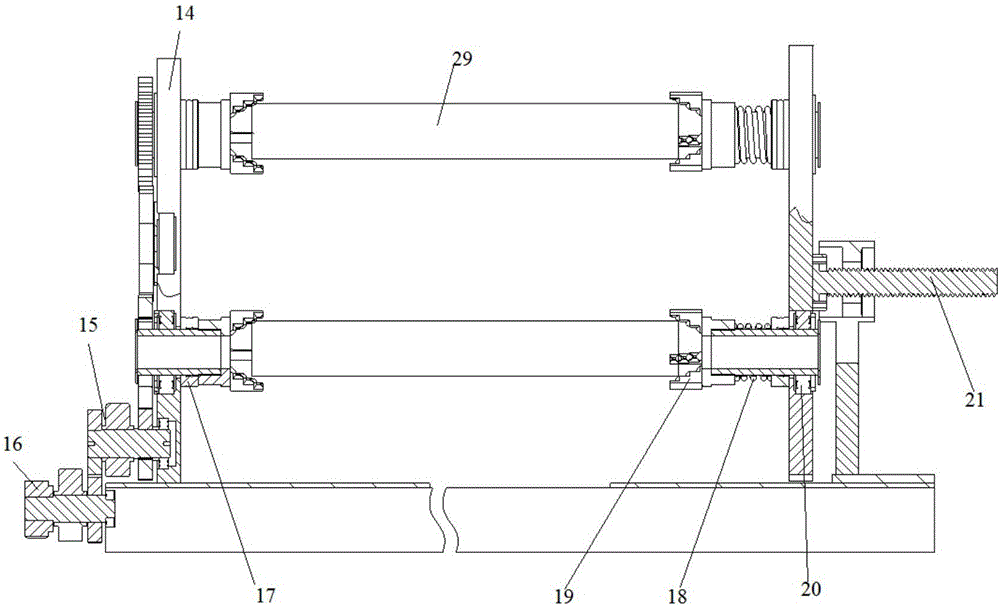

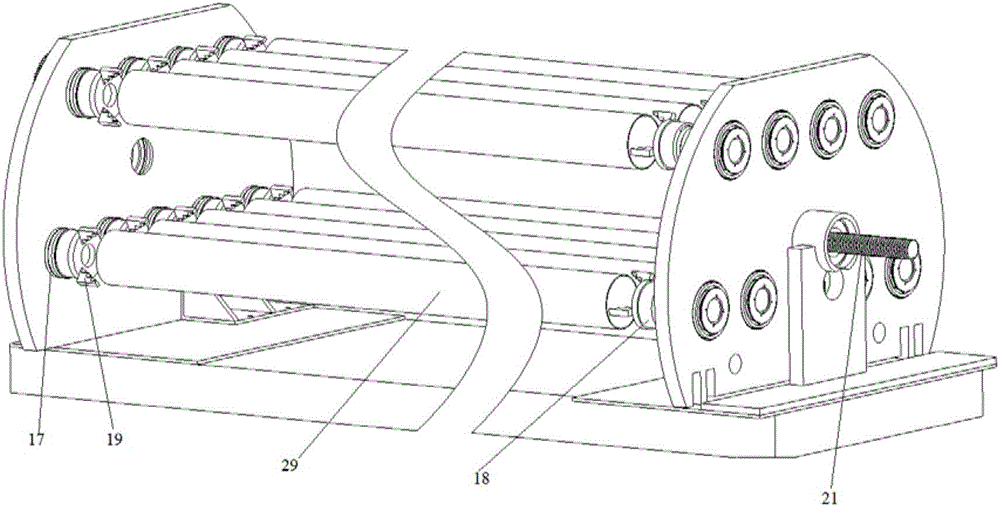

[0041] A kind of pipe material internal and external spraying production equipment, such as figure 1 with figure 2 As shown, it includes pipe conveying vehicle 1, curing furnace 3 (burner configuration 200,000-340,000 kcal), heating furnace 4 (burner configuration 340,000-500,000 kcal), internal and external spraying device 2 with rotary suction device The pipe delivery vehicle 1 is arranged on the delivery vehicle base 5, and the bottom surface of the delivery vehicle base 5 is provided with a pulley, and the pulley is arranged in the first slide rail 6, and the first slide rail 6 is arranged to pass through the curing furnace 3 and the heating furnace 4 internal;

[0042] Inside and outside spraying device 2 is arranged on the inboard position between curing furnace 3 and heating furnace 4, and inside and outside spraying device 2 is provided with the second slide rail 7 that passes inside and outside spraying device 2, and second slide rail 7 and curing furnace 3 and The...

Embodiment 2

[0053] The production equipment for internal and external spraying of pipes is similar to that of Example 1, the difference is that thirteen pipes are evenly spaced on both sides of the area where the pipe transport vehicle 1, the first slide rail 6, the second slide rail 7 and the internal and external spraying device 2 are located. 28 uprights.

[0054] Preferably, the columns 28 are all set as rectangular columns.

[0055] Preferably, the spraying area 22 , the spraying material cooling area 23 , the packaging area 24 , the pre-spraying treatment area 25 , the cooling area 26 and the manual spraying cabinet 27 are all arranged as rectangular areas.

[0056] Preferably, the first slide rail 6 , the second slide rail 7 , the third slide rail 10 , the fourth slide rail 11 and the fifth slide rail 13 are all set as rectangular slide rails.

[0057] Preferably, the body of the pipe transport vehicle 1 is set in a rectangular shape, and the base 5 of the transport vehicle is set...

Embodiment 3

[0065] A pipe production method, using the energy-saving type internal and external spray pipe production equipment such as embodiment 1 or embodiment 2, comprising the following steps:

[0066] In the first step, the pipe material 29 is loaded onto the pipe material delivery vehicle 1;

[0067] In the second step, the pipe 29 is loaded into a heating furnace, the heating time is 10-25 minutes, and the surface temperature of the pipe 29 is 200-230° C. during internal and external spraying;

[0068] The third step is to measure the temperature of the pipe 29;

[0069] In the fourth step, the pipe 29 is sprayed and plasticized by the internal and external spraying device 2;

[0070] The fifth step is to put the pipe 29 into the curing furnace 3 for curing, the curing time is controlled to be 12-18 minutes, and the temperature in the curing furnace 3 is 185°C±2°C.

[0071] Preferably, the cured pipe 29 is sequentially unloaded, inspected, marked, packaged and put into storage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com