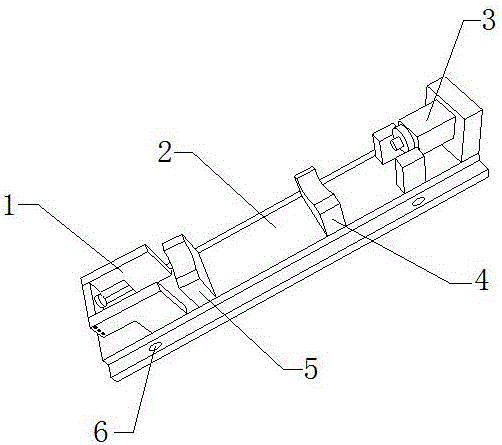

Roller D-face machining jig of machining center

A machining center and roller technology, applied in the direction of chucks, etc., can solve problems such as difficulty in ensuring product processing quality, inaccurate positioning of fixtures, and single clamping of chucks, etc., to avoid product scrap, fast and accurate positioning, and ensure processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

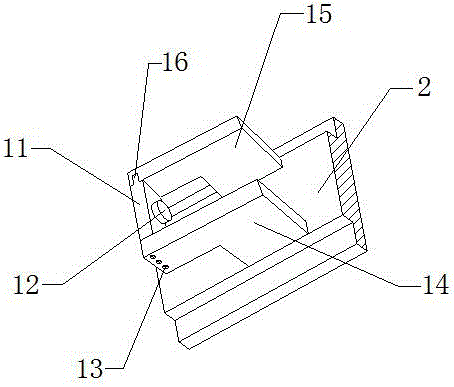

[0024] Specific embodiments: first, the user checks whether the present invention is damaged, and if there is no damage, it can continue to be used. During use, the user uses the fixing hole 13 to install the present invention on the required position, and the user selects the required chuck 12 Finally, the positioning bar 16 is installed in the positioning groove, and the chuck seat 11 is pressed down. When the chuck seat 11 is pressed to the desired position, the user uses the hexagon socket head screw to fix the chuck seat 11 to This realizes fast fixed installation of the chuck 12 and facilitates later replacement.

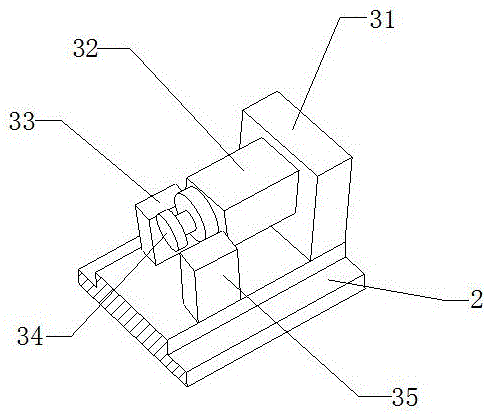

[0025] The user places the roller to be processed in the arc groove on the support block one 4 and the support block two 5, and after fixing one end of the roller to be processed on the chuck 12, the user moves the pneumatic cylinder 32, the pneumatic cylinder The elongation of 32 drives the rubber disc 34 to move, and then the rubber disc 34 is fixed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com