A kind of drilling device and drilling method for any shape hole

A technology of any shape and drill bit, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc. It can solve the problems of single hole shape, large fixture influence, and poor versatility, so as to improve drilling Efficiency and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

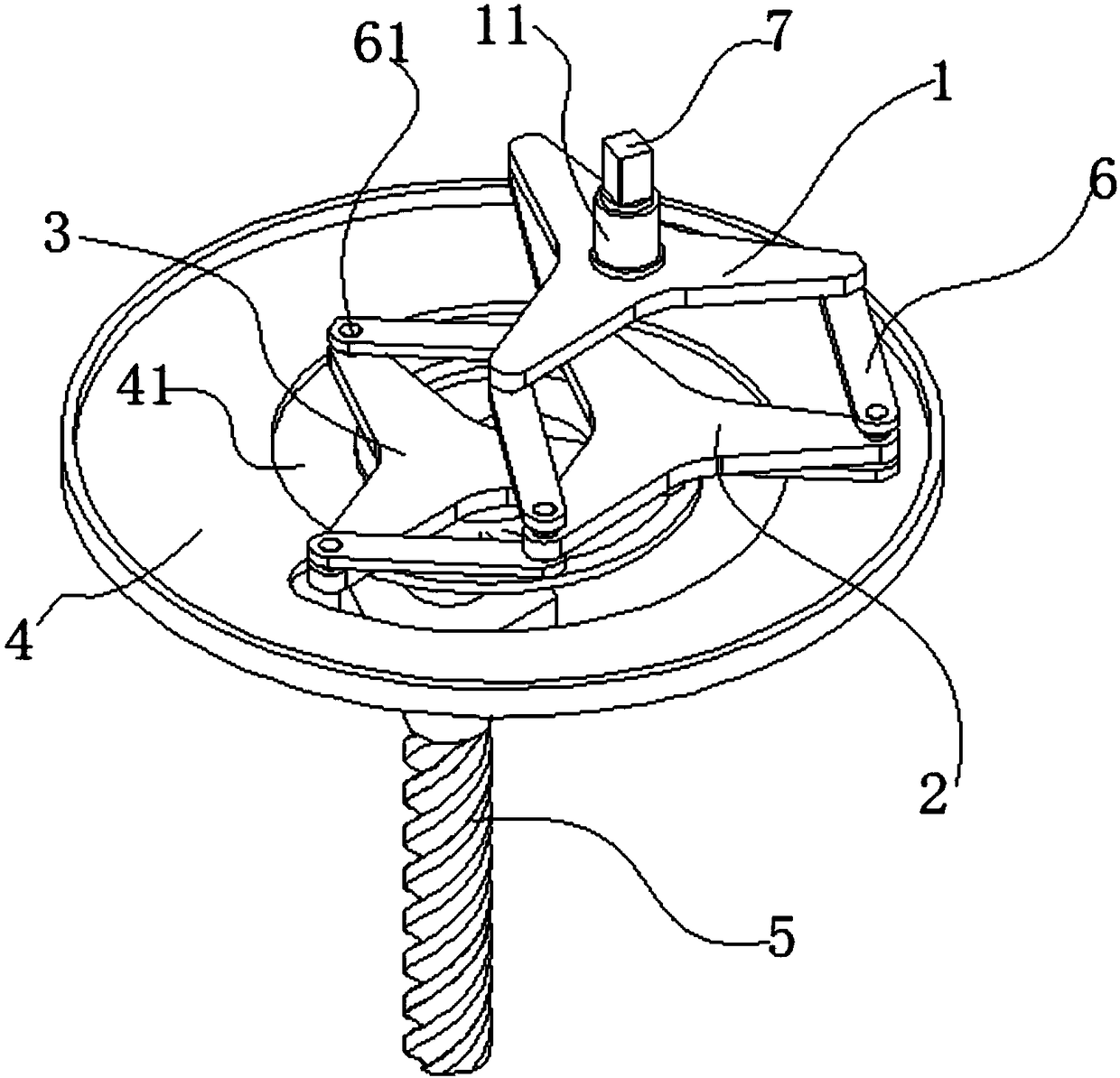

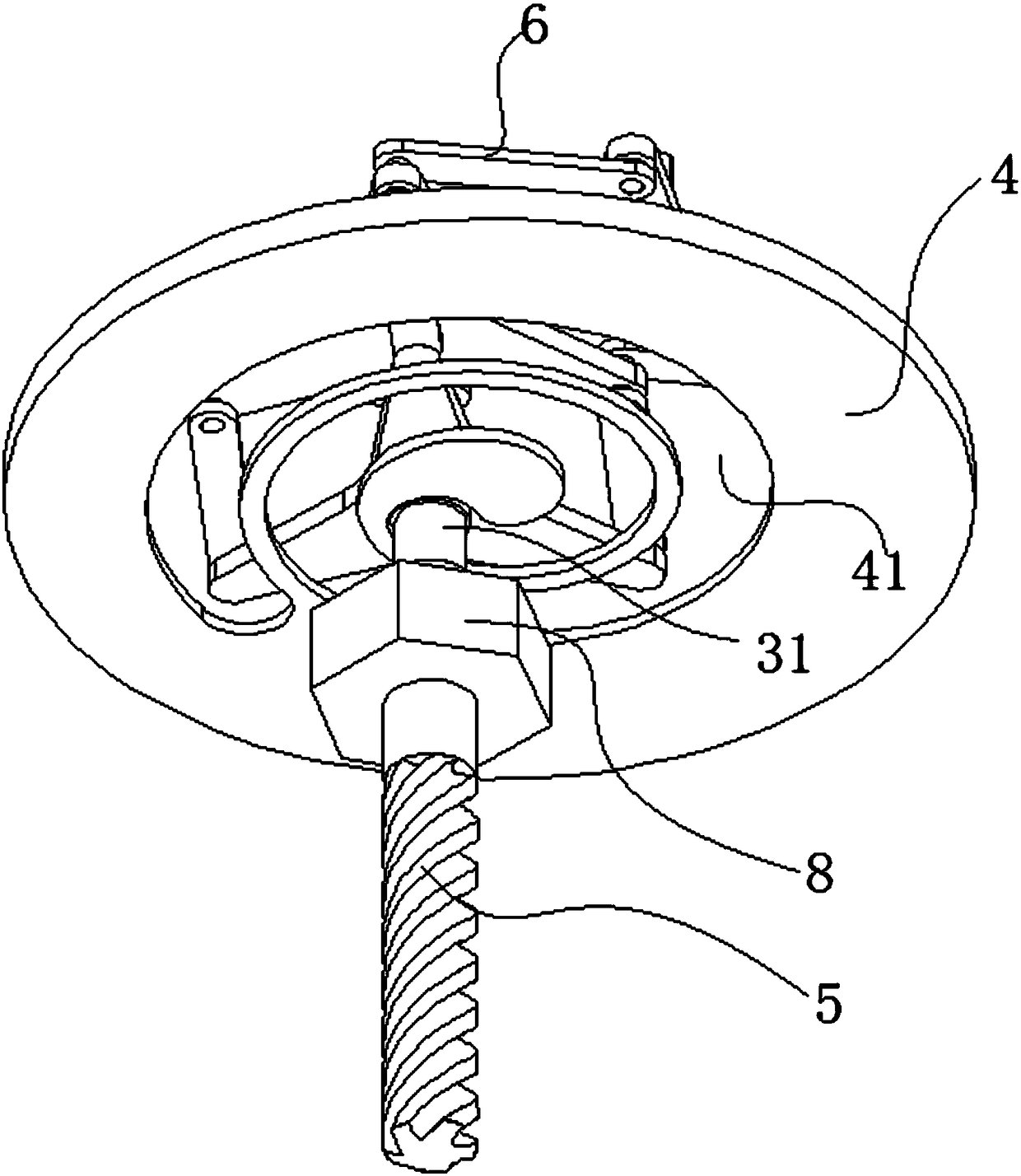

[0058] A kind of drill device of arbitrary shape hole of the present embodiment, comprises drill bit 5, side vane assembly and drill track disc 4; Motion is transformed into surface motion, such as figure 2 As shown, the first layer of the side blade combination is the active side blade 1, and the bottom layer is the driven side blade 3; the middle layers of side blades are the middle side blades 2; the connecting rod 6 and the connecting rod The shaft 61 is hinged. The number of layers of the middle side blade 2 can be adjusted according to the needs of the surface movement area of the workpiece drilling. In this embodiment, the middle side blade 2 is one layer; the hinged connection can transfer the rotation mode of the prime mover down layer by layer The drill bit 5; the drill track disc 4 is stuck at the fixed connection between the side blade assembly and the drill bit 5, limiting the surface movement of the drill bit 5 to the shape set by the drill bit track disc 4; ...

Embodiment 2

[0065] A kind of arbitrarily shaped drill bit device of the present embodiment, the basic structure is the same as embodiment 1, and the improvement is that: the side blades are all in the shape of a triangular or quadrangular or pentagonal or hexagonal star, such as figure 1 , 4 As shown, the triangular star shape can be selected in this embodiment. Compared with the polygonal plate shape, the effect of the star shape is to reduce the visual obstruction of drilling personnel. The visual effect of the triangular star shape is the best, and the efficiency of surface movement is higher; The rod 6 and the connecting rod shaft 61 symmetrically hinge the three distal ends of the triangular star-shaped side blades of two adjacent layers. A driving blade shaft 11 is fixedly connected to the center of the upper surface of the driving side blade 1, and is detachably fixedly connected to the prime mover through the driving blade shaft 11; a driven blade shaft 31 is fixedly connected to ...

Embodiment 3

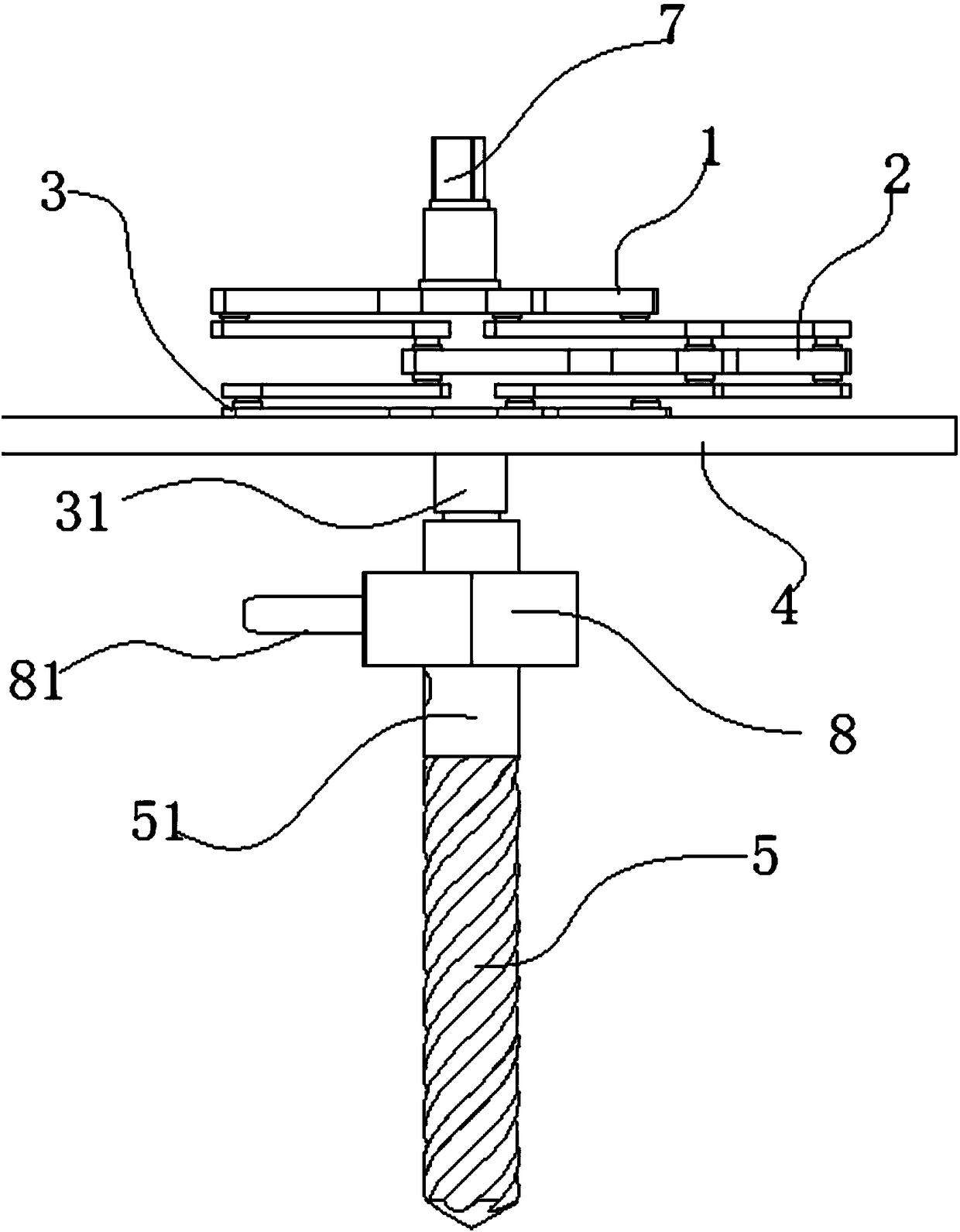

[0073] A kind of arbitrarily shaped drill bit device of the present embodiment, such as image 3 Shown, basic structure is with embodiment 2, and processing is as Figure 7 The shown arc-shaped hole workpiece 20, the steps are:

[0074] Step 1. Installation: insert the prime mover connecting shaft 7 into the groove of the prime mover power end, and detachably connect the driven blade shaft 31 with the fixed end of the drill bit 5;

[0075] Step 2, the design and installation of the drill track disc 4: take a square or circular panel, pierce an arc-shaped hole in its center, and fix it horizontally between two uprights;

[0076] Step 3, positioning: Insert the drill bit 5 into the arc hole, and stick the driven blade shaft 31 into one end of the arc hole;

[0077] Step 4. Drilling: The working end of the drill bit 5 is against the workpiece to be drilled, the prime mover is started, and a single hole is first drilled by holding the positioning block 8;

[0078] Step 5, push:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com