Device and method for improving mechanical peeling performance for steel wire rods

A kind of mechanical and wire rod technology, which is applied in the field of devices for improving the mechanical peeling performance of wire rods. It can solve the problems of uneven oxide scale changes on the surface of wire rods, long cycles, and insignificant improvements in mechanical peeling effects, etc., to achieve improved wire rod performance. Effect of improving peeling efficiency and peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For further describing the present invention, below in conjunction with accompanying drawing and embodiment the present invention will be further described:

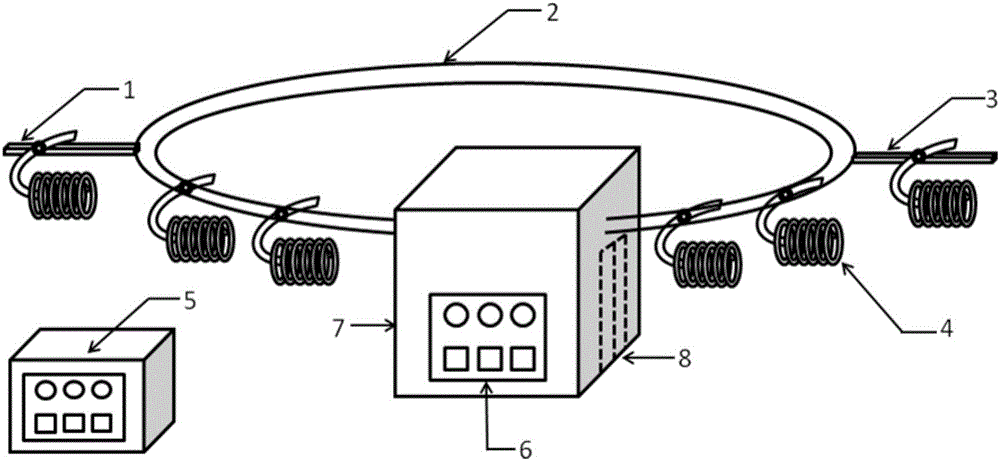

[0021] like figure 1 As shown, a device for improving the mechanical peeling performance of wire rods includes a work chamber, a mechanical transfer device, and a temperature / humidity control device; the mechanical transfer device includes a feeding channel, an annular channel and a feeding channel; The transmission speed of the unloading channel is controlled by a speed change device. The temperature / humidity control device can adjust the temperature, humidity and ventilation in the working chamber. There is a thermal insulation layer between the inner wall and the outer wall of the working compartment, and a row of isolation curtains are placed at the entrance and exit on both sides of the fuselage.

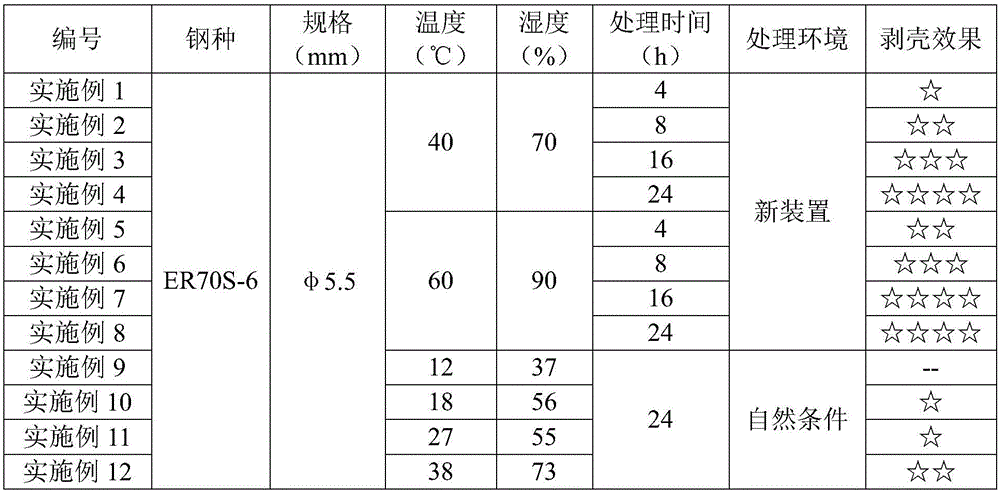

[0022] Utilize the method for improving the mechanical peeling performance of wire rod of above-mentioned devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com