Multihole machining tool of end face of air cylinder sleeve

A hole machining and cylinder liner technology, applied in the field of locomotive cylinder liner end face porous machining tooling and machining tooling, can solve the problems of complicated positioning operation, high consumption cost, increase the height of the object to be processed, etc., to simplify the positioning operation and reduce the positioning Difficulty, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments.

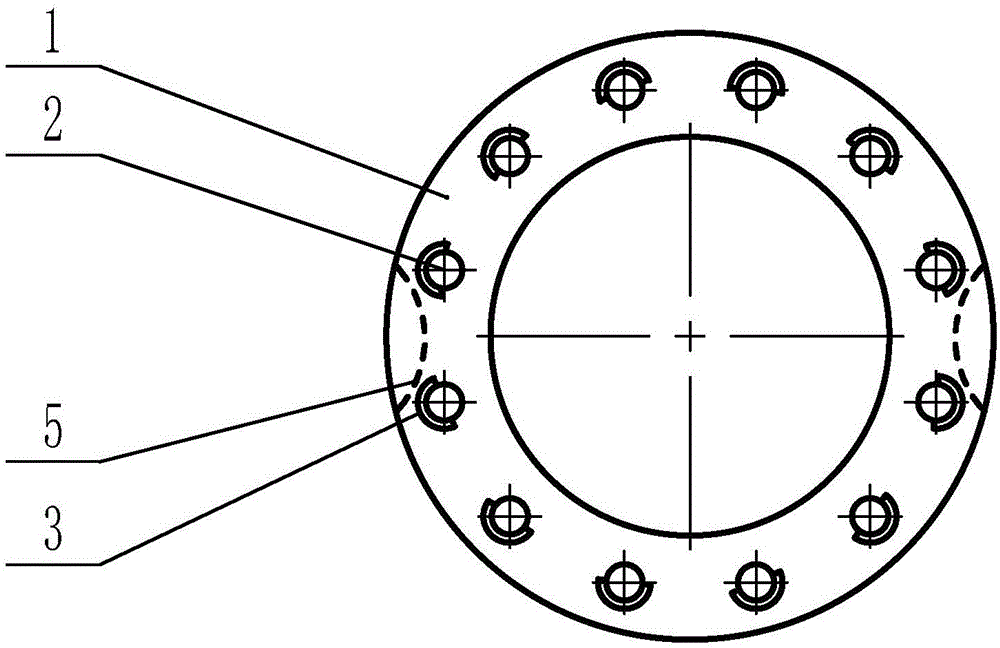

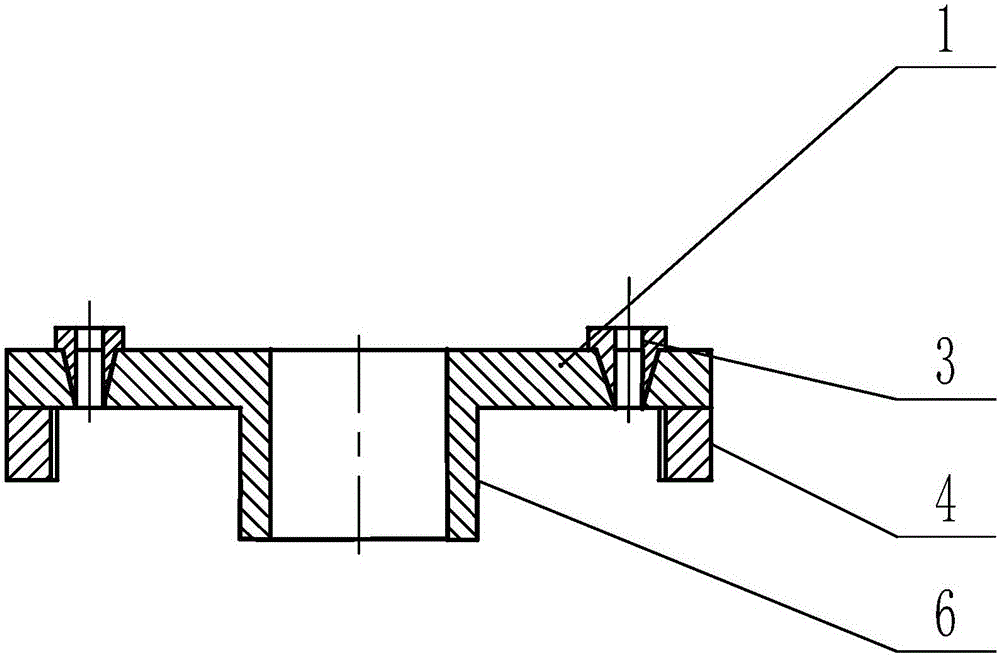

[0017] see figure 1 , figure 2 , a cylinder liner end face porous processing tooling of the present invention, comprising a drill template 1, the drill template 1 is circular cylindrical, and more than one die hole 2 is evenly arranged on the drill template 1 along the same circumference, and the die hole 2 is sleeved There is a drill sleeve 3, and also includes a positioning block 4, which is fixedly connected with the drilling template 1, and the positioning block 4 can be fixedly connected with the drilling template 1 by welding, or can be movably connected with the drilling template 1 by means of bolts, etc. The shape of the block 4 matches that of the arc-shaped notch 5 on the end face of the cylinder liner. When the cylinder liner is assembled with the cylinder liner, the assembly bolts are placed in the arc-shaped notch 5 . There is no need to clamp the parts wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com