A rapid measuring gauge and method for measuring space thermal deformation error of boring and milling machine

A thermal deformation error, boring and milling machine technology, applied in the field of measurement, can solve impractical problems and achieve the effect of being convenient for engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

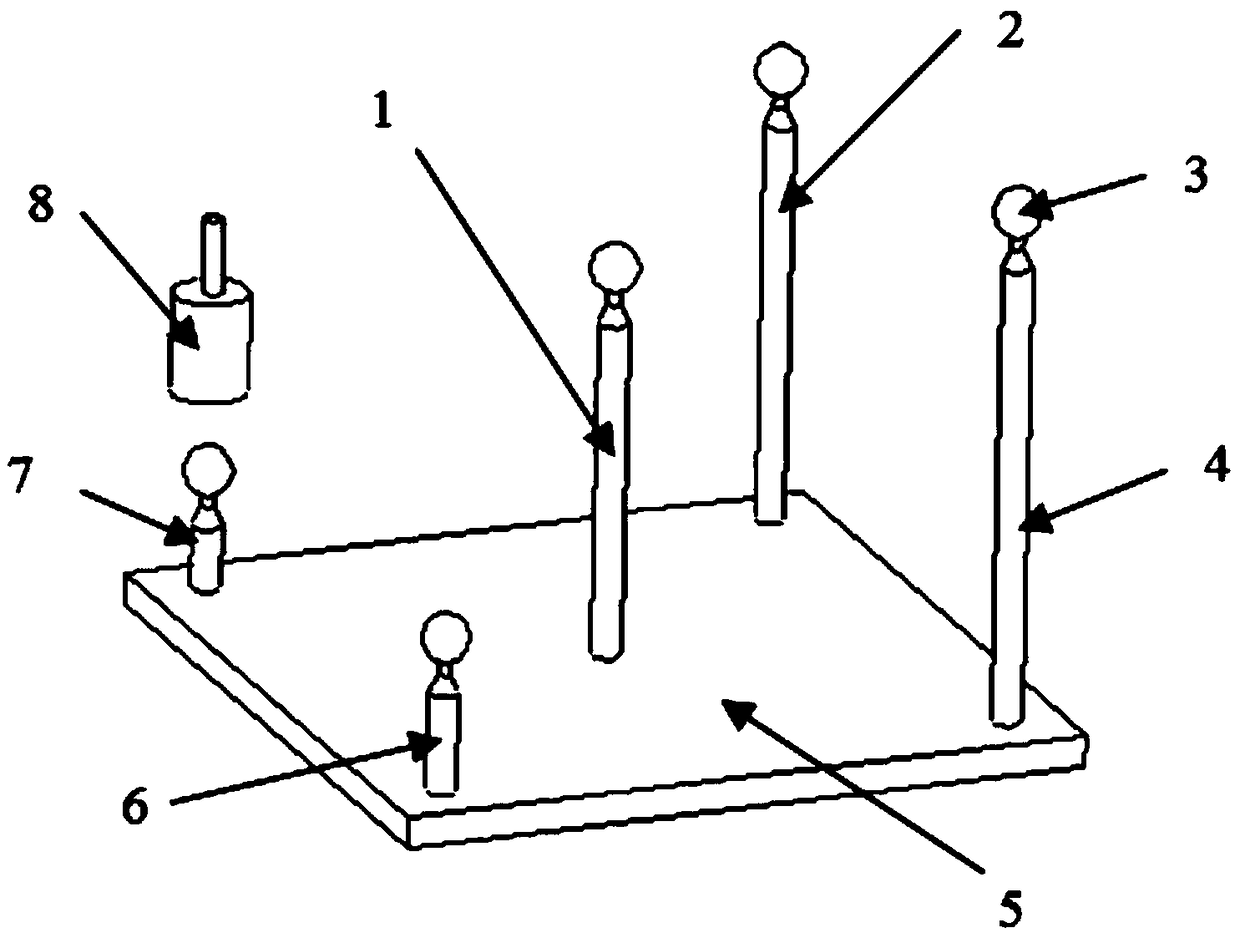

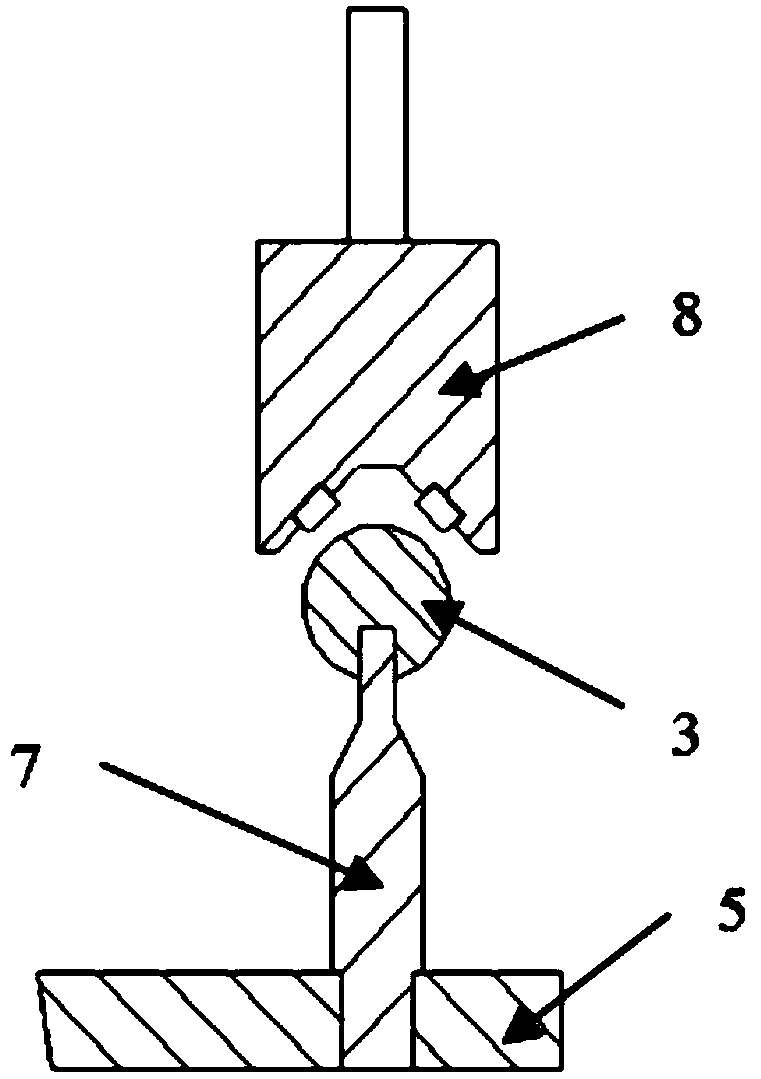

[0041] see figure 1 As shown, the rapid measuring gauge for measuring the space thermal deformation error of the boring and milling machine of the present invention consists of a group of pillars with high-precision standard balls 3 fixed on the top (comprising middle and high pillars 1, high pillars 2, standard balls 3, and middle pillars 4 in this embodiment. And middle pillar pillar 6) is installed on the mounting plate 5 and forms.

[0042] The mounting plate 5 covers a plane size of the required measuring space as far as possible, and the measuring space can be pre-divided according to the machining stroke of the boring and milling machine. The shape of the mounting plate 5 is preferably square.

[0043] In the set of pillars, the heights of the pillars are different from each other. When working, at least five pillars should be selected to be respectively fixed on the four corners of the mounting plate plane and the central areas of the four corners, so as to effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com