Composite small deep hole and blind hole broken nail taking-out device

A take-out device and composite technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as inability to ensure stable installation of parts, high technical level requirements for operators, and high error probability, and achieve simple structure, improved maintenance efficiency, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

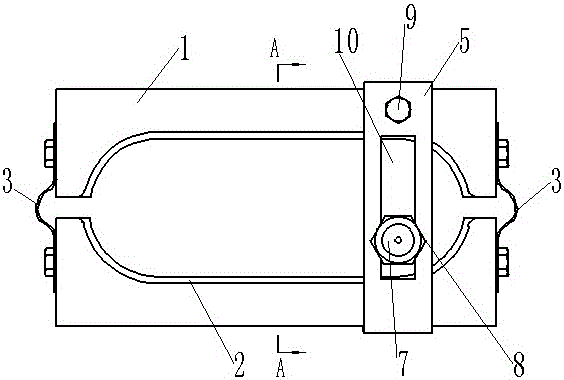

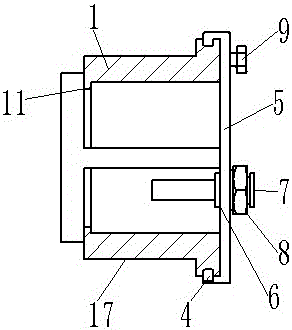

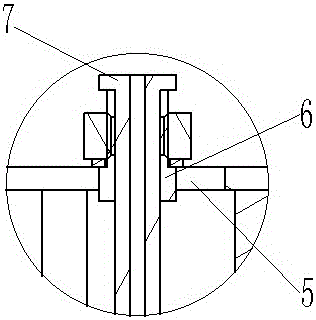

[0010] The embodiment is described in detail in conjunction with the above accompanying drawings, it includes two floating splints 1 that can tightly wrap the aircraft electrical parts, and an elastic connecting plate 3 is fixed with bolts on the two ends of the two floating splints, and the two floating splints The outer wall of the splint is respectively provided with a draw-in groove, and a horizontal slider 5 which is slidably matched with the draw-in groove is installed on the floating splint, and a spring card 4 is installed on the sliding surface of the horizontal slider. A long hole 10, a positioning sleeve 6 is installed from the outside to the inside with a nut 8 in the long hole, and a guide sleeve 7 is installed inward from the nut outer end in the positioning sleeve, and slides toward the floating on the horizontal slide block. A fastening screw 9 is installed on the block. Anti-off bosses 11 are respectively provided under the two floating splints. A layer of fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com